Abstract

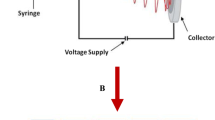

In this study, various concentrations of polyethylene terephthalate (PET) polymeric solution were investigated to produce hollow nanofiber yarn. First, the electrospining apparatus was designed in a way that to put PVA multifilament in the core and to twist PET nanofibers onto multifilament yarn as a sheath simultaneously, followed by dissolving PVA yarn in hot water, PET hollow nanofiber yarn was produced. In this survey, it has been observed that the average thickness of sheath increased by increasing concentrations of PET polymeric solution. Results showed that maximum efficiency of extracting the PVA multifilament from the hollow yarn under certain conditions (concentration of 18 % (w/v) of PET, applied voltage of 10 kV, and flow rate of 0.0526 ml/h) was more than 85 %. The mechanical and physical properties of PET hollow yarns were investigated and indicated that the hollow nanofiber yarns at concentration of 30 % and 18 % polymeric solution had the lowest strength and the highest regain moisture, respectively.

Similar content being viewed by others

Refrerences

D. Li and Y. N. Xia, J. Adv. Mater., 16, 1151 (2004).

D. H. Reneker, A. L. Yarin, H. Fong, and S. Koombhongse, J. Appl. Phys., 87, 4531 (2000).

Y. M. Shin, M. M. Hohman, M. P. Brenner, and G. C. Rutledge, J. Polymer, 42, 9955 (2001).

H. L. Jiang, D. F. Fang, B. J. Hsiao, B. J. Chu, and W. L. Chen, J. Biomater. Sci. Polymer. 15, 279 (2004).

X. H. Zong, K. Kim, D. F. Fang, S. F. Ran, B. S. Hsiao, and B. Chu, Polymer, 43, 4403 (2002).

K. Sawicka, P. Gouma, and S. Simon, Sens Actuators B Chem., 108, 585 (2005).

C. Shin and G. G. Chase, J. Dispers. Sci. Technol., 27, 517 (2006).

C. Shin, G. G. Chase, and D. H. Reneker, J. Colloids Surf A Physicochem. Eng. Asp., 262, 211 (2005).

X. F. Wang, X. M. Chen, K. Yoon, D. F. Fang, B. S. Hsiao, and B. Chu, J. Env. Sci. Tech., 39, 7684 (2005).

A. Babel, D. Li, Y. N. Xia, and S. A. Jenekhe, Macromolecules, 38, 4705 (2005).

Y.-R. Kim, J. Adv. Mater., 15, 2027 (2003).

H. Q. Liu, C. H. Reccius, and H. G. Craighead, Appl. Phys. Lett., 87, 253106 (2005).

X. W. Lou, L. A. Archer, and Z. Yang, J. Adv. Mater., 20, 3987 (2008).

S. E. Skarabalak, J. Chen, Y. Sun, X. Lu, L. Au, C. M. Cobley, and Y. Xia, Acc. Chem. Res., 41, 1587 (2008).

J. Chen, F. Saeki, B. J. Wiley, H. Cang, M. J. Cobb, Z. Y. Li, L. Au, H. Zhang, M. B. Kimmey, X. Li, and Y. Xia, Nano Lett., 5, 473 (2005).

M. Bognitzki H. Q. Hou, M. Ishaque, T. Frese, M. Hellwig, C. Schwarte, A. Schaper, J. H. Wendorff, and A. Greiner, J. Adv. Mater., 12, 637 (2000).

M. X. Wan, Z. X. Wei, Z. M. Zhang, L. J. Zhang, K. Huang, and Y. S. Yang, Synth. Metals, 135, 175 (2003).

I. G. Loscertales, A. Barrero, M. Marquez, R. Spretz, R. Velarde-Ortiz, and G. Larsen, J. Am. Chem. Soc., 126, 5376 (2004).

T. Song, Y. Z. Zhang, T. J. Zhou, C. T. Lim, S. Ramakrishna, and B. Liu, Chem. Phys. Lett., 415, 317 (2005).

J. T. McCann, D. Li, and Y. N. Xia, J. Mater. Chem., 15, 735 (2005).

Z. C. Sun, E. Zussman, A. L. Yarin, J. H. Wendroff, and A. Greiner, J. Adv. Mater., 15, 1929 (2003).

D. Li, A. Babel, S. A. Jenekhe, and Y. N. Xia, J. Adv. Mater., 16, 2062 (2004).

I. G. Loscertales, A. Barrero, I. Guerrero, R. Cortijo, M. Marquez, and A. M. Ganan-Calvo, J. Science, 295, 1695 (2002).

S. Bhargava, Ph. D. Dissertation, The Graduate Faculty of the University of Akron, Ohio, 2007.

S. H. Wu and X. H. Qin, J. Mater. Lett., 106, 204 (2013).

B. Veleirinho, M. F. Rei, and J. A. Lopes-Da-Silvia, J. Polym. Sci. Pol. Phys., 46, 460 (2008).

P. Chegoonian, M. Feiz, S. A. Hosseini. Ravandi, and S. Mallakpour, J. Appl. Polym. Sci., 124, 190 (2012).

A. M. Kenwright, S. K. Peace, R. W. Richards, A. Bunn, and W. A. MacDonald, J. Polymer, 40, 2035 (1999).

A. Merati and M. Okamura, Text. Res. J., 70, 1070 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Javazmi, L., Ravandi, S.A.H. & Ghareaghaji, A.A. Fabrication and characterization of PET nanofiber hollow yarn. Fibers Polym 15, 954–960 (2014). https://doi.org/10.1007/s12221-014-0954-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-0954-9