Abstract

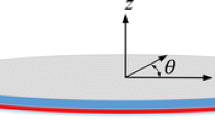

Future space-based imaging systems demand ultra-lightweight mirrors, which would involve a large number of actuators to provide the needed surface correction. These lightweight actuators are required to be integrated with the mirrors to avoid a significant increase in overall areal mass density. This paper presents the fabrication and testing of a linear microactuator and the modeling of an actuated mirror composed of such lightweight actuators. The linear microactuator is driven by a combination of a piezoelectric actuator block and electrostatic comb drive units. A full nonlinear optimization model of a mirror lattice was developed to simulate a lightweight primary with embedded microactuators, which allows for an arbitrarily connected lattice with connector elements having an arbitrary stiffness and actuation response. The modeling yielded a high precision estimation of the mirror shape correction.

Similar content being viewed by others

References

Gullapalli SN, Yang EH, Lih S-S (2003) New technologies for the actuation and control of large aperture lightweight optical quality mirrors. IEEE Aerospace Conference, Big Sky, Montana 4:1717–1728

Hickey GS, Lih SS, Barbee T Jr (2002) Development of nanolaminate thin shell mirrors. Proceedings of SPIE, 4849, Hawaii, USA, 22–23 August, 1502, pp.63–76.

Hollar S, Bergbreiter S, Pister KSJ (2003) Bidirectional linear motors and two-DOF robot leg operation. The 12th International Conference on Solid State Sensors, Actuators and Microsystems, Boston, pp 262–267

Konishi S, Ohno K, Munechika M (2002) Parallel linear actuator system with high accuracy and large stroke. Sens Actuators A 97–98:610–619

Shutov MV, Howard DL, Sandoz EE, Sirota JM, Smith RL, Collins SD (2004) Electrostatic linear microsystem with Long Range Translation. Sens Actuators A 114:379–386

Kwon HN, Jeong SH, Lee SK, Lee JH (2003) Design and characterization of a micromachined linear motor with thermoelastic linkage actuators. Sens Actuators A 103:143–149

de Boer MP, Luck DL, Ashurst WR, Maboudian R, Corwin AD, Walraven JA, Redmond JM (2004) High-performance surface-micromachined linear actuator. J Microelectromech Syst 13:63–74

Toda R, Yang EH (2007) Normally-latched, large-stroke, inchworm microactuator. J Micromechanics and Microengineering 17:1715–1720

Acknowledgement

The research described in this paper was partially carried out under Research and Technology Development program at the Jet Propulsion Laboratory, California Institute of Technology under a contract with the National Aeronautics and Space Administration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shcheglov, K., Jiang, X., Toda, R. et al. Hybrid linear microactuators and their control models for mirror shape correction. J. Micro-Nano Mech. 4, 159–167 (2008). https://doi.org/10.1007/s12213-009-0017-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12213-009-0017-2