Abstract

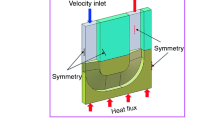

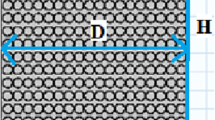

A cold-model vertical multi-tube circulating fluidized bed evaporator was designed and built to conduct a visualization study on the pressure drop of a liquid–solid two-phase flow and the corresponding particle distribution. Water and polyformaldehyde particle (POM) were used as the liquid and solid phases, respectively. The effects of operating parameters such as the amount of added particles, circulating flow rate, and particle size were systematically investigated. The results showed that the addition of the particles increased the pressure drop in the vertical tube bundle. The maximum pressure drop ratios were 18.65%, 21.15%, 18.00%, and 21.15% within the experimental range of the amount of added particles for POM1, POM2, POM3, and POM4, respectively. The pressure drop ratio basically decreased with the increase in the circulating flow rate but fluctuated with the increase in the amount of added particles and particle size. The difference in pressure drop ratio decreased with the increase in the circulating flow rate. As the amount of added particles increased, the difference in pressure drop ratio fluctuated at low circulating flow rate but basically decreased at high circulating flow rate. The pressure drop in the vertical tube bundle accounted for about 70% of the overall pressure drop in the up-flow heating chamber and was the main component of the overall pressure within the experimental range. Three-dimensional phase diagrams were established to display the variation ranges of the pressure drop and pressure drop ratio in the vertical tube bundle corresponding to the operating parameters. The research results can provide some reference for the application of the fluidized bed heat transfer technology in the industry.

Similar content being viewed by others

Abbreviations

- \(\Delta h\) :

-

Height difference between the inlet and outlet of vertical tube bundle (m)

- \(\Delta h_{1}\) :

-

Height difference between the inlet and outlet of up-flow heating chamber (m)

- P 1 :

-

Inlet pressure of the up-flow heating chamber (kPa)

- P 2 :

-

Inlet pressure of the vertical tube bundle (kPa)

- P 3 :

-

Outlet pressure of the vertical tube bundle (kPa)

- P 4 :

-

Outlet pressure of the up-flow heating chamber (kPa)

- \(\Delta P\) :

-

Pressure drop in the vertical tube bundle (kPa)

- \(\Delta P_{1}\) :

-

Pressure drop in the up-flow heating chamber (kPa)

- \(\Delta P_{0}\) :

-

Pressure drop of the single liquid phase flow (kPa)

- \(\Delta P_{{ 0 {\text{s}}}}\) :

-

Pressure drop of the liquid–solid two-phase flow (kPa)

- Q :

-

Circulating flow rate (m3/h)

- R :

-

Ratio of the pressure drop of vertical tube bundle to the overall pressure drop of the up-flow heating chamber (%)

- S :

-

Pressure drop ratio (%)

- S max :

-

Maximum pressure drop ratio of the liquid–solid two-phase flow (%)

- S min :

-

Minimum pressure drop ratio of the liquid–solid two-phase flow (%)

- \(\Delta S\) :

-

Difference in pressure drop ratio (%)

- ε :

-

Amount of added particles

- ρ :

-

Fluid density (kg/m3)

References

Shen C, Cirone C, Yang LC et al (2014) Characteristics of fouling development in shell-and-tube heat exchanger: effects of velocity and installation location. Int J Heat Mass Transf 77:439–448

Müller-Steinhagen H, Zhao Q (1997) Investigation of low fouling surface alloys made by ion implantation technology. Chem Eng Sci 52(19):3321–3332

Pronk P, Infante Ferreira CA, Witkamp GJ (2009) Prevention of fouling and scaling in stationary and circulating liquid–solid fluidized bed heat exchangers: particle impact measurements and analysis. Int J Heat Mass Transf 52:3857–3868

Qi GP, Jiang F (2015) Parametric study of particle distribution in tube bundle heat exchanger. Powder Technol 271:210–220

Bi HY, Duan ML, Gu XH (2011) Study on the performance of a single tube liquid–solid circulating fluidized bed sewage heat exchanger. J Shenyang Jianzhu Univ (Natural Sci) 27(2):331–334 (in Chinese)

Jiang F, Jiang T, Qi GP et al (2019) Effect of flow directions on multiphase flow boiling heat transfer enhanced by suspending particles in a circulating evaporation system. Trans Tianjin Univ. 25(3):201–213

Razzak SA, Agarwal K, Zhu JX (2008) Numerical investigation on the hydrodynamics of an LSCFB riser. Powder Technol 188:42–51

Pronk P, Infante Ferreira CA, Witkamp GJ (2010) Mitigation of ice crystallization fouling in stationary and circulating liquid–solid fluidized bed heat exchangers. Int J Heat Mass Transf 53:403–411

Meijer JJAM (1983) Prevention of calcium sulfate scale deposition by a fluidized bed. Desalination 47(1–3):3–15

Veenman AW (1978) A review of new developments in desalination by distillation processes. Desalination 27(1):21–39

Collado FJ (2018) Hydrodynamics model for the dilute zone of circulating fluidized beds. Powder Technol 328:108–113

Chandel MK, Alappat BJ (2006) Pressure drop and gas bypassing in recirculating fluidized beds. Chem Eng Sci 61:1489–1499

Liu HP, Li JW, Wang Q (2017) Simulation of gas–solid flow characteristics in a circulating fluidized bed based on a computational particle fluid dynamics model. Powder Technol 321:132–142

Grieco E, Marmo L (2006) Predicting the pressure drop across the solids flow rate control device of a circulating fluidized bed. Powder Technol 161:89–97

Grieco E, Marmo L (2008) A model for the pressure balance of a low density circulating fluidized bed. Chem Eng J 140:414–423

Gungor A (2008) Predicting axial pressure profile of a CFB. Chem Eng J 140:448–456

Wen JP, Zhou H, Li XL (2004) Performance of a new vapor–liquid–solid three-phase circulating fluidized bed evaporator. Chem Eng Process 43(1):49–56

Wen JP, Jia XQ, Wang CY et al (2005) Heat transfer and pressure drop of vapor-liquid-solid three-phase boiling flow of binary mixtures. Chem Eng Commun 192:956–971

Cho YJ, Song PS, Lee CG et al (2005) Liquid radial dispersion in liquid-solid circulating fluidized beds with viscous liquid medium. Chem Eng Commun 192:257–271

Zhang SF, Shen ZY, Liu Y (2009) Experimental study on the effect of three-phase distributor on pressure drop in exterior circulating fluidized bed. J Hebei Univ Technol 38:42–45 (in Chinese)

Qi GP, Wang BB, Jiang F (2013) Pressure drop and particles distribution in the vapor–liquid–solid multi-pipe circulating fluidized bed evaporator. Chem Ind Eng 30(3):66–70 (in Chinese)

Zheng Y, Zhu JX (2000) Overall pressure balance and system stability in a liquid–solid circulating fluidized bed. Chem Eng J 79(2):145–153

Hashizume K, Morita S, Nakamura Y et al (2009) Pressure drop in liquid–solid circulating fluidized beds. Heat Transf Asian Res 38(4):248–261

Hashizume K, Kimura Y, Morita S (2009) Analogy between pressure drop and heat transfer in liquid–solid circulating fluidized beds. Heat Transf Asian Res 38(3):183–193

Wang SD, Wang XY, Zhao K et al (2011) Flow characteristics in the high-density circulating fluidized bed risers with different cross sections. Proc Chin Soc Electr Eng 31:8–13 (in Chinese)

Khurram MS, Choi JH, Won YS et al (2016) Relationship between solid flow rate and pressure drop in the riser of a pressurized circulating fluidized bed. J Chem Eng Jpn 49:595–601

Zhang H, Wang JG, Zhang SF (2008) Experimental study of fouling preventing in a horizontal liquid–solid circulating fluidized bed heat exchanger. Chem Equip Technol 29:31–33 (in Chinese)

Liu Y, Zhang SF, Zhang W (2012) Study on particles distribution characteristics through a circulation fluidized bed with the spiral flow generator. Energy Procedia 14:1111–1116

Jiang F, Bian YW, Qi GP et al (2016) Study on the particle distribution of a horizontal multi-tube circulating fluidized bed. Powder Technol 295:272–283

Jiang F, Zhao PL, Qi GP et al (2018) Pressure drop in horizontal multi-tube liquid–solid circulating fluidized bed. Powder Technol 333:60–70

Jiang F, Zhao PL, Qi GP et al (2019) Flow characteristics in a horizontal liquid–solid circulating fluidized bed. Powder Technol 342:24–35

Monji H, Matsui G, Saito T (1995) Pressure drop reduction of liquid-particles two-phase flow with nearly equal density. Multiph Flow 7(2):355–365

Liu Y, Li HB, Wang JG et al (2013) Study on pressure drop of liquid–solid two-phase fluidized bed heat exchanger with Kenics static mixer. Chem Ind Eng Prog 11:2579–2582 (in Chinese)

Qi GP, Jiang F (2015) Numerical investigation on prevention of fouling in the horizontal tube heat exchanger: particle distribution and pressure drop. Desalination 367:112–125

Acknowledgements

This work was supported by the open foundation of State Key Laboratory of Chemical Engineering (SKL-ChE-18B03) and the Municipal Science and Technology Commission of Tianjin (No. 2009ZCKFGX01900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, F., Lv, S., Qi, G. et al. Pressure Drop of Liquid–Solid Two-Phase Flow in the Vertical Tube Bundle of a Cold-Model Circulating Fluidized Bed Evaporator. Trans. Tianjin Univ. 25, 618–630 (2019). https://doi.org/10.1007/s12209-019-00212-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-019-00212-z