Abstract

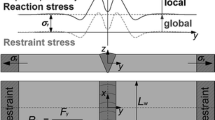

The blind-hole method is the most widely used approach to experimentally determine the distribution of residual stress. This paper aims to improve test accuracy of welding residual stress and conducts an experimental study on the strain release factors involved when using the blind-hole method for Q235 and Q345, two steels commonly used in building structures. The ranges of strain release factors A and B in the elastic stage, the effects of strain release factors on residual stress calculated values, and the plastic corrected strain release factors are analyzed considering of the effect of plastic deformation around the blind hole on measurement accuracy. Finally, a simplified calculation formula to determine strain release factors is proposed for use with the blind-hole method. Results show that in the elastic stage, strain release factor A for Q235 and Q345 ranges from −0.399 to −0.525 and strain release factor B from −0.791 to −0.960. Changing the strain release factors A and B shows that calculated residual tensile stress varies in relation to a decrease in both factor values. However, there is a increase in calculated residual compressive stress with a decrease in the strain release factor A value, but there is an decrease with a decrease in strain release factor B value. Calculated residual stress applied to elastic strain release factors is compared with that applied to amended plastic strain release factors for Q235 steel. The maximum deviation between calculated residual stress and test stress is reduced from 21.1 to 1.0%, and for Q345 steel from 26.5 to 1.2%. It is thus evident that the plastic correction formula proposed in this paper can be used in calculations when conducting a residual stress test.

Similar content being viewed by others

References

Annual Book of ASTM Standard, ASTM Designation: E837-81, 1993,(3)

Mathar J (1934) Determination of initial stresses by measuring the deformations around drilled holes. ASME 56:245–254

Rendler NJ, Vigness I (1966) Hole-drilling strain-gauge method of measuring residual stresses. Exp Mech 6(12):577–586

Bert CW, Thompson GL (1968) A method for measuring planar residual stresses in rectangular orthotropic materials. J Compos Mater 2(2):244–253

Beghini M, Bertini L (1998) Recent advances in the hole drilling method for residual stress measurement. J Mater Eng Perform 7(2):163–172

Vangi D, Tellini S (2010) Hole-drilling strain-gauge method: residual stress measurement with plasticity effects. J Eng Mater Technol 132(1):1–7

Hou HL, Zhu X, Liu RQ (2003) FEM analysis on the strain release factors for measuring welding residual stresses using blind-hole method. J Mech Strength 25(6):632–636 (in Chinese)

Lu CS (1991) Measuring Residual Stress by Hole Drilling Method. Xi’an Jiaotong University Press, Xi’an (in Chinese)

Zhang XP, Wang N (2007) Measurement of welding residual stress in the heavy converter using blind-hole method. Mech Eng 29(3):45–49 (in Chinese)

You M, Zheng XL, Wang FD et al (1999) On suitable testing time of blind hole technique for measuring residual stress. J Univ Hydraul Electric Eng Yichang 21(1):54–57 (in Chinese)

Pei Y, Bao YF, Tang MY (1997) Study on the A, B values in calculating formula of blind-hole technique. J Mech Strength 19(1):18–21 (in Chinese)

Liu XH, Su WG, Zhang YQ et al (2010) Strain releasing factor amendment of hole edge under the yield status. Foundry Technol 31(1):36–39 (in Chinese)

Su LJ, Zhou GT, Liu HS (2016) Calibration and plastic correction on strain releasing coefficients in welding residual stress measurement of LY12 aluminum alloy by blind-hole method. Mater Mech Eng 40(4):48–53 (in Chinese)

Tan MH, Wang RH, Huang YH (2007) Correctional method of strain release coefficients by blind-hole technique to measure residual stress. Hot Work Technol 36(19):65–68 (in Chinese)

Ma WB, Chen SG, Liu HQ et al (2011) FEM simulation of calibration on strain release coefficients in blind hole method. Trans China Weld Inst 32(2):97–100 (in Chinese)

Zhang XH, Zhao HY, Cai ZP et al (2005) FEM analysis and a correction on plasticity effect at the hole edge when using the centre hole method for measuring residual stress. Chin J Mech Eng 41(3):193–200 (in Chinese)

Zheng JY, He W, Shen RJ (2011) Research on finite element calibration technology of calibration coefficients in hole-drilling method. J Mech Eng 47(14):26–31 (in Chinese)

Shi YB, He W, Zheng JY (2010) Research on plasticity modification of strain relief coefficients in Q235 steel. J Zhejiang Univ 44(11):2083–2088 (in Chinese)

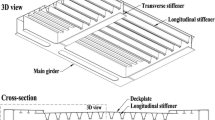

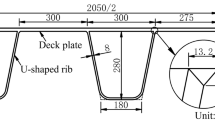

Zhao Q, Guo ZY, Shen XJ et al (2016) Test study on residual stress distribution of hybrid steel u-rib stiffened plates. J Constr Steel Res 121:261–267

Acknowledgements

This study was supported by the National Natural Science Foundation of China (no. 51478120).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Q., Chen, K., Chen, M. et al. Use of Plastic Correction Formula to Improve Accuracy of Welding Residual Stress Test with Blind-Hole Method. Trans. Tianjin Univ. 24, 480–488 (2018). https://doi.org/10.1007/s12209-017-0091-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-017-0091-9