Abstract

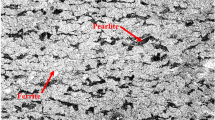

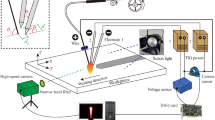

This paper puts forward a new method to achieve flux cored wire TIG welding and uses high-speed photography to analyze the droplet transfer behavior and forces acting on the droplet. The droplet transfer forms include bridging transfer, slag column guided transfer, and non-contact transfer; each of these forms may be observed as the melting position of the welding wire changes. The important role of surface tension in the process of droplet transfer is proposed using static force balance theory and pinch instability theory. The phenomenon of droplet backward swing during welding process could be attributed to the vapor recoil force produced by vapors from the droplet. The welding experiments show that the proposed welding process is stable and that the weld quality produced is good.

Similar content being viewed by others

References

Wang XW (2014) Three-dimensional vision-based sensing of GTAW: a review. Int J Adv Manuf Technol 72(1–4):333–345

Zhang J (2002) Problems and solutions of touch-igniting method in TIG welding. Weld Technol 31(6):59 (in Chinese)

Di XJ, Ji SX, Cheng FJ et al (2015) Effect of cooling rate on microstructure, inclusions and mechanical properties of weld metal in simulated local dry underwater welding. Mater Des 88:505–513

Opderbecke T, Guiheux S (2006) TOPTIG robotic welding process. Electr Weld Mach 36(3):11–15 (in Chinese)

Li H, Yang LJ (2010) Joining processes. Higher Education Press, Beijing (in Chinese)

Li H, Cao WS, Chen BG et al (2000) Metal transfer of gas shielded flux-cored wire and its characteristics. Trans China Weld Inst 21(1):13–16 (in Chinese)

Shi Y, Liu X, Zhang Y et al (2008) Analysis of metal transfer and correlated influences in dual-bypass GMAW of aluminum. Weld J 87(9):229–236

Hermans MJM, Spikes MPG (1993) Characteristic features of the short circuiting arc welding process. Weld Rev Int 12(2):80–86

Lin ML, Eagar TW (1986) Pressures produced by gas tungsten arcs. Metall Trans B 17(3):601–607

Lancaster JF (1985) The physics of welding. Pergamon Press, Oxford

Scheffel B, Goedicke K (1998) In situ-force measurement for the determination of the evaporation rate with high-rate electron beam evaporation. Surf Coat Technol 98(1–3):944–947

Yamamoto K, Tanaka M, Tashiro S et al (2008) Numerical simulation of metal vapor behavior in arc plasma. Surf Coat Technol 202(22–23):5302–5305

Hirano K, Fabbro R, Muller M (2011) Experimental determination of temperature threshold for melt surface deformation during laser interaction on iron at atmospheric pressure. J Phys D Appl Phys 44(43):435402

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51175374) and the Natural Science Foundation of Tianjin (No. 16JCZDJC38700).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., He, T., Liu, Y. et al. Droplet Transfer Behavior of Flux Cored Wire TIG Welding. Trans. Tianjin Univ. 24, 82–90 (2018). https://doi.org/10.1007/s12209-017-0086-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-017-0086-6