Abstract

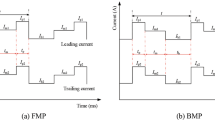

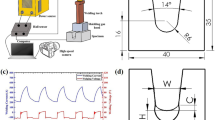

In this work, we utilized high-speed video photography to investigate the arc characteristics, metal transfer behavior, and welding spatter of the pulse-current flux-cored arc welding (P-FCAW) process in the horizontal position. The results indicate the presence of a stable “flux pole” during both the pulse-on and pulse-off periods when the mean current ranged from 140 to 170 A. The existence of this “flux pole” was beneficial for droplet transfer in the “axial droplet transfer” mode. With respect to welding spatter, with an increase in the welding current, we observed three kinds of spatter—explosive spatter, rebounded droplet spatter, and scattering spatter. With an increase in the pulse current from 310.6 to 345.6 A, the deflection of the arc reduced from 30.4° to 16.6°, which positively influenced the arc rigidity, particularly in the horizontal position.

Similar content being viewed by others

References

Ghosh PK, Gupta SR, Randhawa HS (2000) Characteristics of a pulsed-current vertical-up gas metal arc weld in steel. Metall Mater Trans A 31(9):2247–2259

Baune E, Bonnet C, Liu S (2001) Assessing metal transfer stability and spatter severity in flux cored arc welding. Sci Technol Weld Join 6(3):139–148

De Miranda HC, Scotti A, Ferraresi VA (2007) Identification and control of metal transfer in pulsed GMAW using optical sensor. Sci Technol Weld Join 12(3):249–257

Pal K, Pal SK (2011) Effect of pulse parameters on weld quality in pulsed gas metal arc welding: a review. J Mater Eng Perform 20(6):918–931

Yamane S, Xiang S, Kaneko Y et al (2005) Effect of power source characteristic on CO2 short circuiting arc welding. Sci Technol Weld Join 10(3):281–286

Zhu Z, Wu W, Chen Q (2005) Random nature of droplet size and its origins in short circuit CO2 arc welding. Sci Technol Weld Join 10(6):636–642

Randhawa HS, Ghosh PK, Gupta SR (1998) Geometrical characteristics of pulsed current positional GMA Weld. ISIJ Int 38(3):276–284

Baune E (1999) High performance basic flux-cored arc welding consumable development. Colorado School of Mines (Golden), USA

Subramaniam S (1996) Process modeling and analysis for pulsed gas metal arc welding of an aluminum automotive spaceframe. West Virginia University (Morgantown), USA

Wu CS, Chen MA, Lu YF (2005) Effect of current waveforms on metal transfer in pulsed gas metal arc welding. Meas Sci Technol 16(12):2459

Smati Z (1986) Automatic pulsed MIG welding. Metal Constr 18(1):38R–44R

Murakami S, Kitagawa A, Nakajima H et al (1986) A study on horizontal narrow gap welding for heavy plates. Hitachi Zosen Tech Rev 47(1):33–38

Kano M, Hirakoso K, Nomura K. Welding Apparatus with Shifting Magnetic Field: United States Patent 4190760. 1980-02-26

Manabe Y, Zenitani S, Hiromoto Y. Method of welding in the horizontal position and welding apparatus therefor: United States Patent 6023043. 2000-02-08

Henderson I, Seifert K (1976) Investigation of different methods of protecting the molten metal pool in narrow-gap welding of a structural steel for nuclear reactor use. Weld Cut 28(8):291–293

Aloraier A, Ibrahim R, Thomson P (2006) FCAW process to avoid the use of post weld heat treatment. Int J Press Vessel Pip 83(5):394–398

Ghosh PK, Rai BK (1996) Characteristics of pulsed current bead on plate deposit in flux cored GMAW process. ISIJ Int 36(8):1036–1045

Matsuda F, Ushio M, Tsuji T et al (1979) Arc characteristics and metal transfer with flux-cored electrode in CO2 shielding (Report I). Trans JWRI 8(2):187–192

Matsuda F, Ushio M, Tsuji T et al (1980) Arc characteristics and metal transfer for flux-cored electrode in GMA welding (Report II). Trans JWRI 9(1):39–46

Wang Y, Zhang YQ, Wang B et al (2014) Study on metal transfer and welding spatter characteristics of basic flux cored wire. Appl Mech Mater 477:1369–1372

Liu HY, Li ZX, Li H et al (2008) Study on metal transfer modes and welding spatter characteristics of self-shielded flux cored wire. Sci Technol Weld Join 13(8):777–780

Ghosh PK, Dorn L, Kulkarni S et al (2009) Arc characteristics and behaviour of metal transfer in pulsed current GMA welding of stainless steel. J Mater Process Technol 209(3):1262–1274

Ghosh PK, Dorn L et al (2009) Pulsed current gas metal arc welding under different shielding and pulse parameters, Part 2: behaviour of metal transfer. ISIJ Int 49(2):261–269

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, F., Zhang, S., Di, X. et al. Arc Characteristic and Metal Transfer of Pulse Current Horizontal Flux-Cored Arc Welding. Trans. Tianjin Univ. 23, 101–109 (2017). https://doi.org/10.1007/s12209-017-0039-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-017-0039-0