Abstract

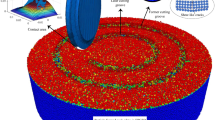

Gaining a thorough understanding of the theoretical principles of rock breaking with a disc cutter is a critical issue in tunnel boring machine (TBM) technology. To fully consider the complexity and importance of the basic principles of rock breaking during tunnel excavation, in this paper we use a new method, the smooth particle hydrodynamics (SPH), to study the rock-breaking mechanism and verify its accuracy and feasibility. Using the SPH method, we induce the rock fragmentation process with two cutters in synchronous and sequential orders. The results show that when the cutters act on rock sequentially, the second indentation influences the crack evolution of the first indentation. With increased cutter spacing, the second crack gradually becomes independent of the first crack. Under synchronous action of the two cutters, a bursiform nucleus is generated beneath the cutters and the area of the nucleus increases with increased cutter spacing. Whether the cutters act on the rock sequentially or synchronously, we found the optimum cutter spacing of our chosen rock type to be 60 mm. Our analyses results show that the efficiency of sequential rock cutting is superior to synchronous cutting, both with respect to crack evolution and cutter force.

Similar content being viewed by others

References

Gong QM, Zhao J, Hefny AM (2006) Numerical simulation of rock fragmentation process induced by two TBM cutters and cutter spacing optimization. Tunn Undergr Space Technol 21:263–270

Gong QM, Jiao YY (2006) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 21:46–55

Gong QM, Zhao J (2005) Numerical modelling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 20:183–191

Moon T, Oh J (2012) A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method. Rock Mech Rock Eng 45(5):837–849

Liu HY, Kou SQ, Lindqvist PA et al (2002) Numerical simulation of the rock fragmentation process induced by indenters. Int J Rock Mech Min Sci 39(4):491–505

Kou SQ, Liu HY, Lindqvist PA et al (2004) Rock fragmentation mechanisms induced by a drill bit. Int J Rock Mech Min Sci 41(3):1–6

Innaurato N, Oggeri C, Oreste PP et al (2007) Experimental and numerical studies of rock breaking with stress confinement. Rock Mech Rock Eng 40(5):429–451

Zilong Zhou, Diyuan Li, Guowei Ma et al (2008) Failure of rock under dynamic compressive loading. J Central South Univ 15:339–343

Zilong Zhou, Yang Zou, Xibing Li et al (2013) Stress evolution and failure process of Brazilian disc under impact. J Central South Univ 20:172–177

Kui Zhang (2010) The studies on rock breaking with shield disc cutters and the vibration characteristics of the disc cutters. Central South University, Changsha (in Chinese)

Hongsu Ma, Hongguang Ji (2011) Experimental study of the effect of joint orientation on fragmentation model and penetration research TBM disc cutters. Chin J Rock Mech Eng 30(1):155–163 (in Chinese)

Hongsu Ma, Lijun Yin, Hongguang Ji (2011) Numerical study of the effect of confining stress on rock fragmentation by TBM cutters. Int J Rock Mech Min Sci 48(6):1021–1033

Jung-Woo C, Seokwon J, Sang-Hwa Y et al (2010) Optimum spacing of TBM disc cutters: a numerical simulation using the three-dimensional dynamic fracturing method. Tunn Undergr Space Technol 25(3):230–244

Zhaohuang Zhang (2001) Survey and drawing of disc cutter of rock tunnel boring machine. Mining Process Equip 11:10–11 (in Chinese)

Jung-Woo Cho, Seokwon Jeon, Ho-Young Jeong et al (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35:37–54

Acknowledgements

This study was supported by the National Natural Science Foundation of China (No. 51275339, No. 51675374 and No. 5157051735).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Bin, H., Guo, W. et al. New Method for Studying Rock-Breaking Mechanism by Disc Cutters. Trans. Tianjin Univ. 23, 147–156 (2017). https://doi.org/10.1007/s12209-017-0033-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-017-0033-6