Abstract

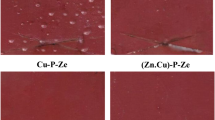

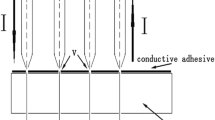

Phenolic formaldehyde(PF)and epoxy(EP)resins are commonly used in electronic packaging. In this paper, high-ohmic resistors(2.2 MΩ, ±0.5%,)with Cr-Si film were coated by PF/EP paint, and the resulting coated resistors were used for heat and humid(HH)experiments. The experimental results show that the corrosion of band-like resistive films is selective and isotropic, and that the corrosion spots in resistive films all form along grooves and extend in the same direction. It is revealed that OH- ions are generated due to the electrochemical reactions of resistive film in HH experiments, so a NaOH aqueous solution with pH about 10 was used to study the effects of absorbed water and OH- ions on PF/EP polymer film. The results indicates that the color of some part on PF/EP polymer film changes due to corrosion, and that the corrosion part of the polymer film is easy to be peeled off. It can be inferred that OH- ions generated in HH experiments may play a catalytic role in the chemical reactions between polymer film and the absorbed water, which accelerates the degradation of PF/EP protection film for a resistor.

Similar content being viewed by others

References

Schiller S, Heisig U, Steinfelder K et al. Cr-Si resistive films produced by magnetron-plasmatron sputtering[J]. Thin Solid Films, 1982, 96(4): 279–284.

Bierbrauer V L, Müller A, Partesch J et al. Mass production of general purpose axial-lead thin film resistors from 0.1 Ohm to 10 Gigaohms[J]. Vakuum-Technik, 1988, 37(1): 5–13.

Gladun C, Heinrich A, Lange F et al. Electrical transport properties of high resistance Cr-Si-O thin films[J]. Thin Solid Films, 1985, 125(1/2): 101–106.

Heinrich A, Gladun C, Schreiber H et al. Electrical properties of heterogeneous CrSi(O,N)thin films[J]. Vacuum, 1990, 41(4/5/6): 1408–1410.

Zelenka J, Chudoba V, Rehák J et al. Thin resistive film with temperature coefficient of resistance close to zero[J]. Thin Solid Films, 1991, 200(2): 239–246.

Heinrich A, Schumann J, Vinzelberg H et al. Nanodisperse CrSi(O, N)thin films—Conductivity, thermopower and applications[J]. Thin Solid Films, 1993, 223(2): 311–319.

Jankowski A F. Characterizing and modeling the apparent anomalous behavior of resistivity in Cr-Si-O thin films[J]. Thin Solid Films, 1998, 332(1/2): 272–276.

Fan W, Mclaurin A W, Henson K E et al. The effects of the process parameters on the electrical and microstructure characteristics of the CrSi thin resistor films: Part I[J]. Thin Solid Films, 1998, 332(1/2): 418–422.

Dong X P, Wu J S. Study on the crystallization of amorphous Cr-Si-Ni thin films using in situ X-ray diffraction[J]. Journal of Materials Science & Technology, 2001, 17(Suppl.1): S43–S46.

Wang X Y, Ma J X, Li C G et al. Structure and electrical properties of quaternary Cr-Si-Ni-W films prepared by ion beam sputter deposition[J]. Journal of Alloys and Compounds, 2014, 604: 12–19.

Dong X P, Wu J S. The influence of zirconium on the crystallization behavior and electrical properties of Cr-Si-Al resistive films[J]. Materials Science and Engineering: A, 2004, 371(1/2): 1–8.

Wang X Y, Zhang Z S, Bai T. Investigation on powder metallurgy Cr-Si-Ta-Al alloy target for high-resistance thin film resistors with low temperature coefficient of resistance[J]. Materials & Design, 2010, 31(3): 1302–1307.

Andziulis A, Andziuliene B, Vaupsas J et al. High stability nano-multilayer resistive films[J]. Surface and Coatings Technology, 2006, 200(22/23): 6212–6217.

Wang X Y, Li C G, Ma J X et al. Deposition of Cr-Si-Ni-Mo films at a low sputtering current and performance of heat and humid resistance[J]. Applied Surface Science, 2014, 289: 538–544.

Zhang Y, Dong X, Wu J S. Corrosion behavior of sputtered Cr-Si-Ni and Cr-Si-Ni-Al resistive films in 0. 1 M NaOH [J]. Applied Surface Science, 2006, 252(8): 2702–2710.

Wang X Y, Zhang Z S, Bai T et al. PF/EP/nano-SiO2 composite paint for resistor[J]. Transactions of Tianjin University, 2009, 15(4): 283–287.

Kuehl R W. Influence of bias humidity testing and application on time-dependent, Arrhenius-law-based stability predictions for thin film resistors[J]. Microelectronics Reliability, 2014, 54(6/7): 1316–1327.

Reid M, Collins M N, Dalton E et al. Testing method for measuring corrosion resistance of surface mount chip resistors[J]. Microelectronics Reliability, 2012, 52(7): 1420–1427.

Roesch W J. Forensic characterization of thin film resistor degradation[J]. Microelectronics Reliability, 2008, 48(7): 958–964.

Wang X Y, Zhang Z S, Shao J Q et al. Effects of metal Ni with catalytic activity on magnetron sputtered Cr-Si resistive film in a heat and humid environment[J]. Surface and Coatings Technology, 2010, 205(7): 2611–2617.

Mertzel E, Koenig J L. Application of FT-IR and NMR to epoxy resins[J]. Advances in Polymer Science, 1986, 75(1): 73–112.

González M G, Cabanelas J C, Baselga J. Applications of FTIR on Epoxy Resins— Identification, Monitoring the Curing Process, Phase Separation and Water Uptake. In: Infrared Spectroscopy — Materials Science, Engineering and Technology[M]. IN TECH, Croatia, 2012.

Sun M L. Principle and Technology of Epoxy Resin Application[M]. China Machine Press, Beijing, China, 2000(in Chinese).

Campaner P, D'Amico D, Longo L et al. Cardanol-based novolac resins as curing agents of epoxy resins[J]. Journal of Applied Polymer Science, 2009, 114(6): 3585–3591.

Unnikrishnan K P, Thachil E T. Studies on the modification of commercial epoxy resin using cardanol-based phenolic resins[J]. Journal of Elastomers and Plastics, 2008, 40(3): 271–286.

Pilato L. Phenolic Resins: A Century of Progress[M]. Springer, New York, USA, 2010.

Nair C P R. Advances in addition-cure phenolic resins[J]. Progress in Polymer Science, 2004, 29(5): 401–498.

von Baeckmann W, Schwenk W, Prinz W. Handbook of Cathodic Corrosion Protection[M]. Gulf Professional Publishing, Houston, USA, 1997.

Heitz E, Kreysa G. Principles of Electrochemical Engineering[M]. VCH, New York, USA, 1986.

Smith M B, March J. March's Advanced Organic Chemistry: Reactions, Mechanisms, and Structure[M]. John Wiley & Sons, New Jersey, USA, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China(No. 61201038).

Wang Xiuyu, born in 1978, male, Dr, associate Prof.

Rights and permissions

About this article

Cite this article

Wang, X., Cheng, Q., Ma, X. et al. Failure behaviors and mechanisms of high-ohmic resistors protected by PF/EP paint in heat and humid environment. Trans. Tianjin Univ. 22, 388–395 (2016). https://doi.org/10.1007/s12209-016-2762-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-016-2762-3