Abstract

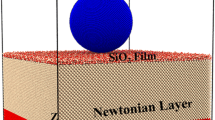

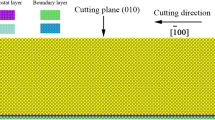

Three-dimensional molecular dynamics simulations are carried out to study the mechanism of nanometric processing of ion implanted monocrystalline silicon surfaces. Lattice transformation is observed during implantation and nano-indentation using radial distribution function and geometric criterion damage detection. Nano-indentation is simulated to study the changes of mechanical property. Implantation analysis shows the existence of amorphous phase. Indentation process shows the lattice evolution, which is beneficial for reducing fractures during processing. The indentation results reveal the reduction of brittleness and hardness of the implanted surface. The ion fluence is in direct proportion to the damage, and inverse to the hardness of the material. Experiments of ion implantation, nanoindentation, nano-scratching and nanometric cutting were carried out to verify the simulation results.

Similar content being viewed by others

References

Neo W K, Kumar A S, Rahman M et al. A review on the current research trends in ductile regime machining[J]. International Journal of Advanced Manufacturing Technology, 2012, 63(5–8): 465–480.

Azimi S, Song J, Dang Z Y et al. Three-dimensional silicon micromachining[J]. Journal of Micromechanics and Microengineering, 2012, 22(11): 113001.

Fang F Z, Venkatesh V C. Diamond cutting of silicon with nanometric finish[J]. CIRP Annals-Manufacturing Technology, 1998, 47(1): 45–49.

Nakasuji T, Kodera S, Hara S et al. Diamond turning of brittle materials for optical components[J]. CIRP Annals-Manufacturing Technology, 1990, 39(1): 89–92.

Yoshino M. Finite element simulation of plane strain plastic-elastic indentation on single-crystal silicon[J]. International Journal of Mechanical Sciences, 2001, 43(2): 313–333.

Fang F Z, Chen Y H, Zhang X D et al. Nanometric cutting of single crystal silicon surfaces modified by ion implantation[J]. CIRP Annals — Manufacturing Technology, 2011, 60(1): 527–530.

Plimpton S. Fast parallel algorithms for short-range molecular dynamics[J]. Journal of Computational Physics, 1995, 117(1): 1–19.

Pelaz L, Marqués L A, Barbolla J. Ion-beam-induced amorphization and recrystallization in silicon[J]. Journal of Applied Physics, 2004, 96(11): 5947–5976.

Fang F Z, Wu H, Liu Y C. Modelling and experimental investigation on nanometric cutting of monocrystalline silicon[J]. International Journal of Machine Tool and Manufacture, 2005, 45(15): 1681–1686.

Tersoff J. New empirical approach for the structure and energy of covalent systems[J]. Physical Review B, 1988, 37(12): 6991–7000.

Stephenson P C L, Radny M W, Smith P V. A modified Stillinger-Weber potential for modelling silicon surfaces [J]. Surface Science, 1996, 366(1): 177–184.

Mylvaganam K, Zhang L C. Nanotwinning in monocrystalline silicon upon nanoscratching[J]. Scripta Materialia, 2011, 65(3): 214–216.

Hofsäss H, Zhang K, Gehrke H G et al. Propagation of ripple patterns on Si during ion bombardment[J]. Physical Review B, 2013, 88(7): 075426.

Morozov S N. Secondary ion emission under the bombardment of Si by multiply charged Siq+ ions[J]. Journal of Surface Investigation. X-ray, Synchrotron and Neutron Techniques, 2012, 6(4): 660–663.

Pharr G M, Oliver W C, Harding D S. New evidence for a pressure-induced phase transformation during the indentation of silicon[J]. Journal of Materials Research, 1991, 6(6): 1129–1130.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Basic Research Program of China (“973” Program, No. 2011CB706703).

Chen Yunhui, born in 1986, female, doctorate student.

Rights and permissions

About this article

Cite this article

Chen, Y., Fang, F., Zhang, X. et al. Molecular dynamics of nanometric processing of ion implanted monocrystalline silicon surfaces. Trans. Tianjin Univ. 20, 203–209 (2014). https://doi.org/10.1007/s12209-014-2336-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-014-2336-1