Abstract

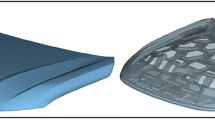

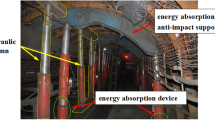

The expansion joints are expected to have movement capacity, bearing capacity for static and dynamic loading, water-tightness, low noise emission and traffic safety. In particular, the failure due to impact loading is the main reason for the observed damages. The problem of dynamic behavior of the expansion joints is so complex that we shall focus our attention on the impact factor for vehicle load that is governed by traffic impact. In order to overcome this difficulty, the cantilever-toothed aluminum joint (finger joint) is one of the promising joints under impact loading. In this study, from the viewpoint of design methodology, numerical studies for impact behavior were conducted for aluminum alloy expansion joints with perforated dowels. The design impact factor for the expansion joints with the perforated dowels against traffic impact loading was examined by using numerical simulations.

Similar content being viewed by others

References

Ramberger G. Structural Bearings and Expansion Joints for Bridges [M]. IABSE-AIPC-IVBH, Zurich, 2002.

Eurocode 9. Design of Aluminum Structures [S]. 2000.

The Aluminum Association. Specifications for Aluminum Structures [S]. 2000.

Japan Road Association. Specifications for Highway Bridges (Part II) [S]. Steel Bridges, 1987 (in Japanese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoda, T., Ayashi, M. Design of bridge expansion joints with perforated dowels under impact loading. Trans. Tianjin Univ. 14, 340–343 (2008). https://doi.org/10.1007/s12209-008-0057-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-008-0057-z