Abstract

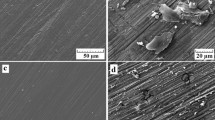

The corrosion resistance of Cu/Diamond composite materials, a combination of copper and diamond, was investigated in aqueous conditions. A 3.5 % NaCl neutral salt spray was employed to assess the corrosion performance of the composite, considering factors such as surface appearance, corrosion rate, and corrosion depth. The results revealed that corrosion predominantly occurred within the copper matrix, while the diamond and interface components remained resistant to corrosion. Micro-galvanic corrosion was identified as the primary corrosion mechanism. Additionally, the incorporation of 5 % diamond particles led to a notable improvement in corrosion resistance, reaching 93.7 %. Although the salt spray environment did induce some changes in the composite surface, it did not significantly impact the overall properties of the composite.

Similar content being viewed by others

References

B. Denkena, B. Bergmann and R. Lang, Influence of the powder metallurgy route on the mechanical properties of Cu–Cr–diamond composites, SN Appl. Sci., 4 (6) (2022) 161, doi: https://doi.org/10.1007/s42452-022-05048-2.

L. Constantin et al., Additive manufacturing of copper/diamond composites for thermal management applications, Manuf. Lett., 24 (2020) 61–66, doi: https://doi.org/10.1016/j.mfglet.2020.03.014.

Z. Xie, H. Guo, X. Zhang and S. Huang, Corrosion behavior of pressure infiltration diamond/Cu composites in neutral salt spray, Materials (Basel), 13 (8) (2020) 1–11, doi: https://doi.org/10.3390/MA13081847.

W. Tian, L. Liu, F. Meng, Y. Liu, Y. Li and F. Wang, The failure behaviour of an epoxy glass flake coating/steel system under marine alternating hydrostatic pressure, Corros. Sci., 86 (2014) 81–92, doi: https://doi.org/10.1016/j.corsci.2014.04.038.

S. M. Milić, M. M. Antonijević, S. M. Šerbula and G. D. Bogdanović, Influence of benzotriazole on corrosion behaviour of CuAlNiSi alloy in alkaline medium, Corros. Eng. Sci. Technol., 43 (1) (2008) 30–37, doi: https://doi.org/10.1179/174327808X286329.

P. Sangaravadivel, G. Rajamurugan and P. Krishnasamy, Significance of Tungsten disulfide on the mechanical and machining characteristics of phosphor bronze metal matrix composite, Adv. Compos. Lett., 29 (2020) 1–13, doi: https://doi.org/10.1177/2633366x20962496.

N. Poulose, P. Selvakumar, J. T. Philip and J. George, Tribological, mechanical and thermal response of diamond micro-particles reinforced copper matrix composites fabricated by powder metallurgy, Mater. Res. Express, 10 (1) (2023) 015003, doi: https://doi.org/10.1088/2053-1591/acb1a0.

X. Li, S. Yan, X. Chen, Q. Hong and N. Wang, Microstructure and mechanical properties of graphene-reinforced copper matrix composites prepared by in-situ CVD, ball-milling, and spark plasma sintering, J. Alloys Compd., 834 (2020) 155182, doi: https://doi.org/10.1016/j.jallcom.2020.155182.

O. Papadopoulou and P. Vassiliou, The influence of archaeometallurgical copper alloy castings microstructure towards corrosion evolution in various corrosive media, Corros. Mater. Degrad., 2 (2) (2021) 227–247, doi: https://doi.org/10.3390/cmd2020013.

A. Aballe, M. Bethencourt, F. J. Botana, M. J. Cano and M. Marcos, Localized alkaline corrosion of alloy AA5083 in neutral 3.5 % NaCl solution, Corros. Sci., 43 (9) (2001) 1657–1674, doi: https://doi.org/10.1016/S0010-938X(00)00166-9.

E. Martinez-Lombardia, L. Lapeire, I. De Graeve, K. Verbeken, L. A. I. Kestens and H. Terryn, Study of the influence of the microstructure on the corrosion properties of pure copper, Mater. Corros., 67 (8) (2016) 847–856, doi: https://doi.org/10.1002/maco.201508719.

E. McCafferty, Validation of corrosion rates measured by the Tafel extrapolation method, Corros. Sci., 47 (12) (2005) 3202–3215, doi: https://doi.org/10.1016/j.corsci.2005.05.046.

M. A. Amin and M. M. Ibrahim, Corrosion and corrosion control of mild steel in concentrated H2SO4 solutions by a newly synthesized glycine derivative, Corros. Sci., 53 (3) (2011) 873–885, doi: https://doi.org/10.1016/j.corsci.2010.10.022.

H. Rezagholi, M. Mirjani, M. Abdi and S. Borji, Properties of copper/nano-diamond composites upon pre/post heat treatment, Mater. Res. Express, 6 (2019) 125007, doi: https://doi.org/10.1088/2053-1591/ab547e.

O. Sanni and A. P. I. Popoola, Data on environmental sustainable corrosion inhibitor for stainless steel in aggressive environment, Data Br., 22 (2019) 451–457, doi: https://doi.org/10.1016/j.dib.2018.11.134.

A. Jamwal, P. P. Seth, D. Kumar, R. Agrawal, K. K. Sadasivuni and P. Gupta, Microstructural, tribological and compression behaviour of copper matrix reinforced with Graphite-SiC hybrid composites, Mater. Chem. Phys., 251 (2020) 123090, doi: https://doi.org/10.1016/j.matchemphys.2020.123090.

N. Kumar, A. Bharti, M. Dixit and A. Nigam, Effect of powder metallurgy process and its parameters on the mechanical and electrical properties of copper-based materials: literature review, Powder Metall. Met. Ceram., 59 (7–8) (2020) 401–410, doi: https://doi.org/10.1007/s11106-020-00174-1.

W. B. Johnson and B. Sonuparlak, Diamond/Al metal matrix composites formed by the pressureless metal infiltration process, J. Mater. Res., 8 (5) (1993) 1169–1173, doi: https://doi.org/10.1557/JMR.1993.1169.

G. Wu, L. Sun, W. Dai, L. Song and A. Wang, Influence of interlayers on corrosion resistance of diamond-like carbon coating on magnesium alloy, Surf. Coatings Technol., 204 (14) (2010) 2193–2196, doi: https://doi.org/10.1016/j.surfcoat.2009.12.009.

T. Q. Tran et al., 3D printing of highly pure copper, Metals (Basel), 9 (7) (2019) 12–20, doi: https://doi.org/10.3390/met9070756.

Z. A. Hamid, M. H. Gomaa and H. B. Hassan, Corrosion performance of copper-diamond composites in different aqueous solutions, Am. J. Electromagn. Appl., 4 (2) (2016) 39–49, doi: https://doi.org/10.11648/j.ajea.20160402.15.

J. H. Liu et al., Impact of annealing temperature on the microstructure, microhardness, tribological properties and corrosion resistance of Ni-Mo/diamond composites, Appl. Surf. Sci., 541 (2021) 148367, doi: https://doi.org/10.1016/j.apsusc.2020.148367.

J. H. Liu, Z. L. Pei, W. B. Shi, Y. D. Liu, J. Gong and C. Sun, Studies on preparation, microstructure, mechanical properties and corrosion resistance of Ni-Mo/micron-sized diamond composite coatings, Surf. Coatings Technol., 385 (2019) (2020) 125451, doi: https://doi.org/10.1016/j.surfcoat.2020.125451.

X. Zhang, M. Xu, S. Cao, W. Chen, W. Yang and Q. Yang, Enhanced thermal conductivity of diamond/copper composite fabricated through doping with rare-earth oxide Sc2O3, Diam. Relat. Mater., 104 (2019) (2020) 107755, doi: https://doi.org/10.1016/j.diamond.2020.107755.

S. S. Bujari and D. R. V. Kurahatti, A review on processing and tribological properties of metal matrix composites, IJAETMAS, 3 (1) (2016) 302–310.

Author information

Authors and Affiliations

Corresponding author

Additional information

Nixon Poulose is a research scholar in the Department of Mechanical Engineering, PSN College of Engineering and Technology, Tirunelveli. His research interests include Tribology, composite materials and optimization.

P. Selvakumar is a Professor in the Department of Mechanical Engineering, PSN College of Engineering and Technology, Tirunelveli. He received his Ph.D. in Nano fluid Heat transfer from National Institute of Technology, Tiruchirappalli.

Rights and permissions

About this article

Cite this article

Poulose, N., Selvakumar, P. Assessment of corrosion resistance and reliability of Cu/diamond composite materials in aquatic environment. J Mech Sci Technol 38, 2439–2446 (2024). https://doi.org/10.1007/s12206-024-0422-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0422-4