Abstract

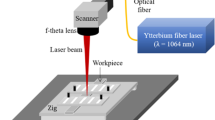

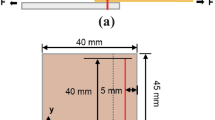

The choice of welding path in joining battery connections plays a crucial role in the bonding strength, which in turn affects battery performance. A commonly employed welding path in laser welding is the circular wobbling path. Our prior study revealed that the hatching path in laser welding, which is hardly reported in the literature, offers a flexible welding pattern and sufficient weld strength, especially for thin specimens. This study conducted a comparative analysis of circular and hatch welding paths concerning their microstructure, mechanical properties, and electrical characteristics. Upon observing the surfaces of the two types of welds, it becomes evident that the hatch welding path results in a superior weld appearance with less spatter formation near the welding zone in comparison to the circular path. Furthermore, an examination of the cross-sections reveals a significant disparity in the interdiffusion between the welding materials. While the circular path yields a non-uniform chemical diffusion of the case material within the welded tab, the hatching path exhibits a periodic upward penetration of the case material into the tab at the welding lines. This discrepancy leads to a distinctive distribution of hardness, electrical resistance, and mechanical strength in the welds, with the desired properties attributed to the hatch welding path. Through this comparative analysis, the study unveils the influence of the laser beam deflection path on the overall weld quality.

Similar content being viewed by others

References

S. Megahed and W. Ebner, Lithium-ion battery for electronic applications, J. Power Sources, 54(1) (1995) 155–162, doi: https://doi.org/10.1016/0378-7753(94)02059-C.

N. Nitta, F. Wu, J. T. Lee and G. Yushin, Li-ion battery materials: Present and future, Mater. Today, 18(5) (2015) 252–264, doi: https://doi.org/10.1016/j.mattod.2014.10.040.

T. Chen et al., Applications of lithium-ion batteries in grid-scale energy storage systems, Trans. Tianjin Univ., 26(3) (2020) 208–217, doi: https://doi.org/10.1007/s12209-020-00236-w.

R. Ravi, Importance of Lithium Ion Battery in BMS of Electric Vehicles, ResearchGate (2020) doi: https://doi.org/10.13140/RG.2.2.20898.66241.

A. Yoshino, Development of the Lithium-Ion Battery and Recent Technological Trends, Elsevier, Netherlands (2014) doi: https://doi.org/10.1016/B978-0-444-59513-3.00001-7.

T. Fujita and K. Toda, Microdisplacement measurement using a liquid-delay-line oscillator, Japanese J. Appl. Physics, Part 1 Regul. Pap. Short Notes Rev. Pap., 42(9) (2003) 6131–6134, doi: https://doi.org/10.1143/jjap.42.6131.

J. B. Goodenough and K. Mizushima, Fast ION Conductors, United States Patent (1982) https://patents.google.com/patent/US4357215A/en.

R. Yazami and P. Touzain, A reversible graphite-lithium negative electrode for electrochemical generators, J. Power Sources, 9(3) (1983) 365–371, doi: https://doi.org/10.1016/0378-7753(83)87040-2.

L. N. Trinh and D. Lee, The effect of using a metal tube on laser welding of the battery case and the tab for lithium-ion battery, Materials (Basel), 13(19) (2020) 4460, doi: https://doi.org/10.3390/ma13194460.

D. Lee, R. Patwa, H. Herfurth and J. Mazumder, High speed remote laser cutting of electrodes for lithium-ion batteries: anode, J. Power Sources, 240 (2013) 368–380, doi: https://doi.org/10.1016/j.jpowsour.2012.10.096.

D. Lee, B. Oh and J. Suk, The effect of compactness on laser cutting of cathode for lithium-ion batteries using continuous fiber laser, Appl. Sci., 9(1) (2019) 205, doi: https://doi.org/10.3390/app9010205.

D. Lee, R. Patwa, H. Herfurth and J. Mazumder, Computational and experimental studies of laser cutting of the current collectors for lithium-ion batteries, J. Power Sources, 210 (2012) 327–338, doi: https://doi.org/10.1016/j.jpowsour.2012.03.030.

J. Godek, Joining lithium–ion batteries into packs using small-scale resistance spot welding, Weld. Int., 27(8) (2013) 616–622, doi: https://doi.org/10.1080/09507116.2011.606148.

D. Lee and S. Ahn, Investigation of laser cutting width of Li-CoO2 coated aluminum for lithium-ion batteries, Appl. Sci., 7(9) (2017) 914, doi: https://doi.org/10.3390/app7090914.

A. Das, D. Li, D. Williams and D. Greenwood, Weldability and shear strength feasibility study for automotive electric vehicle battery tab interconnects, J. Brazilian Soc. Mech. Sci. Eng., 41(1) (2019) 1–14, doi: https://doi.org/10.1007/s40430-018-1542-5.

Y. T. You and J. W. Kim, Fiber laser welding properties of copper materials for secondary batteries, Medziagotyra, 23(4) (2017) 398–403, doi: https://doi.org/10.5755/j01.ms.23.4.16316.

M. F. R. Zwicker, M. Moghadam, W. Zhang and C. V. Nielsen, Automotive battery pack manufacturing–A review of battery to tab joining, J. Adv. Join. Process., 1(2019) (2020) 100017, doi: https://doi.org/10.1016/j.jajp.2020.100017.

Y. Xue, R. Shen, S. Ni, M. Song and D. Xiao, Fabrication, microstructure and mechanical properties of Al-Fe intermetallic particle reinforced Al-based composites, J. Alloys Compd., 618 (2015) 537–544, doi: https://doi.org/10.1016/j.jallcom.2014.09.009.

C. Dharmendra, K. P. Rao, J. Wilden and S. Reich, Study on laser welding-brazing of zinc coated steel to aluminum alloy with a zinc based filler, Mater. Sci. Eng. A, 528(3) (2011) 1497–1503, doi: https://doi.org/10.1016/j.msea.2010.10.050.

A. Mathieu et al., Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire), Opt. Laser Technol., 39(3) (2007) 652–661, doi: https://doi.org/10.1016/j.optlastec.2005.08.014.

M. Pouranvari, Critical assessment: dissimilar resistance spot welding of aluminium/steel: challenges and opportunities, Mater. Sci. Technol. (United Kingdom), 33(15) (2017) 1705–1712, doi: https://doi.org/10.1080/02670836.2017.1334310.

Z. Wan, H. P. Wang, N. Chen, M. Wang and B. E. Carlson, Characterization of intermetallic compound at the interfaces of Al-steel resistance spot welds, J. Mater. Process. Technol., 242 (2017) 12–23, doi: https://doi.org/10.1016/j.jmatprotec.2016.11.017.

J. Kang, H. M. Rao, D. R. Sigler and B. E. Carlson, Tensile and fatigue behaviour of AA6022-T4 to if steel resistance spot welds, Procedia Struct. Integr., 5 (2017) 1425–1432, doi: https://doi.org/10.1016/j.prostr.2017.07.207.

J. Chen, X. Yuan, Z. Hu, T. Li, K. Wu and C. Li, Improvement of resistance-spot-welded joints for DP 600 steel and A5052 aluminum alloy with Zn slice interlayer, J. Manuf. Process., 30 (2017) 396–405, doi: https://doi.org/10.1016/j.jmapro.2017.10.009.

N. Chen, M. Wang, H. P. Wang, Z. Wan and B. E. Carlson, Microstructural and mechanical evolution of Al/steel interface with Fe2Al5 growth in resistance spot welding of aluminum to steel, J. Manuf. Process., 34 (2018) 424–434, doi: https://doi.org/10.1016/j.jmapro.2018.06.024.

P. Podržaj, I. Polajnar, J. Diaci and Z. Kariž, Overview of resistance spot welding control, Sci. Technol. Weld. Join., 13(3) (2008) 215–224, doi: https://doi.org/10.1179/174329308X283893.

P. Prangnell, F. Haddadi and Y. C. Chen, Ultrasonic spot welding of aluminium to steel for automotive applications-microstructure and optimisation, Mater. Sci. Technol., 27(3) (2011) 617–624, doi: https://doi.org/10.1179/026708310X520484.

H. T. Fujii, Y. Goto, Y. S. Sato and H. Kokawa, Microstructure and lap shear strength of the weld interface in ultrasonic welding of Al alloy to stainless steel, Scr. Mater., 116 (2016) 135–138, doi: https://doi.org/10.1016/j.scriptamat.2016.02.004.

F. Haddadi, D. Strong and P. B. Prangnell, Effect of zinc coatings on joint properties and interfacial reactions in aluminum to steel ultrasonic spot welding, JOM, 64(3) (2012) 407–413, doi: https://doi.org/10.1007/s11837-012-0265-9.

M. Shakil, N. H. Tariq, M. Ahmad, M. A. Choudhary, J. I. Akhter and S. S. Babu, Effect of ultrasonic welding parameters on microstructure and mechanical properties of dissimilar joints, Mater. Des., 55 (2014) 263–273, doi: https://doi.org/10.1016/j.matdes.2013.09.074.

J. Mazumder, Laser heat treatment: the state of the art, JOM, 35(5) (1983) 18–26, doi: https://doi.org/10.1007/BF03338273.

R. E. Wagner, Laser drilling mechanics, J. Appl. Phys., 45(10) (1974) 4631–4637, doi: https://doi.org/10.1063/1.1663102.

A. Mahrle and E. Beyer, Theoretical aspects of fibre laser cutting, J. Phys. D. Appl. Phys., 42 (17) (2009) doi: https://doi.org/10.1088/0022-3727/42/17/175507.

D. Y. You, X. D. Gao and S. Katayama, Review of laser welding monitoring, Sci. Technol. Weld. Join., 19(3) (2014) 181–201, doi: https://doi.org/10.1179/1362171813Y.0000000180.

S. S. Lee, T. H. Kim, S. J. Hu, W. W. Cai and J. A. Abell, Joining technologies for automotive lithium-ion battery manufacturing - A review, ASME 2010 Int. Manuf. Sci. Eng. Conf. MSEC 2010, 1 (2010) 541–549, doi: https://doi.org/10.1115/MSEC2010-34168.

L. H. Shah, F. Khodabakhshi and A. Gerlich, Effect of beam wobbling on laser welding of aluminum and magnesium alloy with nickel interlayer, J. Manuf. Process., 37(2018) (2019) 212–219, doi: https://doi.org/10.1016/j.jmapro.2018.11.028.

S. V. Kuryntsev and A. K. Gilmutdinov, The effect of laser beam wobbling mode in welding process for structural steels, Int. J. Adv. Manuf. Technol., 81(9–12) (2015) 1683–1691, doi: https://doi.org/10.1007/s00170-015-7312-y.

L. Wang, M. Gao, C. Zhang and X. Zeng, Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy, Mater. Des., 108 (2016) 707–717, doi: https://doi.org/10.1016/j.matdes.2016.07.053.

C. L. Druzgalski, A. Ashby, G. Guss, W. E. King, T. T. Roehling and M. J. Matthews, Process optimization of complex geometries using feed forward control for laser powder bed fusion additive manufacturing, Addit. Manuf., 34 (2020) 101169, doi: https://doi.org/10.1016/j.addma.2020.101169.

L. Li and S. Anand, Hatch pattern based inherent strain prediction using neural networks for powder bed fusion additive manufacturing, J. Manuf. Process., 56 (2020) 1344–1352, doi: https://doi.org/10.1016/j.jmapro.2020.04.030.

N. Nadammal et al., Effect of hatch length on the development of microstructure, texture and residual stresses in selective laser melted superalloy Inconel 718, Mater. Des., 134 (2017) 139–150, doi: https://doi.org/10.1016/j.matdes.2017.08.049.

L. N. Trinh and D. Lee, The characteristics of laser welding of a thin aluminum tab and steel battery case for lithium-ion battery, Metals, 10(6) (2020) 842, doi: https://doi.org/10.3390/met10060842.

A. Mazzoli and O. Favoni, Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by scanning electron microscopy and image processing program, Powder Technol., 225 (2012) 65–71, doi: https://doi.org/10.1016/j.powtec.2012.03.033.

A. F. H. Kaplan and J. Powell, Spatter in laser welding, J. Laser Appl., 23(3) (2011) 032005, doi: https://doi.org/10.2351/1.3597830.

L. N. Trinh and D. Lee, Welding of thin tab and battery case for lithium-ion battery cylindrical cell using nanosecond pulsed fiber laser, Journal of Welding and Joining, 38(4) (2020) 389–394, doi: https://doi.org/10.5781/jwj.2020.38.4.8.

B. Bagheri, M. Abbasi, F. Sharifi and A. Abdollahzadeh, Investigation into novel multipass friction stir vibration brazing of carbon steels, Mater. Manuf. Process., 37(8) (2022) 921–932, doi: https://doi.org/10.1080/10426914.2021.2006220.

A. H. Vaneghi, B. Bagheri, A. Shamsipur, S. E. Mirsalehi and A. Abdollahzadeh, Investigations into the formation of intermetallic compounds during pinless friction stir spot welding of AA2024-Zn-pure copper dissimilar joints, Weld. World, 66(11) (2022) 2351–2369, doi: https://doi.org/10.1007/S40194-022-01366-6/FIGURES/12.

A. Abdollahzadeh, B. Bagheri, A. H. Vaneghi, A. Shamsipur and S. E. Mirsalehi, Advances in simulation and experimental study on intermetallic formation and thermomechanical evolution of Al-Cu composite with Zn interlayer: effect of spot pass and shoulder diameter during the pinless friction stir spot welding process, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 237(6) (2022) 1475–1494, doi: https://doi.org/10.1177/14644207221146981.

X. Ao, H. Xia, J. Liu and Q. He, Simulations of microstructure coupling with moving molten pool by selective laser melting using a cellular automaton, Mater. Des., 185 (2020) 108230, doi: https://doi.org/10.1016/J.MATDES.2019.108230.

J. Janesch, Two-wire vs. Four-wire Resistance Measurements: Which Configuration Makes Sense for Your Application?, Keithley, USA (2013) 2–4.

Acknowledgments

The research described herein was supported by the National Research Foundation of Korea (NRF) (No. RS-2023-00208039) and by the Innopolis Foundation of Korea (No. 2023-SB-SB-0079) funded by the Ministry of Science and ICT (MSIT, Korea). This research was also supported by the Regional Innovation Strategy (RIS) (2021RIS-004) through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (MOE, Korea). In addition, this work was supported by the Technology Development Program (S3288700, S3275266) funded by the Ministry of SMEs and Startups (MSS, Korea), and by the Korea Institute for Advancement of Technology (KIAT) (P0018009) funded by the Ministry of Trade, Industry, and Energy (MOTIE, Korea). The opinions expressed in this paper are those of the authors and do not necessarily reflect the sponsors’ views.

Author information

Authors and Affiliations

Corresponding author

Additional information

Dongkyoung Lee received his Ph.D. in Mechanical Engineering in 2012 and an M.S. in 2011, both from the University of Michigan, Ann Arbor, MI, U.S.A. He also earned an M.S. in Aerospace Engineering from the same university in 2017, and a B.S. in Mechanical Engineering from Hanyang University, Seoul, South Korea in 2006. Currently, he is an Associate (Tenured) Professor at Kongju National University, South Korea, in the Department of Mechanical and Automotive Engineering, Department of Future Convergence Engineering, and Center for Advanced Materials and Parts of Powder (CAMP2). His research focuses on laser-aided manufacturing, with particular emphasis on applications in lithium-ion batteries, fuel cells, nuclear decommissioning, advanced semiconductor packaging, and display technologies.

Lanh Trinh obtained his M.S. in Engineering from Kongju National University, Cheonan, Korea, in 2021. During his master’s program, his research specialized in laser welding for dissimilar metals in Lithium-ion batteries. Presently, he is pursuing a Ph.D. in Materials Engineering at the University of Nebraska-Lincoln, NE, U.S.A. His current research focuses on advanced manufacturing and fabrication of high entropy materials tailored for extreme environments, encompassing high temperature, corrosion, and irradiation.

Rights and permissions

About this article

Cite this article

Trinh, L., Lee, D. Effect of welding path on the weld quality of aluminum tab and steel battery case in lithium-ion battery. J Mech Sci Technol 38, 2385–2395 (2024). https://doi.org/10.1007/s12206-024-0417-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0417-1