Abstract

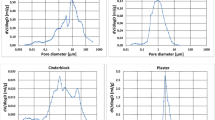

This study proposes a numerical model of the cake-baking process, including its heat and mass transfer processes and the phase change process of water, using the enthalpy-porosity method. The specific heat and thermal conductivity of the cake dough were measured as functions of temperature using a differential scanning calorimeter and the hot plate method with a probe, respectively, for a numerical evaluation of the variations in the thermo-physical properties of the cake dough. The internal and upper-surface temperatures of the cake were measured using thermocouples and an infrared camera, respectively. The mass loss of the cake was measured to determine its water content fraction. The commercial computational fluid dynamics software Fluent 19.2 was used to develop the numerical model of cake baking. The experimental and numerical model results were compared quantitatively and showed excellent agreement. In general, the temperature in the central region of the cake was lower than the internal temperature close to the cake pan. The upper-surface temperatures of the cake exceeded 100 °C and tended to increase toward the cake edge. The water content initially decreased linearly with time. Finally, the correlation between the upper-surface temperature and brightness of the cake dough was examined to determine the cake-baking performance.

Similar content being viewed by others

Abbreviations

- a :

-

Height of center of bread, mm

- a w :

-

Water activity

- b :

-

Radius of bread, mm

- c :

-

Height of end of bread, mm

- D :

-

Water diffusion coefficient, m2/s

- H :

-

Enthalpy, J/kg

- k :

-

Thermal conductivity, W/m-K

- a w :

-

Mass transfer coefficient, kg/Pa-m2-s

- L :

-

Latent heat of water, kJ/kg

- l :

-

Distance between pan and bread, mm

- m :

-

Mass, kg

- P :

-

Pressure, Pa

- a w :

-

Contact resistance, m2-K/W

- T :

-

Temperature, °C

- t :

-

Time, s

- v :

-

Vector

- W :

-

Water content

- β :

-

On/off function

- ρ :

-

Density, kg/m3

- cake :

-

Cake

- s :

-

Solid or surface

- sat :

-

Saturated

- wall :

-

Wall

- water :

-

Water

References

P. Sluimer, Heat Transfer in Dough During the Baking of Bread, Instituut voor Graan, Meel en Brood Mededeling nr, The Netherlands (1987).

U. D. Vries, P. Sluimer and A. H. Bloksma, A Quantitative Model for Heat Transport in Dough and Crumb During Baking, Instituut voor Graan, Meel en Brood Mededeling nr, The Netherlands (1988).

B. Zanoni, S. Pierucci and C. Peri, Study of the bread baking process—II. Mathematical modelling, Journal of Food Engineering, 23(3) (1994) 321–336.

N. Therdthai, W. Zhou and T. Adamczak, Two-dimensional CFD modelling and simulation of an industrial continuous bread baking oven, Journal of Food Engineering, 60(2) (2003) 211–217.

J. Zhang and A. K. Datta, Mathematical modeling of bread baking process, Journal of Food Engineering, 75(1) (2006) 78–89.

A. Mondal and A. K. Datta, Bread baking–a review, Journal of Food Engineering, 86(4) (2008) 465–474.

V. Jury, J. Y. Monteau, J. Comiti and A. Le-Bail, Determination and prediction of thermal conductivity of frozen part baked bread during thawing and baking, Food Research International, 40(7) (2007) 874–882.

M. Sakin, F. Kaymak-Ertekin and C. Ilicali, Simultaneous heat and mass transfer simulation applied to convective oven cup cake baking, Journal of Food Engineering, 83(3) (2007) 463–474.

E. Purlis and V. O. Salvadori, Bread baking as a moving boundary problem, part 1: mathematical modelling, Journal of Food Engineering, 91(3) (2009) 428–433.

N. Chhanwal, A. Anishaparvin, D. Indrani, K. S. M. S. Raghavarao and C. Anandharamakrishnan, Computational fluid dynamics (CFD) modeling of an electrical heating oven for bread-baking process, Journal of Food Engineering, 100(3) (2010) 452–460.

V. Nicolas, P. Glouannec, J. P. Ploteau, P. Salagnac and V. Jury, Experiment and multiphysic simulation of dough baking by convection, infrared radiation and direct conduction, International Journal of Thermal Sciences, 115 (2017) 65–78.

M. Al-Nasser, I. Fayssal and F. Moukalled, Numerical simulation of bread baking in a convection oven, Applied Thermal Engineering, 184 (2021) 116252.

M. Khodeir, O. Rouaud, A. Ogé, V. Jury, P. Le-Bail and A. Le-Bail, Study of continuous cake pre-baking in a rectangular channel using ohmic heating, Innovative Food Science & Emerging Technologies, 67 (2021) 102580.

E. Purlis and V. O. Salvadori, Bread baking as a moving boundary problem, part 2: model validation and numerical simulation, Journal of Food Engineering, 91(3) (2009) 434–442.

V. Nicolas, P. Salagnac, P. Glouannec, J. P. Ploteau, V. Jury and L. Boillereaux, Modelling heat and mass transfer in deformable porous media: application to bread baking, Journal of Food Engineering, 130 (2014) 23–35.

B. Niezgoda-Żelasko, The enthalpy-porosity method applied to the modelling of the ice slurry melting process during tube flow, Procedia Engineering, 157 (2016) 114–121.

G. Havenith, M. G. Richards, X. Wang, P. Brode, V. Candas, R. den Hartog and W. Nocker, Apparent latent heat of evaporation from clothing: attenuation and “heat pipe” effects, Journal of Applied Physiology, 104(1) (2008) 142–149.

N. Hamdami, J. Y. Monteau and A. Le Bail, Heat and mass transfer in par-baked bread during freezing, Food Research International, 37(5) (2004) 477–488.

I. Lind and C. Rask, Sorption isotherms of mixed minced meat, dough, and bread crust, Journal of Food Engineering, 14(4) (1991) 303–315.

E. Purlis and V. O. Salvadori, Modelling the browning of bread during baking, Food Research International, 42(7) (2009) 865–870.

Acknowledgments

This research was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (NRF-2019R1A5A8083201).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Dong Jae Lee received his B.S. degree in 2007, M.S. degree in 2014 and, Ph.D. degree in 2023 from Pusan National University, Korea. Dr. Lee is currently an Engineer at LG Electronics in Changwon. He is developing a wide variety of home appliances like a gas oven range, an airconditioner and a vacuum cleaner. His research interests are focused on combustion, fluid dynamics, and system dynamics.

Gyeong Min Kim received his B.S. degree from Changwon National University, Korea in 2021, M.S. degree from Pusan National University, Korea in 2023. He is currently working on home appliance and air solution product optimization R&D center at LG Electronics. His research interests focus on the computational fluid dynamics.

Man Yeong Ha received his B.S. degree from Pusan National University, Korea in 1981, M.S degree, in 1983, from Korea Advanced Institute of Science and Technology, Korea, and Ph.D. degree from Pennsylvania State University, USA in 1990. Dr. Ha is currently a Professor at the School of Mechanical Engineering at Pusan National University in Busan, Korea. He serves as an Editor of the Journal of Mechanical Science and Technology. His research interests are focused on thermal management, computational fluid dynamics, and micro/nano fluidics.

Rights and permissions

About this article

Cite this article

Lee, D.J., Kim, G.M., Park, S.I. et al. Numerical model of cake baking based on enthalpy–porosity method. J Mech Sci Technol 38, 2081–2089 (2024). https://doi.org/10.1007/s12206-024-0338-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0338-z