Abstract

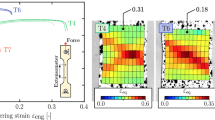

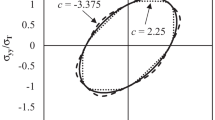

A higher-order asymptotic J-A2C-C solution, which is suitable for studying cylinder structure with a penetrating crack at outside surface, was proposed by investigating the J-A2 two-parameter method. For cylinder structure with different crack sizes at the outside surface, the methods of FEA, HRR theory, the J-A2 theory and the J-A2C-C method were adopted to calculate the opening stress at crack tip, and comparative analysis by using different methods was made in this paper. The influences of different crack sizes and load values on computational accuracy by using the J-A2C-C method were studied. It can be found that the opening stress obtained by the J-A2C-C method can match well with the FEA numerical results, and the J-A2C-C method can be used to study the crack-tip constraint from small-scale yield condition to large-scale yield condition.

Similar content being viewed by others

References

B. N. Nguyen, P. Onck and E. Giessen, Crack-tip constraint effects on creep fracture, Eng. Fract. Mech., 65 (2000) 467–490.

T. V. Pavankumar, J. Chattopadhyay and B. K. Dutta, Numerical investigations of crack-tip constraint parameters in two-dimensional geometries, Int. J. Pres. Ves. Pip., 77 (2000) 345–355.

Y. W. Dai, Y. H. Liu and F. Qin, Constraint modified time dependent failure assessment diagram(TDFAD) based on C(t)-A2(t) theory for creep crack, Int. J. Mech. Sci., 165 (2020) 105193.

S. Cravero and C. Ruggieri, Structural integrity analysis of axially cracked pipelines using conventional and constraint-modified failure assessment diagrams, Int. J. Pres. Ves. Pip., 83 (2006) 607–617.

R. A. Ainsworth, A constraint-based failure assessment diagram for fracture assessment, Int. J. Pres. Ves. Pip., 64 (1995) 277–285.

O. Bouledroua, M. Hadj Meliani and G. Pluvinage, Assessment of pipe defects using a constraint-modified failure assessment diagram, J. Fail. Anal. and Preven., 17 (2017) 144–153.

S. Cravero and C. Ruggieri, Structural integrity analysis of axially cracked pipelines using conventional and constraint-modified failure assessment diagrams, Int. J. Pres. Ves. Pip., 83 (2006) 607–617.

B. G. N. Muthanna, O. Bouledrous and M. Meriem-Benziane, Assessment of corroded API 5L X52 pipe elbow using a modified failure assessment diagram, Int. J. Pres. Ves. Pip., 190 (2021) 104291.

M. L. Williams, On the stress distribution at the base of a stationary crack, J. Appl. Mech., 24 (1) (1957) 109–114.

N. P. O’Dowd and C. F. Shih, Family of crack-tip fields characterized by a triaxiality parameter — I. Structure of fields, J. Mech. Phys. Solids., 39 (1991) 989–1015.

N. P. O’Dowd and C. F. Shih, Family of crack-tip fields characterized by a triaxiality parameter — II. Fracture applications, J. Mech. Phys. Solids., 40 (1992) 939–963.

Y. J. Chao, S. Yang and M. A. Sutton, On the fracture of solids characterized by one or two parameters: theory and practice, J. Mech. Phys. Solids., 42 (1994) 629–647.

X. L. Huang, Roles of in-plane and out-of-plane T-stresses in crack tip plastic zones and fracture toughness under mixed mode I/II loading, Eng. Fract. Mech., 277 (2023) 108990.

N. Deka and K. N. Jonnalagadda, Effect of constraint and latent hardening ratio on the plastic flow around a crack tip in a hardening FCC single crystal, Int. J. Plasticity, 115 (2019) 132–153.

A. E. Oskui, N. Soltani, M. Rajabi and S. Schmauder, Mixed-mode fracture behavior of AM60 magnesium alloy using two parameter fracture mechanics, Eng. Fract. Mech., 218 (2019) 106566.

Y. J. Chao, X. K. Zhu and L. Zhang, Higher-order asymptotic crack-tip fields in a power-law creeping material, Int. J. of Solids and Structures, 38 (2001) 3853–3875.

G. C. Jiao, W. Z. Wang and P. N. Jiang, Crack-tip constraint analysis of two collinear cracks under creep condition, Struct. Eng. and Mech., 43 (3) (2012) 311–320.

S. Yang, Y. J. Chao and M. A. Sutton, Higher order asymptotic fields in a power law hardening material, Eng. Fract. Mech., 45 (1993) 1–20.

Y. J. Chao and X. K. Zhu, J-A2 characterization of crack tip fields: extent of J-A2 dominance and size requirements, Int. J. of Fract., 89 (1998) 285–307.

S. H. Lee, H. W. Jung, Y. J. Kim, K. Nikbin and R. A. Ainsworth, Analysis of 316H creep crack initiation data at 550 °C using a crack tip constraint parameter, Eng. Fract. Mech., 248 (2021) 107746.

W. C. Jiang, Y. Luo and B. Z. Zhang, Characterization of creep constraint effect for brazed joint specimens at crack tip by new constraint parameter As, Theor. Appl. Fract. Mec., 109 (2020) 102707.

Y. J. Chao, X. K. Zhu and Y. Kim, Characterization of crack-tip field and constraint for bending specimens under large-scale yielding, Int. J. of Fract., 127 (2004) 283–302.

X. K. Zhu and Y. J. Chao, Specimens size requirements for two-parameter fracture toughness testing, Int. J. of Fract., 135 (2005) 117–136.

G. C. Jiao, W. Z. Wang and S. J. Tan, Crack-tip constraint analysis of SENB specimen under creep condition, J. of Mech. Sci. and Tech., 29 (2) (2015) 501–506.

G. Shen, W. R. Tyson and A. Glover, Constraint effects on pipeline toughness, Proceedings of the 4thInternational Conference on Pipeline Technology, Ostend, Belgium, 2 (2004) 703–720.

V. G. M. D. Kumar, M. D. German and C. F. Shih, An Engineering Approach for Elastic-Plastic Fracture Analysis, General Electric Co., New York, USA (1981).

Acknowledgments

This research was funded by the National Key Research and Development Program of China (grant number 2021YFC 3090403 and 2021YFC3001904), the Scientific and Technological Program of China National Fire and Rescue Administration (grant number 2021XFZD05).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Wei Shi is an associate research fellow at Shanghai Fire Research Institute of MEM.

Jun-jun Wang is an associate research fellow at Shanghai Fire Research Institute of MEM.

Guang-chen Jiao is a Senior Engineer in Shanghai Hui Ce Information Technology Co., Ltd. His research interest is fracture mechanics.

Chao Liu is an associate research fellow at Shanghai Jiao Tong University.

Rights and permissions

About this article

Cite this article

Shi, W., Wang, Jj., Liu, C. et al. Crack-tip constraint analysis of cylinder structure with axial penetrating crack at outside surface. J Mech Sci Technol 38, 1949–1955 (2024). https://doi.org/10.1007/s12206-024-0327-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0327-2