Abstract

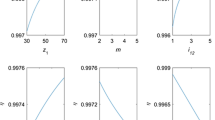

In order to study the influence of various factors on the transmission error of an RV (rotate vector), the working principle and structure of reducer are analyzed, and the ratio is calculated. The mass-spring equivalent model is used to calculate the force, and the mathematical model of transmission error is established and combined with the translation-torsion coupling model. The transmission performance of the RV reducer was characterized using ADAMS and compared with the mathematical model. The effects of three different modification methods and load analysis techniques at different output terminals on the transmission error and frequency ratio are compared. Increasing the meshing clearance between cycloid gear and pin tooth will increase the error. An RV reducer test bench is established to compare the influence of different speeds and torques on transmission error. The analysis shows that the gap between the secondary cycloidal pin gear transmission and the crankshaft installation error is the main cause of the tooth gap. The simulation and experimental results verify the accuracy of the mathematical model.

Similar content being viewed by others

Abbreviations

- m bx :

-

The mass of the cycloidal wheel

- J oj :

-

The moment of inertia of the cycloidal wheel

- m s :

-

The center wheel mass

- A i :

-

The angle between the center wheel and planetary gear meshing line and the X axis

- J s :

-

The moment of inertia of the planetary gear

- R s :

-

The radius of the base circle of the center wheel

- ω c :

-

The theoretical angular velocity of the planet carrier

- J sp :

-

The moment of inertia of the connecting mechanism between the planetary gear and the crankshaft

- m sp :

-

The planetary gear and crankshaft mass

- m ca :

-

The planet carrier mass

- g :

-

The acceleration of gravity

- J ca :

-

The moment of inertia of the planet carrier

- T out :

-

The torque in the opposite direction of the output shaft

References

L. Burgazzi, About time-variant reliability analysis with reference to passive systems assessment, Reliability Engineering and System Safety, 93(11) (2008) 1682–1688.

T. X. Li, M. Tian, H. Xu, X. Z. Deng, X. An and J. X. Su, Meshing contact analysis of cycloidal-pin gear in RV reducer considering the influence of manufacturing error, Journal of the Brazilian Society of Mechanical Sciences and Engineering, 42(3) (2020) 133.

R. Aini, H. Rahnejat and R. Gohar, A five degrees of freedom analysis of vibrations in precision spindles, International Journal of Machine Tools and Manufacture, 30(1) (1990) 1–18.

C. Gorla, P. Davoli, F. Rosa, C. Longoni, F. Chiozzi and A. Samarani, Theoretical and experimental analysis of a cycloidal speed reducer, Journal of Mechanical Design, 130(11) (2008) 1043–1051.

A. D. Pham and H. J. Ahn, Rigid precision reducers for machining industrial robots, International Journal of Precision Engineering and Manufacturing, 22(8) (2021) 1469–1486.

D. C. H. Yang and J. G. Blanche, Design and application guidelines for cycloid drives with machining tolerances, Mechanism and Machine Theory, 25(5) (1990) 487–501.

T. Hidaka, N. Sugimoto and T. Ishida, Effects of errors of elements on load distribution in planetary gears with various load equalizing mechanisms, Transactions of the Japan Society of Mechanical Engineers Series C, 52(480) (1986) 2200–2206.

R. Zhang, J. Zhou and Z. Wei, Study on transmission error and torsional stiffness of RV reducer under wear, Journal of Mechanical Science and Technology, 36 (2022) 4067–4081.

T. X. Li, X. T. An and X. Z. Deng, A new tooth profile modification method of cycloidal gears in precision reducers for robots, Applied Sciences, 10(4) (2020) 1266.

H. Ju, L. Wei and Q. Ze, Lubrication characteristics of cycloidal wheel pin wheel transmission of RV reducer, Journal of Central South University, 28(2) (2021) 398–417.

Y. H. Yang, G. C. Zhou, L. Chang and G. Chen, A modelling approach for kinematic equivalent mechanism and rotational transmission error of RV reducer, Mechanism and Machine Theory, 163 (2021) 104384.

H. Wang, Z. Y. Shi and B. Yu, Transmission performance analysis of RV reducers influenced by profile modification and load, Applied Sciences, 9(19) (2019) 4099.

T. Li, G. Wang, X. Deng, X. An, C. Xing and W. Ma, Contact analysis of cycloidal-pin gear of RV reducer under the influence of profile error, Journal of Physics: Conference Series, 1168 (2019) 2095.

G. Y. Sun, F. X. Zhao and F. Jiang, Backlash analysis of RV reducer based on error factor sensitivity and monte-carlo simulation, International Journal of Hybrid Information Technology, 7(2) (2014) 283–292.

Y. H. Zhang, C. Zhou and W. D. He, Virtual prototype simulation and transmission error analysis for RV reducer, Applied Mechanics and Materials, 789(13) (2015) 226–230.

X. Y. Chu, H. Xu and X. Wu, The method of selective assembly for the RV reducer based on genetic algorithm, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 232(6) (2018) 921–929.

C. F. Hsieh, Traditional versus improved designs for cycloidal speed reducers with a small tooth difference: the effect on dynamics, Mechanism and Machine Theory, 86 (2015) 15–35.

J. J. Gu, D. S. Huang and J. L. Liu, Manufacturing quality assurance for a rotate vector reducer with vibration technology, Journal of Mechanical Science and Technology, 33(5) (2019) 1995–2001.

L. X. Xu, B. K. Chen and C. Y. Li, Dynamic modelling and contact analysis of bearing-cycloid-pinwheel transmission mechanisms used in joint rotate vector reducers, Mechanism and Machine Theory, 137(4) (2019) 432–458.

J. Huang, C. Y. Li and Y. Zhang, Transmission error analysis of cycloidal pinwheel meshing pair based on rolling-sliding contact, Journal of the Brazilian Society of Mechanical Sciences and Engineering, 43(7) (2021) 355.

K. S. Lin, K. Y. Chan and J. J. Lee, Kinematic error analysis and tolerance allocation of cycloidal gear reducers, Mechanism and Machine Theory, 124 (2018) 73–91.

X. Li, B. K. Chen and Y. W. Wang, Mesh stiffness calculation of cycloidal-pin gear pair with tooth profile modification and eccentricity error, Journal of Central South University, 25(7) (2018) 1717–1731.

Z. Feng, H. P. Chen and G. H. Feng, Planetary closed differential motion analysis of RV reducer, Mechanical Transmission, 43(5) (2019) 44–46, 75, DOI:https://doi.org/10.16578/j.issn.1004.2539.2019.05.009.

L. J. Shan, Y. T. Liu and W. D. He, Analysis of nonlinear dynamic accuracy on RV transmission system, Advanced Materials Research, 510 (2012) 529–535.

S. T. Li, Design and strength analysis methods of the trochoidal gear reducers, Mechanism and Machine Theory, 81 (2014) 140–154.

H. L. Wang, J. Li, Y. L. Fu and Z. J. Zhang, Reliability modeling and analysis of cycloid gear grinding machines based on the bootstrap-bayes method, Journal of Advanced Mechanical Design, Systems, and Manufacturing, 17 (13) (2023) DOI: https://doi.org/10.1299/jamdsm.2023jamdsm0033.

H. L. Wang, K. Fang, J. Li and C. F. Xi, Analysis and experimental study on vibration characteristics of the RV reducer, Advances in Mechanical Engineering, 15 (6) (2023) DOI: https://doi.org/10.1177/16878132231181328.

L. X. Xu, J. L. Zhong, Y. Li and L. Chang, Design and dynamic transmission error analysis of a new type of cycloidal-pin reducer with a rotatable output-pin mechanism, Mechanism and Machine Theory, 181(4) (2023) 105218.

T. X. Li, J. X. Zhou and X. Z. Deng, A manufacturing error measurement methodology for a rotary vector reducer cycloidal wheel gear based on a gear measuring center, Measurement Science and Technology, 29(7) (2018) 109–112.

B. K. Chen, C. Y. Peng and J. Huang, A new error model and compensation strategy of angle encoder in torsional characteristic measurement system, Sensors, 19(17) (2019) 3772.

Z. M. Fan, F. Jiang, R. L. Ma, M. K. Wang and J. Xu, Calculation of meshing stiffness of double involute gears based on finite element method, Mechanical and Electrical Engineering Magazine, 38(2) (2021) 151–157.

Z. Liu, T. Zhang and Y. Wang, Experimental studies on torsional stiffness of cycloidal gear based on machining parameters of tooth surfaces, International Journal of Precision Engineering and Manufacturing, 20(6) (2019) 1017–1025.

Acknowledgments

This work was supported in part by the Union Fund of Science and Technology R&D Plan of Henan Province (Grant No. 222103810040), in part by the Key Scientific Research Projects of Higher Education Institutions in Henan Province (Grant No. 23A460017), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Huiliang Wang received the Ph.D. degree in mechanical design and theory from Northwestern Polytechnical University, Xian, Shanxi, China, in 2016. He is currently an Associate Professor with the School of Mechatronics Engineering, Henan University of Science and Technology, Luoyang, China. His research interests include industrial engineering, mechanical product digital design and performance analysis, and computer integrated manufacturing systems.

Wenhua Fu received a bachelor’s degree from Xinlian College of Henan Normal University. Now she is studying in mechanical engineering in Henan University of Science and Technology. Her research focuses on grinding internal helical gears.

Kai Fang received a bachelor’s degree in mechanics from Shangqiu Institute of Technology. He is currently studying for a master’s degree in mechanical engineering at Henan University of Science and Technology. His research directions include reducer design and analysis, mechanical dynamics analysis and so on.

TianCong Chen received a master’s degree in mechanical and electronic engineering from Henan University of Science and Technology. She is currently a lecturer at Henan Mechanical and Electrical Vocational College. Her main research interests are research on key technologies of rehabilitation robot, mechatronics system.

Rights and permissions

About this article

Cite this article

Wang, H., Fu, W., Fang, K. et al. Transmission characteristics of an RV reducer based on ADAMS. J Mech Sci Technol 38, 787–802 (2024). https://doi.org/10.1007/s12206-024-0126-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0126-9