Abstract

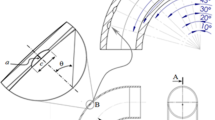

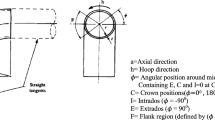

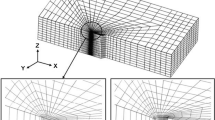

In the present study, the X-FEM technique was used to perform this work, taking into consideration the operating service state of the elbow steel. Semi-elliptical defects were created on the internal surface of the extrados section of elbow. Combined pressure, temperature, and bending loads were applied in the numerical investigation. The damage was depicted in moment-rotation curves and was described as a consequence of several simultaneous factors. The obtained results were in agreement with the literature, which proved that the elbow becomes more brittle at low temperature with less capacity of bearing.

Similar content being viewed by others

Abbreviations

- M :

-

Collapse moment

- M*:

-

Instability moment

- r :

-

Rotation at collapse

- r*:

-

Rotation at instability

- T :

-

Temperature

References

H. M. Tawancy, L. M. Al-Hadhrami and F. K. Al-Yousef, Analysis of corroded elbow section of carbon steel piping system of an oil-gas separator vessel, Case Studies in Engineering Failure Analysis, 1(1) (2013) 6–14, https://doi.org/10.1016/j.csefa.2012.11.001.

M. N. Ilman, Analysis of internal corrosion in subsea oil pipeline, Case Studies in Engineering Failure Analysis, 2(1) (2014) 1–8, https://doi.org/10.1016/j.csefa.2013.12.003.

M. M. Shahzamanian, M. Kainat, N. Yoosef-Ghodsi and S. Adeeb, Systematic literature review of the application of extended finite element method in failure prediction of pipelines, Journal of Pipeline Science and Engineering, 1(2) (2021) 241–251, https://doi.org/10.1016/j.jpse.2021.02.003.

N. Jones and R. S. Birch, Influence of internal pressure on the impact behavior of steel pipelines, Journal Pressure Vessel Technol, 118(4) (1996) 464–471, https://doi.org/10.1115/1.2842215.

H. M. Shalaby, W. T. Riad, A. A. Alhazza and M. H. Behbehani, Failure analysis of ruptured pipe connected to natural gas pre-heater, Engineering Failure Analysis, 13(5) (2006) 797–804, https://doi.org/10.1016/j.engfailanal.2005.02.005.

M. Soudani, M. H. Meliani, K. El-Miloudi, Z. Azari, A. A. Sorour, N. Merah and G. Pluvinage, Reduction of hydrogen embrittlement of API 5l X65 steel pipe using a green inhibitor, International Journal of Hydrogen Energy, 43(24) (2018) 11150–11159, https://doi.org/10.1016/j.ijhydene.2018.04.236.

C. Zou, P. Zhao, M. Wang, D. Liu, H. Wang and Z. Wen, Failure analysis and faults diagnosis of molecular sieve in natural gas dehydration, Engineering Failure Analysis, 34 (2013) 115–120, https://doi.org/10.1016/j.engfailanal.2013.07.031.

M. C. Zhao, B. Tang, Y. Y. Shan and K. Yang, Role of microstructure on sulfide stress cracking of oil and gas pipeline steels, Metallurgical and Materials Transactions A, 34 (2003) 1089–1096, https://doi.org/10.1007/s11661-003-0128-7.

H. F. Lopez, R. Raghunath, J. L. Albarran and L. Martinez, Microstructural aspects of sulfide stress cracking in an API X-80 pipeline steel, Metallurgical and Materials Transactions A, 27(11) (1996) 3601–3611, https://doi.org/10.1007/BF02595451.

A. Belalia, A. Rahmani, G. B. Lenkey, G. Pluvinage and Z. Azari, Dynamic characterization of API 5L X52 pipeline steel, Key Engineering Materials, 498 (2012) 15–30, https://doi.org/10.4028/www.scientific.net/KEM.498.15.

L. Shi, C. Wang and C. Zou, Corrosion failure analysis of L485 natural gas pipeline in CO2 environment, Engineering Failure Analysis, 36 (2014) 372–378, https://doi.org/10.1016/j.engfailanal.2013.11.009.

M. Meriem-Benziane, B. Bou-Saïd and N. Boudouani, The effect of crude oil in the pipeline corrosion by the naphthenic acid and the sulfur: A numerical approach, Journal of Petroleum Science and Engineering, 158 (2017) 672–679, https://doi.org/10.1016/j.petrol.2017.08.073.

M. R. Amara, O. Bouledroua, M. H. Meliani, B. G. N. Muthanna, M. T. Abbess and G. Pluvinage, Assessment of PIPE for CO2 transportation using a constraint modified CTOD failure assessment diagram, Structural Integrity and Life, 18(2) (2018) 149–153.

M. Hayes, Algerian gas to Europe: the transmed pipeline and early spanish gas import projects; geopolitics of gas working paper series, James A. Baker III Institute for Public Policy Energy Forum, Houston, TX, USA (2004).

S. Lochner and C. Dieckhöner, Civil unrest in North Africa—risks for natural gas supply, Energy Policy, 45 (2012) 167–175, https://doi.org/10.1016/j.enpol.2012.02.009.

F. Holz, P. M. Richter and R. Egging, A global perspective on the future of natural gas, Review of Environmental Economics and Policy, 9 (1) (2015).

D. Lawson, Advanced Pipeline Designs to Increase Hydrocarbon Flow, Emerson, USA (2016).

B. G. N. Muthanna, O. Bouledroua, M. Meriem-Benziane, M. Hadj-Meliani, G. Pluvinage and R. K. Suleiman, Numerical study of semi-elliptical cracks in the critical position of pipe elbow, Frattura ed Integrità Strutturale, 13(49) (2019) 463–477, https://doi.org/10.3221/IGF-ESIS.49.44.

B. G. N. Muthanna, O. Bouledroua, M. Meriem-Benziane, M. R. Setvati and M. B. Djukic, Assessment of corroded API 5L X52 pipe elbow using a modified failure assessment diagram, International Journal of Pressure Vessels and Piping, 190 (2021) 104291, https://doi.org/10.1016/j.ijpvp.2020.104291.

B. C. Mondal, A. S. Dhar and H. I. Hafiz, Burst pressure assessment of pipe bend/elbow for transmission pipelines, Thin-Walled Structures, 174 (2022) 109148, https://doi.org/10.1016/j.tws.2022.109148.

M. Gourma and P. G. Verdin, Nature and magnitude of operating forces in a horizontal bend conveying gas-liquid slug flows, Journal of Petroleum Science and Engineering, 190 (2020) 107062, https://doi.org/10.1016/j.petrol.2020.107062.

M. Amara, B. G. N. Muthanna, M. T. Abbes and M. H. Meliani, Effect of sand particles on the erosion-corrosion for a different locations of carbon steel pipe elbow, Procedia Structural Integrity, 13 (2018) 2137–2142, https://doi.org/10.1016/j.prostr.2018.12.151.

B. G. N. Muthanna, M. Amara, M. H. Meliani, B. Mettai, Z. Bozic, R. Suleiman and A. A. Sorour, Inspection of internal erosion-corrosion of elbow pipe in the desalination station, Engineering Failure Analysis, 102 (2019) 293–302, https://doi.org/10.1016/j.engfailanal.2019.04.062.

H. Boukortt, M. Amara, M. H. Meliani, O. Bouledroua, B. G. N. Muthanna, R. K. Suleiman, A. A. Sorour and G. Pluvinage, Hydrogen embrittlement effect on the structural integrity of API 5L X52 steel pipeline, International Journal of Hydrogen Energy, 43(42) (2018) 19615–19624, https://doi.org/10.1016/j.ijhydene.2018.08.149.

M. Wasim and M. B. Djukic, Hydrogen embrittlement of low carbon structural steel at macro-, micro-and nano-levels, International Journal of Hydrogen Energy, 45(3) (2020) 2145–2156, https://doi.org/10.1016/j.ijhydene.2019.11.070.

M. Soudani, O. Bouledroua, M. Hadj Meliani, K. El-Miloudi, B. G. N. Muthanna, A. Khelil and G. Pluvinage, Corrosion inspection and recommendation on the internal wall degradation caused rupture of 6″ gas line pipe, Journal of Bio-and Tribo-Corrosion, 4 (2018) 1–6, https://doi.org/10.1007/s40735-018-0145-0.

T. Kelil, M. Amara, M. H. Meliani, B. G. N. Muthanna, Ž. Božić, R. Suleiman and G. Pluvinage, Assessment of API X65 steel pipe puffiness by a strain based design (SBD) approach under bi-axial loading, Engineering Failure Analysis, 104 (2019) 578–588, https://doi.org/10.1016/j.engfailanal.2019.06.063.

M. Meriem-Benziane, B. Bou-Said, B. G. N. Muthanna and I. Boudissa, Numerical study of elbow corrosion in the presence of sodium chloride, calcium chloride, naphthenic acids, and sulfur in crude oil, Journal of Petroleum Science and Engineering, 198 (2021) 108124, https://doi.org/10.1016/j.petrol.2020.108124.

I. J. Kim, Y. C. Jang, Y. Y. Jang, J. H. Moon and N. S. Huh, Estimation of tensile strain capacity for thin-walled API X70 pipeline with corrosion defects using the fracture strain criteria, Journal of Mechanical Science and Technology, 34 (2020) 2801–2812, https://doi.org/10.1007/s12206-020-0613-6.

F. Lachaud and I. Michel, Etude de l’endommagement de matériaux composites carbones à matrice thermodurcissable et thermoplastique, Mécanique Industrielle Et Matériaux, 50(2) (1997) 52–57.

E. Abdelouahed, M. Mokhtari and H. Benzaama, Finite element analysis of the thermo-mechanical behavior of composite pipe elbows under bending and pressure loading, Frattura ed Integrità Strutturale, 13(49) (2019) 698–713, DOI https://doi.org/10.3221/IGF-ESIS.49.63.

M. A. Shalaby and M. Y. A. Younan, Effect of internal pressure on elastic-plastic behavior of pipe elbows under in-plane bending moments, J. Pressure Vessel Technol, 121(4) (1999) 400–405, https://doi.org/10.1115/L2883722.

S. Bao, Y. Liu, J. Mao, R. Ge and X. Li, Numerical and experimental investigation on limit load of elbow with local thinning area, International Journal of Pressure Vessels and Piping, 172 (2019) 414–422, https://doi.org/10.1016/j.ijpvp.2019.04.014.

S. A. Karamanos, E. Giakoumatos and A. M. Gresnigt, Nonlinear response and failure of steel elbows under in-plane bending and pressure, J. Pressure Vessel Technol., 125(4) (2003) 393–402, https://doi.org/10.1115/L1613949.

Q. Wang and W. Zhou, Burst capacity analysis of thin-walled pipe elbows under combined internal pressure and bending momen, International Journal of Pressure Vessels and Piping, 194 (2021) 104562, https://doi.org/10.1016/j.ijpvp.2021.104562.

Z. Velazquez, E. Guzman and A. Contreras, Stress corrosion cracking behavior of X60 pipe steel in soil environment, MRS Online Proceedings Library (OPL), 1242 (2009) S4–P131, DOI: https://doi.org/10.1557/PROC-1242-S4-P131.

X. Ren, H. O. Nordhagen, Z. Zhang and O. M. Akselsen, Tensile properties of 420 MPa steel at low temperature, The Twenty-fifth International Ocean and Polar Engineering Conference, Kona, Hawaii, USA (2015) 21–26.

M. A. Mohtadi-Bonab, Effect of different parameters on hydrogen affected fatigue failure in pipeline steels, Engineering Failure Analysis, 137 (2022) 106262, https://doi.org/10.1016/j.eng-failanal.2022.106262.

X. Chen, X. Wang and X. Chen, Efects of temperature on the ratcheting behavior of pressurized 90° elbow pipe under force controlled cyclic loading, Smart Structures and Systems, 19 (2017) 473–485, https://doi.org/10.12989/sss.2017.19.5.473.

S. J. Zakavi and Y. Aghaei, The ratcheting behavior of carbon steel piping elbows under cyclic bending moment and temperature, Journal of the Brazilian Society of Mechanical Sciences and Engineering, 42 (2020) 436, https://doi.org/10.1007/s40430-020-02521-0.

T. P. Fries and T. Belytschko, The extended/generalized finite element method: an overview of the method and its applications, International Journal for Numerical Methods in Engineering, 84(3) (2010) 253–304, https://doi.org/10.1002/nme.2914.

J. M. Melenk and I. Babuska, The partition of unity finite element method: basic theory and applications, Computer Methods in Applied Mechanics and Engineering, 139(1–4) (1996) 289–314, https://doi.org/10.1016/S0045-7825(96)01087-0.

N. Moës, J. Dolbow and T. Belytschko, A finite element method for crack growth without remeshing, International Journal for Numerical Methods in Engineering, 46(1) (1999) 131–150, https://doi.org/10.1002.

Dassault Syst. Simulia Corp., Abaqus V. 6.14 Documentation, Dassault Syst. Simulia Corp., 651 (2014) 2–6.

Z. Zhang, J. Xu, B. Nyhus and E. 0stby, SENT (single edge notch tension) methodology for pipeline applications, Proc., 18th European Conf. on Fracture, Dresden, Germany (2010).

A. Okodi, M. Lin, N. Yoosef-Ghodsi, M. Kainat, S. Hassanien and S. Adeeb, Crack propagation and burst pressure of longitudinally cracked pipelines using extended finite element method, International Journal of Pressure Vessels and Piping, 184 (2020) 104115, https://doi.org/10.1016/j.ijpvp.2020.104115.

J. Jing, F. Gao, J. Johnson, F. Z. Liang, R. L. Williams and J. Qu, Simulation of dynamic fracture along solder-pad interfaces using a cohesive zone model, Proceedings of the ASME 2008 International Mechanical Engineering Congress and Exposition. Volume 6: Electronics and Photonics, Boston, Massachusetts, USA (2008) 171 -176, https://doi.org/10.1115/IMECE2008-68891.

O. V. Trifonov, Numerical stress-strain analysis of buried steel pipelines crossing active strike-slip faults with an emphasis on fault modeling aspects, Journal of Pipeline Systems Engineering and Practice, 6(1) (2015) 04014008, https://doi.org/10.1061/(ASCE)PS.1949-1204.0000177.

N. Hammadi, M. Mokhtari, H. Benzaama, K. Madani, A. Brakna and E. Abdelouahed, Using XFEM to predict the damage with temperature of the steel pipe elbows under bending and pressure loading, Frattura ed Integrità Strutturale, 15(55) (2021) 345–359, DOI https://doi.org/10.3221/IGF-ESIS.55.27.

R. Alipour, R. Alipour, S. S. Rahimian Koloor, M. Petrů and S. A. Ghazanfari, On the performance of small-scale horizontal axis tidal current turbines, part 1: one single turbine, Sustainability, 12(15) (2020) 5985, https://doi.org/10.3390/su12155985.

R. Alipour, R. Alipour, F. Fardian and M. H. Tahan, Optimum performance of a horizontal axis tidal current turbine: A numerical parametric study and experimental validation, Energy Conversion and Management, 258 (2022) 115533, https://doi.org/10.1016/j.enconman.2022.115533.

G. H. Lee, J. K. Seo and J. K. Paik, Condition assessment of damaged elbow in subsea pipelines, Ships and Offshore Structures, 12(1) (2017) 135–151, https://doi.org/10.1080/17445302.2015.1116245.

H. K. Sung, D. H. Lee, S. Y. Shin, S. Lee, Y. Ro, C. S. Lee and B. Hwang, Effects of finish cooling temperature on tensile properties after thermal aging of strain-based API X60 linepipe steels, Metallurgical and Materials Transactions A, 46 (2015) 3989–3998, https://doi.org/10.1007/s11661-015-2984-3.

O. M. Akselsen, E. 0stby and B. Nyhus, Low temperature fracture toughness of X80 girth welds, The Twenty-second International Offshore and Polar Engineering Conference, Rhodes, Greece (2012).

H. Tubex, K. Van Minnebruggen and W. De Waele, Low temperature tensile properties of line pipe steels, Sustainable Construction and Design, 6 (3) (2015).

A. Ahmed-Bensoltane, M. Mokhtari, H. Benzaama, K. Samet, H. Benrouba and E. Abdelouahed, Using XFEM technique to predict the effect of default on the damage of steel pipe reduced-connection under bending and pressure loading, International Journal of Steel Structures, 23(1) (2023) 316–330, https://doi.org/10.1007/s13296-022-00697-w.

Author information

Authors and Affiliations

Corresponding author

Additional information

Chaaben Arroussi is Ph.D. student in Mechanical Engineering, Faculty of Technology, Haasiba Ben Bouali University of Chief, Algeria. His research interests include Mechanical structure, Finite Element Method (FEM), Damage Mechanics.

Rights and permissions

About this article

Cite this article

Arroussi, C., Belalia, A. & Meliani, M.H. Temperature effects on the resistance capacity of API X60 pipe elbow under bending moment using X-FEM method. J Mech Sci Technol 38, 661–669 (2024). https://doi.org/10.1007/s12206-024-0114-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0114-0