Abstract

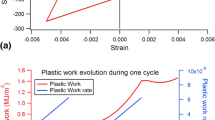

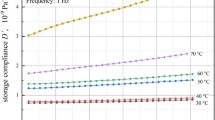

The conventional approach to temperature evolution in cyclic loading is explained by a hysteresis curve with three phases. However, it has not been matched with experimental data except in the beginning of the cyclic loading. Thus, this study suggests a new approach to temperature evolution with three phases in cyclic loading by plastic deformation using the thermoelastic effect. The sample was fabricated following ASTM D638 standard for cyclic loading, and the temperature was measured during the cyclic loading by an infrared camera. Thermography was used to observe partial heating caused by cracks. The results were evaluated with the correlation (R2) coefficient between temperature and the derived equation as 0.96 in phases 1 and 2. Also, the partial heating was observed showing the effect of cracks for the temperature evolution in phases 2 and 3. Based on these results, a new approach to temperature evolution in cyclic loading is suggested.

Similar content being viewed by others

Abbreviations

- V 0 :

-

Original volume

- Δ V :

-

Volume change

- x 0 :

-

Initial length in x - direction

- y 0 :

-

Initial length in y - direction

- z 0 :

-

Initial length in z - direction

- ε x :

-

Strain in x - direction

- ε y :

-

Strain in y - direction

- ε z :

-

Strain in z - direction

- v :

-

Poisson’s ratio

- Δ T :

-

Temperature change

- T 0 :

-

Initial temperature

- α :

-

Coefficient of thermal expansion

- ρ :

-

Density

- c p :

-

Heat capacity

- K :

-

Thermoelastic parameter

- A 0 :

-

Initial cross-sectional area

- ε plastic :

-

Plastic strain caused by viscoelasticity

- σ :

-

Stress

- dT f :

-

Temperature change due to heat conduction

References

W. S. Farren and G. I. Taylor, The heat developed during plastic extension of metals, Proceedings of the Royal Society A, 107(743) (1925) 422–451.

J. A. Charles, F. J. Appl and J. E. Francis, Thermographic determination of fatigue damage, J. of Engineering Materials and Technology, 100(2) (1978) 200–203.

L. Jiang et al., Characterization of the temperature evolution during high-cycle fatigue of the ULTIMET superalloy: experiment and theoretical modeling, Metallurgical and Materials Transactions A, 32 (2001) 2279–2296.

J. Schijve, Significance of Fatigue Cracks in Micro-Range and Macro-Range, in Fatigue Crack Propagation, ASTM International (1967).

P. J. E. Forsyth, The Physical Basis of Metal Fatigue, Blackie and Son, LTD., London (1969).

D.-G. Shang, W.-X. Yao and D.-J. Wang, A new approach to the determination of fatigue crack initiation size, Int. J Fatigue, 20(9) (1998) 683–687.

W. Cui, A state-of-the-art review on fatigue life prediction methods for metal structures, J. Mar. Sci. Technol., 7 (2002) 43–56.

G. Fargione et al., Rapid determination of the fatigue curve by the thermographic method, Int. J Fatigue, 24(1) (2002) 11–19.

G. La Rosa and A. Risitano, Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components, Int. J Fatigue, 22(1) (2000) 65–73.

M. Amiri and M. M. Khonsari, Rapid determination of fatigue failure based on temperature evolution: fully reversed bending load, Int. J Fatigue, 32(2) (2010) 382–389.

L. Zhang et al., Rapid determination of fatigue life based on temperature evolution, Int. J Fatigue, 54 (2013) 1–6.

M. Amiri and M. M. Khonsari, Life prediction of metals undergoing fatigue load based on temperature evolution, Materials Science and Engineering: A, 527(6) (2010) 1555–1559.

J. Montesano, Z. Fawaz and H. Bougherara, Use of infrared thermography to investigate the fatigue behavior of a carbon fiber rein-forced polymer composite, Compos. Struct., 97 (2013) 76–83.

J. W. Holmes and S. F. Shuler, Temperature rise during fatigue of fibre-reinforced ceramics, J. Materials Science Letters, 9 (1990) 1290–1291.

B. Yang et al., Thermographic investigation of the fatigue behavior of reactor pressure vessel steels, Materials Science and Engineering: A, 314(1–2) (2001) 131–139.

J. Gough, Memoirs of the Literary and Philosophical Society of Manchester, Second Series, Manchester Literary and Philosophical Society (1805) 1–288.

W. Thomson (Lord Kelvin), Math. and phys. papers, Quarterly J. Math., 1(291) (1855) 309–310.

J. P. Joule, V. On some thermo-dynamic properties of solids, Philos Trans R Soc Lond, 149 (1859) 91–131.

S. L. Dart, R. L. Anthony and E. Guth, Rise of temperature on fast stretching of synthetics and natural rubbers, Ind. Eng. Chem, 34(11) (1942) 1340–1342.

R. H. Gerke, Thermodynamics of stressed vulcanized rubber, Ind. Eng. Chem., 22(1) (1930) 73–77.

E. Guth, The physics of rubber I. Its observed elastic and thermoelastic behavior, J Appl. Phys., 10(3) (1939) 161–171.

A. K. Wong, S. A. Dunn and J. G. Sparrow, Residual stress measurement by means of the thermoelastic effect, Nature, 332(6165) (1988) 613–615.

M. Nofar et al., Interfacial and rheological properties of PLA/PBAT and PLA/PBSA blends and their morphological stability under shear flow, J. of Rheology, 59(2) (2015) 317–333.

ASTM D638-14, Standard Test Method for Tensile Properties of Plastics, ASTM International (2014).

A. Risitano and G. Risitano, Cumulative damage evaluation in multiple cycle fatigue tests taking into account energy parameters, Int. J Fatigue, 48 (2013) 214–222.

A. Risitano and G. Risitano, Cumulative damage evaluation of steel using infrared thermography, Theoretical and Applied Fracture Mechanics, 54(2) (2010) 82–90.

R. T. L. Ferreira et al., Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers, Composites Part B: Engineering, 124 (2017) 88–100.

B. J. Goodno and J. M. Gere, Mechanics of Materials, Cengage Learning, USA (2020).

R. Hooke, Lectures De Potentia Restitutiva, or, of Spring Explaining the Power of Springing Bodies to Which are Added from Collections, Printed for John Martyn Printer to the Royal Society, London (1678).

A. K. Wong, R. Jones and J. G. Sparrow, Thermoelastic constant or thermoelastic parameter?, J. of Physics and Chemistry of Solids, 48(8) (1987) 749–753.

Acknowledgments

This work was supported by the Korea Institute for Advancement of Technology (KIAT) grant funded by the Korean government (MOTIE) (P0008458, HRD Program for Industrial Innovation), and also supported by Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government (MOTIE) (20222020800130, Development and demonstration of hybrid power system using ORC(Organic Rankine Cycle) and TEG(Thermoelectric Generator) for low and medium temperature industrial waste heat recovery).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Sanglok Park is a failure analysis R&D Engineer at Intel, Chandler, Arizona, United States. He received his M.E. and M.S. in Mechanical Engineering and Electronics Engineering from Inha University and Norfolk State University. His research interests include failure analysis, AI, CFD, and electrical-thermomechanical engineering.

Rights and permissions

About this article

Cite this article

Park, S., Shim, HS., Lee, JS. et al. Analysis of the temperature evolution in cyclic loading using the thermoelastic effect with plastic deformation. J Mech Sci Technol 38, 221–228 (2024). https://doi.org/10.1007/s12206-023-1219-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-1219-6