Abstract

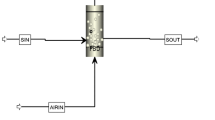

Airflow velocity uniformity in material drying room used in steam blanching and hot-air vacuum drying equipment is crucial for obtaining a good drying quality of fruits and vegetables. To analyze the airflow velocity uniformity and give the optimization design for improving the airflow uniformity, CFD method is used for the flow field analysis of material drying room and the velocity non-uniformity coefficient is used as the evaluation indicator for the velocity uniformity. Results show that the airflow velocity distribution in the material drying room at the original inlet airflow distribution chamber is relatively uneven and the airflow velocity non-uniformity coefficient in drying area is 34 %. For reducing the airflow velocity non-uniformity, the airflow velocity distribution of three structural modification directions with 12 designs in total are analyzed and compared. The minimum airflow velocity non-uniformity coefficient for adding a spoiler model, reducing the closed end width and adding nozzle baffles are 17.1 %, 30.2 %, 10.4 %, respectively. Through comparison, adding the nozzle baffle with a width of 11 mm at the rear end of each nozzle outlet is considered as the optimal designs to conduct the experimental validation. Experimental validation results shows the the relative error between the simulated value and the measured value is within 10 %, proving that the CFD prediction results is reliable and the research results can give a theoretical reference for the designers to evaluate and optimize the structure of inlet airflow distribution chamber for improving the airflow uniformity in drying area.

Similar content being viewed by others

Abbreviations

- Si :

-

Source term in the i direction

- |v|:

-

Velocity magnitude, m/s

- v i :

-

Velocity magnitude in the i direction, m/s

- C 0, C 1 :

-

Empirical coefficients

- M :

-

Non-uniformity coefficient

- σ v :

-

Standard deviation of airflow velocity

- \({\bar v}\) :

-

Average airflow velocity, m/s

- n :

-

Number of monitoring points

- I :

-

Turbulent intensity

- D H :

-

Hydraulic diameter

- C u :

-

Christensen uniformity coefficient

- Hi :

-

Average moisture content in drying area i

- \(\overline H \) :

-

Average moisture content of all areas

- m :

-

Number of drying areas

References

B. Dereje and S. Abera, Effect of some pretreatments before drying on microbial load and sensory acceptability of dried mango slices during storage periods, Cogent Food and Agriculture, 6 (1) (2020) 1807225.

A. K. Babu et al., Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models, Renewable and Sustainable Energy Reviews, 90 (2018) 536–556.

Y. Bie et al., Experimental study on improving the drying uniformity in hot air cross-flow dryer, IOP Conference Series: Earth and Environmental Science, 93 (1) (2017) 012001.

S. R. S. Dev and V. G. S. Raghavan, Advancements in drying techniques for food, fiber, and fuel, Drying Technology, 30 (11) (2012) 1147–1159.

P. Demissie et al., Design, development and CFD modeling of indirect solar food dryer, Energy Procedia, 158 (2019) 1128–1134.

H. Darabi et al., Design a cabinet dryer with two geometric configurations using CFD, Journal of Food Science and Technology, 52 (1) (2015) 359–366.

H. M. Yu et al., Simulation analysis of flow field uniformity in air distribution room of rice seedbed microwave hot air coupling dryer, Journal of Agricultural Mechanization Research, 42 (2) (2020) 15–21.

S. Misha et al., Review on the application of a tray dryer system for agricultural products, World Applied Sciences Journal, 22 (3) (2013) 424–433.

J. Y. Moon et al., Numerical study on flow and heat transfer characteristics of air-jet cooling system, Journal of Mechanical Science and Technology, 32 (12) (2018) 6021–6027.

H. W. Xiao et al., The application of superheated steam impingement blanching (SSIB) in agricultural products processing-A review, Journal of Food Engineering, 132 (2014) 39–47.

M. Böhner et al., Improving the airflow distribution in a multi-belt conveyor dryer for spice plants by modifications based on computational fluid dynamics, Biosystems Engineering, 115 (3) (2013) 339–345.

L. B. Tan and Y. J. Yuan, Numerical simulation on flow field characteristics of the four cylinder engine cooling system and its performance improvement, Journal of Mechanical Science and Technology, 37 (1) (2023) 487–500.

D. K. Sun et al., Optimization of impedance boundary-controlled casing treatment on subsonic compressors, Journal of Mechanical Science and Technology, 37 (5) (2023) 2161–2169.

M. Y. Zhang, Fluid Mechanics, Higher Education Press, Beijing (2010) 439–440.

Y. J. Yuan et al., Numerical and experimental study on drying shrinkage-deformation of apple slices during process of heat-mass transfer, International Journal of Thermal Sciences, 136 (2019) 539–548.

Y. J. Yuan et al., Multiscale and multilayer structural modeling and simulation on drying of grain packing porous media, Drying Technology, 34 (14) (2016) 1664–1676.

Y. Amanlou and A. Zomorodian, Applying CFD for designing a new fruit cabinet dryer, Journal of Food Engineering, 101 (1) (2010) 8–15.

L. B. Tan et al., Flow field analysis and structure improvement of generator unit based on STAR-CCM+, Journal of Xihua University (Natural Science Edition), 42 (1) (2023) 100–105.

L. B. Tan et al., Numerical simulation on fluid flow and temperature prediction of motorcycles based on CFD, Alexandria Engineering Journal, 61 (12) (2022) 12943–12963.

F. Han, H. Guo and X. F. Ding, Design and optimization of a liquid cooled heat sink for a motor inverter in electric vehicles, Applied Energy, 291 (2021) 116819.

J. Q. E et al., Effect analysis on flow and boiling heat transfer performance of cooling water-jacket of bearing in the gasoline engine turbocharger, Applied Thermal Engineering, 130 (2018) 754–766.

Y. Amanlou and A. Zomorodian, Evaluation of air flow resistance across a green fig. bed for selecting an appropriate pressure drop prediction equation, Food and Bioproducts Processing, 89 (2) (2011) 157–163.

J. W. Dai et al., Numerical simulation and optimum design on airflow distribution chamber of air-impingement jet dryer, Transactions of the Chinese Society of Agricultural Engineering, 29 (3) (2013) 69–76.

S. T. Tian and Z. J. Gao, Improved design of airflow distribution chamber in air-impingement oven based on fluent, Modern Food Science and Technology, 25 (6) (2009) 612–616.

M. Qian et al., Structural effects of air duct with square nozzle on performance of heat setting machine, Journal of Engineering Thermophysics, 39 (12) (2018) 2670–2676.

J. S. Li et al., Field evaluation of drip fertigation uniformity effects on distributions of water and nitrate in soil, Transactions of the Chinese Society of Agricultural Engineering, 26 (12) (2010) 27–33.

Acknowledgments

This work was funded by Research and Application Demonstration of Key Technologies in Edible Fungus Industry such as Auricularia auricula-judae (Grants No. 2021YFD1600403), Shaanxi University of Science and Technology Doctoral Research Startup Fund (Grants No.BJ16-19), Shaanxi Provincial Department of Education Youth Innovation Team Research Program Project (Grants No.21JP016), Key Projects of Shaanxi International Science and Technology Cooperation Plan (Grants No.2020KWZ-015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Dong Wang is a Ph.D. and the Master’s supervisor in the College of Mechanical and Electrical Engineering at Shaanxi University of Science and Technology, Shaanxi Province. He is specialized in CFD simulations and doing his research in the field of food drying, modern processing technology and intelligent equipment design of agricultural products.

Libin Tan is a Ph.D. candidate in the College of Mechanical and Electrical Engineering at Shaanxi University of Science and Technology, Shaanxi Province. He is specialized in CFD simulations and doing his research in the field of heat transfer and thermal engineering in industrial applications, heat and mass transfer in food drying process and processing technology.

Yuejin Yuan is a Professor in the College of Mechanical and Electrical Engineering at Shaanxi University of Science and Technology, Shaanxi Province. He received his Ph.D. degree in China Agricultural University. He is specialized in CFD and doing research on heat transfer and thermal engineering in the field of engineering, food drying, and biomass burning.

Yuming Lu is a Master graduated form College of Mechanical and Electrical Engineering at Shaanxi University of Science and Technology, Shaanxi Province. He is specialized in CFD simulations and doing his research in the field of heat and mass transfer in food drying and the usage of modern processing technology.

Rights and permissions

About this article

Cite this article

Wang, D., Tan, L., Yuan, Y. et al. CFD simulation and optimization on airflow uniformity of material drying room used in steam blanching and hot-air vacuum drying equipment. J Mech Sci Technol 37, 5463–5474 (2023). https://doi.org/10.1007/s12206-023-0945-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0945-0