Abstract

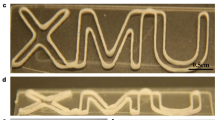

The melt electrowriting (MEW) has broad applications in regenerative medicine and micro-nano electronics. It is an efficient micro-nano scale additive manufacturing technology; however, the fiber jet lag effect of MEW limits the deposition precision and resolution of fiber shape. In this study, the principle of the jet lag effect is studied to overcome the defect of printed structure distortion and improve the ability to print complex structures. A mathematical model of trailing fiber trajectory is established. The study covers jet lag and liquid rope coiling analysis at different speeds. A strategy is adopted by introducing a buffer zone at the corner of the printing structure. The printing path is subdivided and optimized to suppress the influence of jet lag. The results show that the deposited fibers' corner radius is around 63.81±5.66 ìm, which is significantly smaller than that of unoptimized groups. Finally, by utilizing the improved printing paths, the high-precision and complex structures are printed, which demonstrates the feasibility of optimizing the buffer zone for the MEW.

Similar content being viewed by others

References

Y. Huang, X. Wang, Y. Duan, N. Bu and Z. Yin, Controllable self-organization of colloid microarrays based on finite length effects of electrospun ribbons, Soft Matter, 8 (2012) 8302–8311.

A. Hrynevich, I. Liashenko and P. D. Dalton, Accurate prediction of melt electrowritten laydown patterns from simple geometrical considerations, Advanced Materials Technologies, 5 (2020) 2000772.

D. Sun, C. Chang, S. Li and L. Lin, Near-field electrospinning, Nano Letters, 6 (2006) 839–842.

P. Mieszczanek, T. M. Robinson, P. D. Dalton and D. W. Hutmacher, Convergence of machine vision and melt electrowriting, Advanced Materials, 33 (2021) 2100519.

Y. Huang, N. Bu, Y. Duan, Y. Pan, H. Liu, Z. Yin and Y. Xiong, Electrohydrodynamic direct-writing, Nanoscale, 5 (2013) 12007–12017.

O. Bas, D. D. Angella, J. G. Baldwin, N. J. Castro, F. M. Wunner, N. T. Saidy, S. Kollmannsberger, A. Reali, E. Rank, E. M. De-Juan-Pardo and D. W. Hutmacher, An integrated design, material, and fabrication platform for engineering biomechanically and biologically functional soft tissues, ACS Applied Materials and Interfaces, 9 (2017) 29430–29437.

N. Gjorevski, N. Sachs, A. Manfrin, S. Giger, M. E. Bragina, P. Ordóñez-Morñn, H. Clevers and M. P. Lutolf, Designer matrices for intestinal stem cell and organoid culture, Nature, 539 (2016) 560–564.

T. Chen, H. Jiang, Y. Zhu, X. Chen, D. Zhang, X. Li, F. Shen, H. Xia, Y. Min and K. Xie, Highly ordered 3D tissue engineering scaffolds as a versatile culture platform for nerve cells growth, Macromolecular Bioscience, 21 (2021) e2100047.

M. Shahverdi, S. Seifi, A. Akbari, K. Mohammadi, A. Shamloo and M. R. Movahhedy, Melt electrowriting of PLA, PCL, and composite PLA/PCL scaffolds for tissue engineering application, Scientific Reports, 12 (2022) 19935.

A. Daghrery, I. J. de Souza Araújo, M. Castilho, J. Malda and M. C. Bottino, Unveiling the potential of melt electrowriting in regenerative dental medicine, Acta Biomaterialia, 156 (2022) 88–109.

P. N. Bernal, P. Delrot, D. Loterie, Y. Li, J. Malda, C. Moser and R. Levato, Volumetric bioprinting of complex living- tissue constructs within seconds, Advanced Materials, 31 (2019) 1904209.

N. T. Saidy, F. Wolf, O. Bas, H. Keijdener, D. W. Hutmacher, P. Mela and E. M. De-Juan-Pardo, Biologically inspired scaffolds for heart valve tissue engineering via melt electrowriting, Small, 15 (2019) e1900873.

S. Bertlein, G. Hochleitner, M. Schmitz, J. Tessmar, M. Raghunath, P. D. Dalton and J. Groll, Permanent hydrophilization and generic bioactivation of melt electrowritten scaffolds, Advanced Healthcare Materials, 8 (2019) 1801544.

M. L. Muerza-Cascante, A. Shokoohmand, K. Khosrotehrani, D. Haylock, P. D. Dalton, D. W. Hutmacher and D. Loessner, Endosteal-like extracellular matrix expression on melt electrospun written scaffolds, Acta Biomaterialia, 52 (2017) 145–158.

C. Xie, Q. Gao, P. Wang, L. Shao, H. Yuan, J. Fu, W. Chen and Y. He, Structure-induced cell growth by 3D printing of heterogeneous scaffolds with ultrafine fibers, Materials and Design, 181 (2019) 108092.

G. Hochleitner, F. Chen, C. Blum, P. D. Dalton, B. Amsden and J. Groll, Melt electrowriting below the critical translation speed to fabricate crimped elastomer scaffolds with non-linear extension behaviour mimicking that of ligaments and tendons, Acta Biomaterialia, 72 (2018) 110–120.

J. H. Jordahl, L. Solorio, H. Sun, S. Ramcharan, C. B. Teeple, H. R. Haley, K. J. Lee, T. W. Eyster, G. D. Luker, P. H. Krebsbach and J. Lahann, 3D jet writing: functional microtissues based on tessellated scaffold architectures, Advanced Materials, 30 (2018) 1707196.

T. D. Brown, A. Slotosch, L. Thibaudeau, A. Taubenberger, D. Loessner, C. Vaquette, P. D. Dalton and D. W. Hutmacher, Design and fabrication of tubular scaffolds via direct writing in a melt electrospinning mode, Biointerphases, 7 (2012) 13.

M. Castilho, A. van Mil, M. Maher, C. H. G. Metz, G. Hochleitner, J. Groll, P. A. Doevendans, K. Ito, J. P. G. Sluijter and J. Malda, Melt electrowriting allows tailored microstructural and mechanical design of scaffolds to advance functional human myocardial tissue formation, Advanced Functional Materials, 28 (2018) 1803151.

H. Xu, I. Liashenko, A. Lucchetti, L. Du, Y. Dong, D. Zhao, J. Meng, H. Yamane and P. D. Dalton, Designing with circular arc toolpaths to increase the complexity of melt electrowriting, Advanced Materials Technologies (2022) 2101676.

Z. Zhang, H. He, W. Fu, D. Ji and S. Ramakrishna, Electro-hydrodynamic direct-Writing technology toward patterned ultra-thin fibers: advances, materials and applications, Nano Today, 35 (2020) 100942.

G. Bahcecioglu, N. Hasirci, B. Bilgen and V. Hasirci, A 3D printed PCL/hydrogel construct with zone-specific biochemical composition mimicking that of the meniscus, Biofabrication, 11 (2019) 25002.

S. Ashour and H. Xu, Melt electrowriting: A study of jet diameters and jet speeds along the spinline, Polymers for Advanced Technologies, 33 (2022) 3013–3016.

J. Meng, F. Boschetto, S. Yagi, E. Marin, T. Adachi, X. Chen, G. Pezzotti, S. Sakurai, H. Yamane and H. Xu, Design and manufacturing of 3D high-precision micro-fibrous poly (l-lactic acid) scaffold using melt electrowriting technique for bone tissue engineering, Materials and Design, 210 (2021) 110063.

J. C. Kade and P. D. Dalton, Polymers for melt electrowriting, Advanced Healthcare Materials, 10 (2021) 2001232.

F. M. Wunner, M. L. Wille, T. G. Noonan, O. Bas, P. D. Dalton, E. M. De Juan Pardo and D. W. Hutmacher, Melt electrospinning writing of highly ordered large volume scaffold architectures, Advanced Materials, 30 (2018) 1706570.

M. de Ruijter, A. Hrynevich, J. N. Haigh, G. Hochleitner, M. Castilho, J. Groll, J. Malda and P. D. Dalton, Out-of-plane 3D-printed microfibers improve the shear properties of hydrogel composites, Small, 14 (2018) 1702773.

B. Jia, L. Yu, F. Fu, L. Li, J. Zhou and L. Zhang, Preparation of helical fibers from cellulose-cuprammonium solution based on liquid rope coiling, RSC Advances, 4 (2014) 9112–9117.

N. M. Ribe, Liquid rope coiling: a synoptic view, Journal of Fluid Mechanics, 812 (2017) R2.

L. Shao, Q. Gao, C. Xie, J. Fu, M. Xiang and Y. He, Bioprinting of cell-laden microfiber: can it become a standard product?, Advanced Healthcare Materials, 8 (2019) 1900014.

Y. Jin, C. Xie, Q. Gao, X. Zhou, G. Li, J. Du and Y. He, Fabrication of multi-scale and tunable auxetic scaffolds for tissue engineering, Materials and Design, 197 (2021) 109277.

Q. Gao, C. Xie, P. Wang, M. Xie, H. Li, A. Sun, J. Fu and Y. He, 3D printed multi-scale scaffolds with ultrafine fibers for providing excellent biocompatibility, Materials Science and Engineering: C, 107 (2020) 110269.

L. Shao, Q. Gao, C. Xie, J. Fu, M. Xiang and Y. He, Synchronous 3D bioprinting of large-scale cell-laden constructs with nutrient networks, Advanced Healthcare Materials, 9 (2020) 1901142.

A. Piegat, A. Niemczyk, A. R. Boccaccini, F. M. El and L. Liverani, Hierarchical multi-layered scaffolds based on electro-fluidodynamic processes for tissue engineering, Biomedical Materials, 16 (2021).

J. Kim, E. Bakirci, K. L. O’Neill, A. Hrynevich and P. D. Dalton, Fiber bridging during melt electrowriting of poly (ε-caprolactone) and the influence of fiber diameter and wall height, Macromo-lecular Materials and Engineering, 306 (2021) 2000685.

G. Hochleitner, A. Youssef, A. Hrynevich, J. N. Haigh, T. Jungst, J. Groll and P. D. Dalton, Fibre pulsing during melt electrospinning writing, BioNanoMaterials, 17 (2016).

G. Hochleitner, T. Jungst, T. D. Brown, K. Hahn, C. Moseke, F. Jakob, P. D. Dalton and J. Groll, Additive manufacturing of scaffolds with sub-micron filaments via melt electrospinning writing, Biofabrication, 7 (2015) 35002.

A. Daneshfar, L. F. Dumée, T. C. Hughes and L. Kong, Thermally-stable photo-curing chemistry for additive manufacturing by direct melt electrowriting, Additive Manufacturing, 51 (2022) 102623.

H. Luan, Q. Zhang, T. L. Liu, X. Wang, S. Zhao, H. Wang, S. Yao, Y. Xue, J. W. Kwak, W. Bai, Y. Xu, M. Han, K. Li, Z. Li, X. Ni, J. Ye, D. Choi, Q. Yang, J. H. Kim, S. Li, S. Chen, C. Wu, D. Lu, J. K. Chang, Z. Xie, Y. Huang and J. A. Rogers, Complex 3D microfluidic architectures formed by mechanically guided compressive buckling, Science Advances, 7 (2021) j3686.

G. F. Del, G. D’Avino and P. L. Maffettone, Microfluidic formation of crystal-like structures, Lab on a Chip, 21 (2021) 2069–2094.

Acknowledgments

This work was sponsored by the Academic Cultivation and Innovation Exploration Project of Guizhou Institute of Technology (No. GZLGXM-26), and the Young Scientific Technical Talents Development Fund of Guizhou Province (No. QJHKYC [2022]359).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Additional information

Zhongfei Zou received B.Sc. degree (2013) and Ph.D. degree (2019) in mechanical engineering from Guizhou University. She is currently an Associate Professor at Guizhou Institute of Technology. Her main research interests include additive manufacturing and tissue engineering.

Rights and permissions

About this article

Cite this article

Zou, Z., Wang, Y., Shen, Z. et al. Study on suppression strategy of jet lag effect in melt electrowriting. J Mech Sci Technol 37, 4801–4808 (2023). https://doi.org/10.1007/s12206-023-0832-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0832-8