Abstract

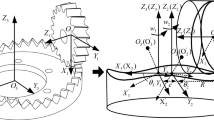

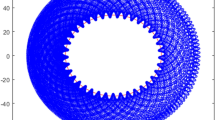

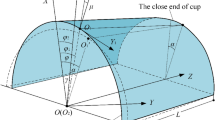

The noncircular face gear (NFG) with intersecting axes is composed of a spur gear and a NFG, which can realize the reduced and variable-speed integrated transmission between any intersecting axes. To study the contact characteristics of NFG with intersecting axes, the mutually different tooth surface mathematical model of the NFG with intersecting axes was established, and a tooth surface analysis method based on rotational projection was innovatively proposed. By using this method, the distribution characteristics of contact traces on different tooth profiles can be accurately compared through establishing the comparison reference of the middle plane on gear teeth. At the same time, the effects of installation errors and eccentricity on the contact characteristics of tooth surface were analyzed in detail. Results demonstrate that the change in the same kind of installation error has the same effect on the offset direction of the contact traces on each gear tooth. Under the same installation error, changing the eccentricity of the NFG will cause different changes in the offset of the contact traces on each gear tooth. Finally, a gear transmission device of NFG with intersecting axes was designed and manufactured. The correctness of the contact model and the analysis results were proven by the gear pair rolling experiment, which provides a theoretical basis for the design and installation of NFG with intersecting axes.

Similar content being viewed by others

Abbreviations

- c a*:

-

Tip clearance coefficient

- h a*:

-

Addendum coefficient

- i js :

-

Ratio of the tooth numbers for the NFG to the cutter

- i s2 :

-

Transmission ratio

- m s :

-

Module of the gear

- n d1 :

-

Normal vector of the spur gear

- n d2 :

-

Normal vector of the NFG

- r as :

-

Radius of the top circle of the slotting cutter

- r b1 :

-

Radius of the base circle of the spur gear

- r bs :

-

Radius of the base circle of the slotting cutter

- r d1 :

-

Position vector of the spur gear

- r d2 :

-

Position vector of the NFG

- r(φ 2):

-

Radius vector of the pitch curve of the NFG

- Z 1 :

-

Tooth numbers of the spur gear

- Z 2 :

-

Tooth numbers of the NFG

- Z s :

-

Tooth numbers of the slotting cutter

- α :

-

Pressure angle

- ϕ :

-

Eccentricity of the NFG

- κ :

-

Angle between gears

- φ 2 :

-

Rotation angle of the NFG

- φ s :

-

Rotation angle of the slotting cutter

- π :

-

Pitch radius of the slotting cutter

- ρ 1 :

-

Pitch radius of the spur gear

- ψ 1 :

-

Rotation angles of the spur gear

- ψ 2 :

-

Rotation angles of the NFG

- Δκ :

-

Axis intersection angle error

- ΔE :

-

Offset error

- Δq :

-

Axial error

References

H. Z. Song, J. G. Zheng, W. Shi, W. Liu and R. Yao, Design and research of variable speed device based on spiral noncircular gear, Journal of Mechanical Engineering, 53 (23) (2017) 101–107.

A. G. Bendefy, A. Piros and P. Horak, Arbitrary vehicle steering characteristics with changing ratio rack and pinion transmission, Advances in Mechanical Engineering, 7 (12) (2015) 1–12.

K. J. Huang, S. C. Chen, H. Komsuoglu, G. Lopes, J. Clark and P. C. Chun, Design and performance evaluation of a bio-inspired and single-motor-driven hexapod robot with dynamical gaits, Journal of Mechanisms and Robotics-Transactions of the ASME, 7 (3) (2015) 031017.

L. Sun et al., Kinematic analysis of rotary transplanting mechanism for wide-narrow row pot seedlings, Transactions of the ASABE, 59 (2) (2016) 475–485.

F. L. Litvin et al., Design, generation and stress analysis of face-gear drive with helical pinion, Computer Methods in Applied Mechanics and Engineering, 194 (36–38) (2005) 3870–3901.

F. L. Litvin, A. Fuentes and M. Howkins, Design, generation and TCA of new type of asymmetric face-gear drive with modified geometry, Computer Methods in Applied Mechanics and Engineering, 190 (43–44) (2001) 5837–5865.

Y. Z. Wang et al., Loaded tooth contact analysis of orthogonal face-gear drives, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 226 (9) (2012) 2309–2319.

J. Y. Tang and Y. P. Liu, Loaded meshing simulation of face-gear drive with spur involute pinion based on finite element analysis, Journal of Mechanical Engineering, 48 (5) (2012) 124–131.

Z. Y. Zhou, J. Y. Tang and H. Ding, Tooth contact analysis of profile-shifted non-orthogonal face gear drive with longitudinal modified pinion, China Mechanical Engineering, 27 (15) (2016) 2003–2009.

D. Q. Li, X. Z. Deng, B. Y. Wei and J. B. Li, Tooth contact analysis of face-gear based on pioin grinding modification, China Mechanical Engineering, 23 (8) (2012) 992–996.

Y. B. Shen, Z. D. Fang, N. Zhao and H. Guo, Meshing performance of modified face gear drive with helical pinion in the profile direction, China Mechanical Engineering, 18 (2008) 2219–2222.

R. C. Zhou, N. Zhao, W. Li and H. Guo, Generation, TCA and stress analysis of the face gear drive with a tapered involute pinion, Journal of Mechanical Engineering, 56 (7) (2020) 86–95.

L. V. Gang, Pitch curve design defects modification for non-circular bevel gear, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 229 (12) (2015) 2231–2241.

J. Q. Xia, Y. Y. Liu, C. M. Geng and J. B. Song, Noncircular bevel gear transmission with intersecting axes, Journal of Mechanical Design, 130 (5) (2008) 054502.

G. Figliolini and J. Angeles, Synthesis of the pitch cones of N-lobed elliptical bevel gears, Journal of Mechanical Design, 133 (3) (2011) 031002.

K. Shi, J. Q. Xia and C. J. Wang, Design of noncircular bevel gear with concave pitch curve, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 227 (3) (2012) 542–553.

J. Q. Xia, K. Shi and C. J. Wang, High-order involute modified noncircular bevel gears, Journal of Advanced Mechanical Design Systems and Manufacturing, 8 (3) (2014) 1–15.

C. Lin, H. Gong, Y. J. Hou, L. Nie and Q. L. Zeng, Design method of eccentric-high order elliptical bevel gear pair and analysis of its transmission characteristics, Transactions of the Chinese Society for Agricultural Machinery, 42 (11) (2011) 214–221.

C. Lin, Y. J. Hou, H. Gong, G. Liu and L. J. Li, Design and analysis of transmission mode for high-order deformed elliptic bevel gears, Journal of Mechanical Engineering, 47 (13) (2011) 131–139.

C. Lin, L. Nie, S. S. Li and L. Zhang, Strength calculation method of eccentric-high order elliptical bevel gear pair, Journal of Mechanical Engineering, 49 (5) (2013) 47–54.

C. Lin and C. J. He, Tooth contact analysis of elliptical bevel gear with different misalignment, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 233 (7) (2019) 2516–2525.

D. W. Liu, G. H. Wang and T. Z. Ren, Transmission principle and geometrical model of eccentric face gear, Mechanism and Machine Theory, 109 (2017) 51–64.

D. W. Liu, T. Z. Ren and X. Jin, Meshing theory of speed integration gear, Journal of Mechanical Engineering, 52 (15) (2016) 1–7.

G. H. Wang, D. W. Liu, W. H. Yang and T. Z. Ren, Analysis of tooth contact of speed integration gear with assembly error, Journal of Mechanical Transmission, 42 (4) (2018) 102–106.

S. J. Wang, S. Khatir and M. A. Wahab, Proper orthogonal decomposition for the prediction of fretting wear characteristics, Tribology International, 152 (2020) 106545.

T. Y. Yue and M. A. Wahab, Finite element analysis of fretting wear under variable coefficient of friction and different contact regimes, Tribology International, 107 (2017) 274–282.

Acknowledgments

This work was supported by Hebei Natural Science Foundation (Grant No. E2022203006) and the University Science and Technology Research Project of Hebei Province (Grant No. QN2020266).

Author information

Authors and Affiliations

Corresponding author

Additional information

Dawei Liu is an Associate Professor of the College of Mechanical Engineering, Yanshan University, Qinhuangdao, China. He received his Ph.D. in Mechanical Design and Theory from Yanshan University. His research interests include new mechanical transmission, new energy vehicle and tactile sensor.

Rights and permissions

About this article

Cite this article

Liu, D., Li, H., Lv, Z. et al. Mutually different tooth surface contact characteristics of a noncircular face gear with intersecting axes. J Mech Sci Technol 37, 1903–1912 (2023). https://doi.org/10.1007/s12206-023-0327-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0327-7