Abstract

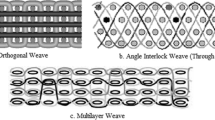

This study is devoted to reveal the influence of weaving architectures and impact locations on the ballistic resistance of UHMWPE (ultrahigh high molecular weight polyethylene) fabrics. Firstly, a mesoscopic model of UHMWPE fabric is established and the accuracy of the numerical method is verified. Subsequently, the models with different weaving architectures are further established, and the impact resistance performances are evaluated. Finally, the influence factors on the fabric ballistic resistance is explored. It is proved that the ballistic resistance of UHMWPE fabric mainly dominated by the tensile strength of yarn under high-velocity impact. The plain fabric shows best anti-ballistic performance, while basket and woven fabric are slightly inferior. The damage pattern of fabrics with different weaving architectures changes greatly. In addition, this study proposes a residual impact velocity correction model for projectile based on the probability distribution of impact positions, which can better characterize the protective ability of fiber fabrics.

Similar content being viewed by others

Abbreviations

- S n(i):

-

The stress of the element in the direction i

- S t(i):

-

The fracture stress in the direction i

- E(X):

-

The weighted velocity reduction

- x k :

-

The possible value of the velocity reduction

- p k :

-

The corresponding probability that xk occurs

References

A. Mouritz et al., Review of applications for advanced three-dimensional fibre textile composites, Composites Part A: Applied Science and Manufacturing, 30 (12) (1999) 1445–1461.

X. Wei et al., Three-dimensional numerical modeling of composite panels subjected to underwater blast, Journal of the Mechanics and Physics of Solids, 61 (6) (2013) 1319–1336.

C. Tham et al., Ballistic impact of a KEVLAR helmet: Experiment and simulations, International Journal of Impact Engineering, 35 (5) (2008) 304–318.

A. Tabiei and G. Nilakantan, Ballistic impact of dry woven fabric composites: a review, Applied Mechanics Reviews, 61 (1) (2008) 129–137.

Y. Yang et al., Multi-scale finite element modelling of ballistic impact onto woven fabric involving fiber bundles, Composite Structures, 267 (2021) 113856.

C. Ha-Minh et al., Numerical multi-scale modeling for textile woven fabric against ballistic impact, Computational Materials Science, 50 (7) (2011) 2172–2184.

S. Sockalingam et al., Recent advances in modeling and experiments of Kevlar ballistic fibrils, fibers, yarns and flexible woven textile fabrics — a review, Textile Research Journal, 87 (8) (2017) 984–1010.

Z. Gao and L. Chen, A review of multi-scale numerical modeling of three-dimensional woven fabric, Composite Structures, 263 (3) (2021) 113685.

P. Turner et al., Dynamic response of orthogonal three-dimensional woven carbon composite beams under soft impact, Journal of Applied Mechanics, 82 (12) (2015) 121008–121020.

M. Bannister et al., The manufacture of glass/epoxy composites with multilayer woven architectures, Composites Part A Applied Science and Manufacturing, 29 (3) (1998) 293–300.

H. Miao et al., The numerical and experimental investigation on low-velocity impact response of composite panels: effect of fabric architecture, Composite Structures, 227 (2019) 111343.

C. Yen et al., Dynamic characterization and modeling of 3d woven composite ballistic behavior, Proceedings of the American Society of Composites, 26th Annual Technical Conference (2011).

B. Kazemianfar and M. R. Nami, Can a 3D woven GFRP composite really provide better impact resistance compared to a 2D woven GFRP composite at all of the thicknesses?, Structures, 35 (2022) 36–45.

C. Yang et al., Influences of weaving architectures on the impact resistance of multi-layer fabrics, Materials and Design, 85 (Nov. 15) (2015) 282–295.

H. Wang et al., On the impact response of UHMWPE woven fabrics: experiments and simulations, International Journal of Mechanical Sciences (2021) 106574.

Y. Xie et al., Effects of textile structure and projectile geometry on ballistic performance of UHMWPE textiles, Composite Structures, 279 (2022) 114785.

H. Wang et al., Tensile properties of UHMWPE single yarn at different strain rates, Journal of Composite Materials, 54 (11) (2015) 1453–1466.

M. Rao et al., Modeling the effects of yarn material properties and friction on the ballistic impact of a plain-weave fabric, Composite Structures, 89 (4) (2009) 556–566.

A. Gasser et al., Mechanical behaviour of dry fabric reinforcements. 3D simulations versus biaxial tests, Computational Materials Science, 17 (1) (2000) 7–20.

S. Min et al., Numerical study on mechanisms of angle-plied panels for ballistic protection, Materials and Design, 90 (2016) 896–905.

Abaqus Documentation, SIMULIA User Assistance, Dassault Systems Simulia Corporation (2017).

Z. Yuan et al., Identification of the elastic constant values for numerical simulation of high velocity impact on Dyneema woven fabrics using orthogonal experiments, Composite Structures, 204 (2018) 178–191.

Y. Yang and X. Chen, Influence of fabric architecture on energy absorption efficiency of soft armour panel under ballistic impact, Composite Structures, 224 (2019) 111015.

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Grant Numbers 11502180.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Zihan Zhu is a master degree candidate of Green & Smart River-Sea-Going Ship, Cruise and Yacht Research Center, Wuhan University of Technology, China. His research interests include composite materials, impact dynamics.

Fang Liu is an Associate Professor of the School of Trans-portation, Wuhan University of Technology, Wuhan, China. She received her Ph.D. in Solid Mechanics from Institute of Mechanics, Chinese Academy of Sciences. Her research interests include elasto-plastic damage constitu-tive relations and structural responses.

Yonggiang Zhang is an Associate Research Fellow in Institute of Fluid Physics, China Academy of Engineering Physics. He got his Master degree from Harbin Institute of Technology and his research interests include shock dynamics of material.

Rights and permissions

About this article

Cite this article

Zhu, Z., Zhou, H., Kong, X. et al. Influences of weaving architectures and impact locations on the ballistic resistance of UHMWPE fabric. J Mech Sci Technol 36, 6005–6014 (2022). https://doi.org/10.1007/s12206-022-1116-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-1116-4