Abstract

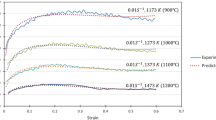

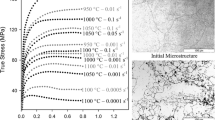

The traditional flow models with an emphasis on Voce family flow models are criticized using a typical monotonic strain-hardening material and a double strain-hardening (DSH) material. The DSH behavior is quantitatively expressed in detail using SUS304. They are, however, negatively evaluated especially for the DSH material that simultaneously experiences wide ranges of strain (e.g., during cold forging). After characterizing the Voce strain-hardening model (VSHM) with an emphasis on not only asymptotic stress but also a new concept of extremum curvature strain (ECS), the Voce-Ludwik model coupled with ECS is presented to describe the DSH flow behavior, based on the mathematical characteristics of VSHM. It has been found that the proposed Voce-Ludwik model can reflect DSH behavior using the nature of the strain at the ECS, which has the distinct advantage of modeling thermoviscoplastic flow behaviors of the DSH materials including stainless steels, copper alloys, aluminum alloys, etc.

Similar content being viewed by others

References

J. G. Eom, Y. H. Son, S. W. Jeong, S. T. Ahn, D. J. Yoon and M. S. Joun, Effect of strain hardening capability on plastic deformation behaviors of material during metal forming, Materials and Design, 54 (2014) 1010–1018.

S. W. Lee, J. M. Lee and M. S. Joun, On critical surface strain during hot forging of lubricated aluminum alloy, Tribology International, 141 (2020) 105855.

P. Ludwik, Elemente der Technologischen Mechanik, Verlag Von Julius Springer, Berlin (1909).

E. Voce, The relationship between stress and strain for homogeneous deformation, Journal of the Institute of Metals, 74 (1948) 537–562.

J. H. Hollomon, Tensile deformation, Aime Trans, 162 (1945) 1–22.

H. W. Swift, Plastic instability under plane stresses, Journal of the Mechanics and Physics of Solids, 1 (1) (1952) 1–18.

J. F. Kreyca, State parameter-based modelling of stress-strain curves in aluminum alloys, Ph.D. Thesis, TU Wien (2017).

S. Tu, X. Ren, J. He and Z. Zhang, Stress-strain curves of metallic materials and post-necking strain hardening characterization: a review, Fatigue and Fracture of Engineering Materials and Structures, 43 (1) (2020) 3–19.

R. Liang and A. S. Khan, A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures, Int. J. Plast., 15 (9) (1999) 963–980.

R. Chales, A. S. M. Cardoso, J. M. Pardal, S. S. M. Tavares, M. M. Silva and D. A. P. Reis, Modeling and numerical validation of stress-strain curves of maraging steels, grade 300 and 350 under hydrogen embrittlement, Materials Research, 24 (3) (2021).

J. Abellán-García, J. A. Fernández-Gómez, N. Torres-Castellanos and A. M. Núñez-López, Tensile behavior of normal-strength steel-fiber green ultra-high-performance fiber-reinforced concrete, ACI Materials Journal, 118 (1) (2021) 127–138.

H. D. Kweon, J. W. Kim, O. S. Song and D. H. Oh, Determination of true stress-strain curve of type 304 and 316 stainless steels using a typical tensile test and finite element analysis, Nuclear Engineering and Technology, 53 (2) (2021) 647–656.

J. B. Byun, M. K. Razali, C. J. Lee, I. D. Seo, W. J. Chung and M. S. Joun, Automatic multi-stage cold forging of an SUS304 ball-stud with a hexagonal hole at one end, Materials, 13 (22) (2020) 5300–5316.

S. K. Paul, S. Roy, S. Sivaprasad, H. N. Bar and S. Tarafder, Identification of post-necking tensile stress-strain behavior of steel sheet: an experimental investigation using digital image correlation technique, Journal of Materials Engineering and Performance, 27 (2018) 5736–5743.

J. Li, G. Yang, T. Siebert, M. F. Shi and L. Yang, A method of the direct measurement of the true stress-strain curve over a large strain range using multi-camera digital image correlation, Optics and Lasers in Engineering, 107 (2018) 194–201.

M. Quanjin, M. R. Rejab, Q. Halim, M. N. Merzuki and M. A. Darus, Experimental investigation of the tensile test using digital image correlation (DIC) method, Materials Today: Proceedings, 27 (2020) 757–763.

M. Kim, B. Gu and S. Hong, Determination of post-necking stress-strain relationship for zirconium low-oxidation based on actual cross-section measurements by DIC, Journal of Mechanical Science and Technology, 34 (10) (2020) 4211–4217.

Q. Zheng, N. Mashiwa and T. Furushima, Evaluation of large plastic deformation for metals by a non-contacting technique using digital image correlation with laser speckles, Materials and Design, 191 (2020) 108626–108639.

P. D. Versaillot, Z. L. Zhao and Y. F. Wu, A new theoretical method for predicting the elastoplastic behavior of ductile metallic materials, International Journal of Mechanical Sciences, 200 (2021) 106450.

Y. C. Lin and X.-M. Chen, A critical review of experimental results and constitutive descriptions for metals and alloys in hot working, Materials and Design, 32 (4) (2011) 1733–1759.

A. Gavrus, E. Massoni and J. L. Chenot, An inverse analysis using a finite element model for identification of rheological parameters, Journal of Materials Processing Technology, 60 (1–4) (1996) 447–454.

R. Mahnken and E. Stein, A unified approach for parameter identification of inelastic material models in the frame of the finite element method, Computer Methods in Applied Mechanics and Engineering, 136 (3–4) (1996) 225–258.

M. S. Joun, J. G. Eom and M. C. Lee, A new method for acquiring true stress-strain curves over a large range of strains using a tensile test and finite element method, Mechanics of Materials, 40 (7) (2008) 586–596.

M. K. Razali, M. S. Joun and W. J. Chung, A novel flow model of strain hardening and softening for use in tensile testing of a cylindrical specimen at room temperature, Materials, 14 (17) (2021) 4876.

J. E. Hockett and O. D. Sherby, Large strain deformation of polycrystalline metals at low homologous temperatures, Journal of the Mechanics and Physics of Solids, 23 (2) (1975) 87–98.

M. Dunand and D. Mohr, On the predictive capabilities of the shear modified Gurson and the modified Mohr-Coulomb fracture models over a wide range of stress triaxialities and lode angles, Journal of the Mechanics and Physics of Solids, 59 (7) (2011) 1374–1394.

A. Poulon-Quintin, J. B. Vogt, V. Shivanyuk and D. J. Foct, Characterisation and understanding of TRIP steels, Journal de Physique IV (Proceedings), 118 (1) (2004) 355–368.

P. Koc and B. Štok, Computer-aided identification of the yield curve of a sheet metal after onset of necking, Computational Materials Science, 31 (2004) (1–2) 155–168.

J. H. Kim, A. Serpanitie, F. Barlat, F. Pierron and M. G. Lee, Characterization of the post-necking strain hardening behavior using the virtual fields method, International Journal of Solids and Structures, 50 (24) (2013) 3829–3842.

Y. D. Wang, S. H. Xu, S. B. Ren and H. Wang, An experimental-numerical combined method to determine the true constitutive relation of tensile specimens after necking, Advances in Materials Science and Engineering, 2016 (2016) 1–21.

I. Jeník, P. Kubík, F.  ebek, J. Hůlka and J. PetruŠka, Sequential simulation and neural network in the stress-strain curve identification over the large strains using tensile test, Archive of Applied Mechanics, 87 (2017) 1077–1093.

J. Chen, Z. Guan and C. Yang, Inverse determination of the flow curve in large range of strains for cylindrical tensile specimen, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 234 (11) (2020) 2256–2265.

J. G. Eom, M. C. Kim, S. W. Lee, H. Y. Ryu and M. S. Joun, Evaluation of damage models by finite element prediction of fracture in cylindrical tensile test, Journal of Nanoscience and Nanotechnology, 14 (10) (2014) 8019–8023.

M. Considère, Memoir on the use of iron and steel in structures, Ann. Ponts Chaussees, 9 (1885) 574–775.

M. S. Joun, I. S. Choi, J. G. Eom and M. C. Lee, Finite element analysis of tensile testing with emphasis on necking, Computational Materials Science, 41 (1) (2007) 63–69.

Y. S. Kim, P. Q. Tuan and C. I. Kim, New stress-strain model for identifying plastic deformation behavior of sheet materials, Journal of the Korean Society for Precision Engineering, 34 (4) (2017) 273–279.

E. El-Magd and M. Abouridouane, Characterization, modelling and simulation of deformation and fracture behaviour of the light-weight wrought alloys under high strain rate loading, International Journal of Impact Engineering, 32 (5) (2006) 741–758.

K. Omer, S. Kim, C. Butcher and M. Worswick, Characterizing the constitutive properties of AA7075 for hot forming, Journal of Physics: Conference Series, 896 (1) (2017) 012054.

G. Z. Voyiadjis and F. H. Abed, Microstructural based models for BCC and FCC metal with temperature and strain rate dependency, Mechanics of Materials, 37 (2–3) (2005) 355–378.

H. Mecking and U. F. Kocks, Kinetics of flow and strain-hardening, Acta Metallurgica, 29 (11) (1981) 1865–1875.

Y. Bergström, Y. Granbom and D. Sterkenburg, A dislocation-based theory for the deformation hardening behavior of DP steels: Impact on martensite content and ferrite grain size, Journal of Metallurgy, 2010 (2010).

O. Hering, F. Kolpak and A. E. Tekkaya, Flow curves up to high strains considering load reversal and damage, International Journal of Material Forming, 12 (2019) 955–972.

G. R. Johnson and W. H. Cook, A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, Proc. 7th. Int. Symp. Ballistics, Hague, Netherlands (1983) 541–547.

Acknowledgments

This work was partly supported by Korea Institute of Energy Technology Evaluation and Planning (KETEP) (20214 000000 520, Human Resource Development Project in Circular Re-manufacturing Industry) and Korea Evaluation Institute of Industrial Technology (KEIT) (20003950, Development and application of die fatigue fracture prediction system for intelligent and smart precision cold forming.) grant funded by the Korea government (MOTIE).

Author information

Authors and Affiliations

Corresponding author

Additional information

Jong Bok Byun is a training researcher of Engineering Research Institute, Gyeongsang National University, Jinju, Republic of Korea. He studied mechanical engineering in Department of Mechanical Engineering of Gyeongsang National University for his M. S. degree. His major research interest is the material modeling, finite element simulation of metal forming processes and their process optimal design.

Chang Woon Jee is a senior researcher of Technical Research Laboratories, POSCO, Gwangyang, Republic of Korea. He received his M.S. degree from the Department of Mechanical Engineering of KAIST. His research interests include characterization of material properties and engineering of continuous steel processing lines such as continuous galvanizing lines and continuous annealing lines for automotive steels.

Il Dong Seo is a technical advisor of Daedong Co., Ltd., Gimhae, Republic of Korea. He received his M.S. degree from the Department of Mechanical Engineering of KAIST. His interests lie in application of high-strength materials to automobiles and development of novel mechanical structures using metal-formed parts and their economical manufacturing.

Man Soo Joun is a Professor of School of Mechanical and Aerospace Engineering of Gyeongsang National University, Jinju, Republic of Korea. He received his Ph.D. from the Department of Mechanical Engineering of POSTECH. His major interests include metal forming simulation technologies with an emphasis on their industrial applications, specifically including flow analysis, heat transfer analysis, metallurgical analysis, process modelling and design optimization, and flow and metallurgical modellings.

Rights and permissions

About this article

Cite this article

Byun, J., Jee, C., Seo, I. et al. Characterization of double strain-hardening behavior using a new flow of extremum curvature strain of Voce strain-hardening model. J Mech Sci Technol 36, 4115–4126 (2022). https://doi.org/10.1007/s12206-022-0730-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0730-5