Abstract

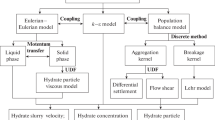

The hydrate particle aggregation is crucial for the flow safety of oil and gas pipelines. In this paper, coupled with the Eulerian-Eulerian model, k−ε turbulence model and the population balance model considering the hydrate aggregation and breakage, the hydrate aggregation process is studied in the bend, and the change of the average particle size under different hydrate volume fractions is discussed. The results show that the hydrate aggregation process includes two stages in the bend, namely the rapid growth and the dynamic equilibrium. In the rapid growth stage, both the hydrate concentration and particle size in the elbow increase rapidly, and the high concentration and large particle size regions on the inside of the elbow also increase significantly. Furthermore, two types of aggregates are formed on the inside of the elbow. One is a small amount of large-particle aggregates, while the other is the relatively high concentration of medium-size aggregates. Besides, the uniform suspension with a smaller concentration and particle size is distributed on the outside of the elbow, but there are also large-size particles that aggregate and adhere near the wall of pipe. As the hydrate volume fraction increases, the hydrate average particle size increases. High concentration hydrate reaches dynamic equilibrium faster during the flow process.

Similar content being viewed by others

Abbreviations

- l :

-

Water phase

- s :

-

Hydrate particle phase

- ϕ :

-

Volume fraction

- ρ :

-

Density, kg/m3

- u :

-

Velocity vector, m/s

- τ :

-

Stress tensor, Pa

- P :

-

Pressure, Pa

- ∇P S :

-

Pressure generated by particles collision, Pa

- F :

-

Interphase momentum exchange term, kg/(m · s)2

- F d :

-

Interphase drag force

- F t :

-

Turbulent diffusion force

- u r :

-

Interphase relative velocity, m/s

- μ t,m :

-

Turbulent viscosity, kg/(m · s)

- σ d :

-

Planck diffusion coefficient

- k ls :

-

Momentum transfer coefficient

- μ :

-

Dynamic viscosity, kg/m · s

- C D :

-

Drag coefficient

- D :

-

Hydrate particle size, um

- n :

-

Quantity density

- g(D∣D′):

-

The particle size distribution of the child particles

- V :

-

Settling velocity, m/s

- β :

-

Collision frequency, m3/s

- β br (D′):

-

Breakage frequency, 1/s

- G :

-

Absolute velocity gradient

- η :

-

Kolmogorov microscale

- v :

-

Kinematic viscosity

- ε :

-

Turbulent energy dissipation rate

- a :

-

Aggregation efficiency

- H :

-

Hamek constant

- R :

-

Harmonic radius of the two colliding particles

- Ωbr :

-

Breakage rate

- ξ :

-

Dimensionless eddy size

References

E. G. Hammer Schmidt, Formation of gas hydrates in natural gas transmission lines, Industrial and Engineering Chemistry, 26(8) (1934) 851–855, DOI: https://doi.org/10.1021/ie50296a010.

E. D. Sloan and C. A. Koh, Clathrate Hydrates of Natural Gases, 3rd ed, CRC Press: Boca Raton, FL (2008).

Y. H. Sohn et al., Hydrate plug formation risk with varying water cut and inhibitor concentrations, Chemical Engineering Science, 126 (2015) 711–718, DOI: https://doi.org/10.1016/j.ces.2015.01.016.

S. Wang, Studies of Gas and Water Migration and Particle Agglomeration Mechanisms in Natural Gas Hydrate Exploitation, Dalian University of Technology (2018) 81–107.

Y. Li, Research on the Aggregation Behavior of Gas-Hydrate Particles in the Flowing Field, Civil Aviation University of China (2013) 9–31.

W. Wang et al., Study of agglomeration characteristics of hydrate particles in oil/gas pipelines, Advances in Mechanical Engineering, 7(1) (2014) 1–6, DOI: https://doi.org/10.1155/2014/457050.

H. M. Stoner and C. A. Koh, Perspective on the role of particle size measurements in gas hydrate agglomeration predictions, Fuel, 304 (2021) 1–12, DOI: https://doi.org/10.1016/j.fuel.2021.121385.

B. V. Balakin, A. C. Hoffmann and P. Kosinski, Experimental study and computational fluid dynamics modeling of deposition of hydrate particles in a pipeline with turbulent water flow, Chemical Engineering Science, 66(4) (2011) 755–765, DOI: https://doi.org/10.1016/j.ces.2010.11.034.

B. V. Balakin, A. C. Hoffmann and P. Kosinski, Population balance model for nucleation, growth, aggregation, and breakage of hydrate particles in turbulent flow, AIChE Journal, 56(8) (2010) 2052–2062, DOI: https://doi.org/10.1002/aic.12122.

B. V. Balakin, S. Lo and P. Kosinski, Modelling agglomeration and deposition of gas hydrates in industrial pipelines with combined CFD-PBM technique, Chemical Engineering Science, 153 (2016) 45–57, DOI: https://doi.org/10.1016/j.ces.2016.07.010.

G. C. Song et al., Hydrate agglomeration modeling and pipeline hydrate slurry flow behavior simulation, Chinese Journal of Chemical Engineering, 27 (2018) 32–43, DOI: https://doi.org/10.1016/j.cjche.2018.04.004.

S. Yao et al., Numerical simulation of hydrate slurry flow characteristics in vertical pipes based on population balance theory, Int. J. Oil, Gas and Coal Technology, 25(3) (2020) 319–339, DOI:https://doi.org/10.1504/IJOGCT.2020.110389.

X. Cao et al., Influences of particle micro behavior on gas-hydrate slurry flow pattern in pipeline, Journal of Natural Gas Science and Engineering, 93 (2021) 1–13, DOI: https://doi.org/10.1016/j.jngse.2021.104057.

B. B. Nayak, D. Chatterjee and A. N. Mullick, Numerical prediction of flow and heat transfer characteristics of water-fly ash slurry in a 180° return pipe bend, International Journal of Thermal Sciences, 113(1) (2017) 100–115, DOI: https://doi.org/10.1016/j.ijthermalsci.2016.11.019.

T. Jin et al., Numerical modeling for the flow and heat transfer of slush nitrogen in a horizontal pipe based on population balance equations, Applied Thermal Engineering, 123(6) (2017) 301–309, DOI: https://doi.org/10.1016/j.applthermaleng.2017.05.077.

M. Rafique and M. P. Dudukovi, Computational modeling of gas-liquid flow in bubble columns, Reviews in Chemical Engineering, 20(3) (2004) 225–375, DOI: https://doi.org/10.1515/REVCE.2004.20.3-4.225.

A. Sokolichin, G. Eigenberger and A. Lapin, Simulation of buoyancy driven bubbly flow: established simplifications and open questions, AIChE Journal, 50 (2004) 24–45, DOI: https://doi.org/10.1002/aic.10003.

D. Y. Liu, Fluid Dynamics of Two-phase Systems, Higher Education Press, China (1993).

J. Ding and D. Gidaspow, A bubbling fluidization model using kinetic theory of granular flow, AIChE Journal, 36(4) (1990) 523–538, DOI: https://doi.org/10.1002/aic.690360404.

C. L. Wu, K. Nandakumar and A. S. Berrouk, Enforcing mass conservation in DPM-CFD models of dense particulate flows, Chemical Engineering Journal, 174(1) (2011) 475–481, DOI: https://doi.org/10.1016/j.cej.2011.08.033.

A. S. Berrouk et al., Heavy particle dispersion from a point source in turbulent pipe flow, International Journal of Multiphase Flow, 34(10) (2008) 916–923, DOI: https://doi.org/10.1016/j.ijmultiphaseflow.2008.04.002.

P. Willi, Fundamental considerations on suspension rheology, Ceramics-Silikaty, 48(1) (2004) 6–13.

H. M. Hulburt and S. Katz, Some problems in particle technology: a statistical mechanical formulation, Chemical Engineering Science, 19(8) (1964) 555–574, DOI: https://doi.org/10.1016/0009-2509(64)85047-8.

C. J. Meyer and D. A. Deglon, Particle collision modeling- a review, Minerals Engineering, 24(8) (2011) 719–730, DOI: https://doi.org/10.1016/j.mineng.2011.03.015.

T. R. Camp and P. C. Stein, Velocity gradients and internal work in fluid motion, Journal of the Boston Society of Civil Engineers, 30(4) (1943) 219–237.

P. G. Saffman and J. S. Turner, On the collision of drops in turbulent clouds, Journal of Fluid Mechanics, 1(1) (1956) 16–30, DOI: https://doi.org/10.1017/S0022112056000020.

J. Abrahamson, Collision rates of small particles in a vigorously turbulent fluid, Chemical Engineering Science, 30(11) (1975) 1371–1379, DOI: https://doi.org/10.1016/0009-2509(75)85067-6.

F. Lehr, M. Millies and D. Mewes, Bubble-size distributions and flow fields in bubble columns, AIChE Journal, 48(11) (2002) 2426–2443, DOI: https://doi.org/10.1002/aic.690481103.

Acknowledgements

This work was supported by National Natural Science Foundation of China (Major Program No. U19B200052), Science and Technology Innovation Seedling Project of Sichuan Province, China (No. 2021079), National Natural Science Foundation Young Scientists Fund of China (No. 51904259), Sichuan Outstanding Youth Fund Program, China (No.19JCQN0081) and School-level Key Program of Chengdu Technological University, China (No. 210518).

Author information

Authors and Affiliations

Corresponding author

Additional information

Cheng Yu received the M.E. degree in mechatronics engineering from Southwest Petroleum University, China, in 2017, where she is currently pursuing the Ph.D. degree. Simultaneously, she has been a teacher in Chengdu Technological University. Her research interests include multiphase fluid mechanics, hydrate and fluid computing simulation.

Lin Wang is an Associate Professor of mechatronics engineering, Southwest Petroleum University, China. His research interests include the fluid-solid coupling dynamics, multiphase pipe flow, and oil and gas field gathering and transportation technology.

Chuanjun Han is a Professor of mechatronics engineering, Southwest Petroleum University, China. His research interests include the oil and gas equipment modern design, fluid mechanics, and modern numerical simulation.

Rights and permissions

About this article

Cite this article

Yu, C., Wang, L., Han, C. et al. Aggregation behavior analysis of hydrate particles in the bend pipe based on the population balance model. J Mech Sci Technol 36, 3477–3486 (2022). https://doi.org/10.1007/s12206-022-0625-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0625-5