Abstract

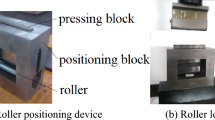

The acquisition of high-quality surface images is an important step in the surface damage detection of bearing rollers. In order to improve the quality of image acquisition and take into account the acquisition efficiency, an image acquisition system is designed in this paper. Through the dynamic analysis method, it is proved that the amplitude of the roller itself has little effect on the image in the acquisition process. Subsequently, the response surface method is used to analyze the interactive effect of the light source intensity, incident angle and roller speed on the image quality, and the optimal acquisition parameter setting value suitable for this acquisition system is found. Finally, the image of the bearing cylindrical roller with surface defects is collected to obtain a clear surface image. This paper can provide reference for the design of high level image acquisition system.

Similar content being viewed by others

References

H. Saruhan and M. Kam, Experimental spectral analysis of split sleeve bearing clearance effect on a rotating shaft system, Electronic Journal of Machine Technologies, 13 (2016) 1–8.

M. Kam and H. Saruhan, Vibration damping capacity of deep cryogenic treated AISI 4140 steel shaft supported by rolling element bearings, Materials Testing, 63 (8) (2021) 742–747.

M. Kam et al., Vibration damping capacity of a rotating shaft heat treated by various procedures, Materials Testing, 63 (10) (2021) 966–969.

M. Kam, H. Saruhan and A. Pekci, Experimental analysis of vibration damping capabilities of sleeve bearings printed using FDM method, Journal of Polytechnic, 25 (1) (2022) 137–143.

Ö. ŞengÜl and A. P. D. M. Kam, Analysis of radial tire design and dynamic analysis for sustainable production, International Marmara Science and Social Sciences Congress-IMASCON 2019 Spring, Kocaeh (2019).

M. Kam and H. Saruhan, Experimental vibration analysis of cryogenic treated shafts supported by journal and rolling element bearings-kriyojenik ilem uygulanm millerin yuvarlanmal ve kaymal yataklarda deneysel titreim analizi, Journal of Polytechnic, 21 (1) (2019) 129–134.

B. Chen, Z. Yan and W. Chen, Defect detection for wheel-bearings with time-spectral kurtosis and entropy, Entropy, 16 (1) (2014) 607–626.

E. N. Malamas et al., A survey on industrial vision systems, applications and tools, Image and Vision Computing, 21 (2) (2003) 171–188.

S. S. Martínez et al., Quality inspection of machined metal parts using an image fusion technique, Measurement, 111 (2017) 374–383.

Z. Ren et al., State of the art in defect detection based on machine vision, International Journal of Precision Engineering and Manufacturing-Green Technology, 9 (2021) 661–691.

H. J. Liu, Y. N. Wang and D. Feng, Image capture in machine vision, Computer and Information Technology (2003).

J. Wang, X. Qu and Y. Zhao, Design of lighting system in multi vision detection, Electro-Optic Technology Application, 24 (4) (2009) 1–5.

N. Zhang and C. Lu, Wind turbine blade defect image acquisition system, Journal of Physics: Conference Series (2020) 012086.

N. Prappacher et al., Defect detection on rolling element surface scans using neural image segmentation, Applied Sciences, 10 (9) (2020) 3290.

S. Wen, Z. Chen and C. Li, Vision-based surface inspection system for bearing rollers using convolutional neural networks, Applied Sciences, 8 (12) (2018) 2565.

J. P. Yun et al., Vision-based surface defect inspection for thick steel plates, Optical Engineering, 56 (5) (2017) 053108.

L. M. Xu et al., Light source optimization for automatic visual inspection of piston surface defects, The International Journal of Advanced Manufacturing Technology, 91 (5–8) (2016) 2245–2256.

Y.-J. Chen, J.-C. Tsai and Y.-C. Hsu, A real-time surface inspection system for precision steel balls based on machine vision, Measurement Science and Technology, 27 (7) (2016) 074010.

Z. Wang et al., Realtime vision-based surface defect inspection of steel balls, Transactions of Tianjin University, 21 (1) (2015) 76–82.

H. Shen et al., Bearing defect inspection based on machine vision, Measurement, 45 (4) (2012) 719–733.

Y. Do, S. Lee and Y. Kim, Vision-based surface defect inspection of metal balls, Measurement Science and Technology, 22 (10) (2011) 107001.

Y. Bao et al., The design and dynamics analysis of cylindrical roller surface unfolding mechanism, Advances in Mechanical Design, Springer, Singapore (2020).

H. Feng, Q. Deng and Z. Song, Analysis of the simulation model based on remote sensing imaging under vibration, Opto-Electron. Eng., 40 (1) (2013) 7.

W. Wang et al., Approximate Fokker-Planck-Kolmogorov equation analysis for asymmetric multistable energy harvesters excited by white noise, Journal of Statistical Mechanics: Theory and Experiment, 2021 (2) (2021) 023407.

A. Förster, L. P. Scheidt and J. Wallaschek, Approximate solution of the Fokker-Planck equation for a multi-degree of freedom frictionally damped bladed disk under random excitation, ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo (2018).

K. L. Johnson and G. G. Gray, Development of corrugations on surfaces in rolling contact, Archive Proceedings of the Institution of Mechanical Engineers, 189 (1975) 567–580.

N. D. Londhe et al., Extended hertz theory of contact mechanics for case-hardened steels with implications for bearing fatigue life, Journal of Tribology, 140 (2) (2018) 021401.

W. Wanting et al., Study of image quality degraded by los Jitter, Chinese Journal of Lasers, 41 (4) (2014) 0409001.

W. Le et al., Line-structured light imaging method of rail profile based on polarization fusion, Acta Optica Sinica, 40 (22) (2020) 2211001.

M. Banitalebi-Dehkordi et al., An image quality assessment algorithm based on saliency and sparsity, Multimedia Tools and Applications, 78 (9) (2019) 11507–11526.

L. I. Xue and M. Jiang, A comparison of sharpness functions based on microscopes, Optical Instruments, 40 (1) (2018) 28–38.

X. H. Wang et al., Deconvolution deblurring algorithm based on no-reference image quality evaluation, Optical Instruments, 4 (41) (2019) 14–21.

Acknowledgments

This project was supported by Harbin Science and Technology Innovation Talent Research Special Fund Project (2017RAQXJ060), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Yudong Bao received his B.Sc. degree in 2010 and his Ph.D. degree in 2015 from Northeast Forestry University. He is an Associate Professor and a M.Sc. Supervisor in Harbin University of Science and Technology. And his main research interests include bearing and inspection technology.

Rights and permissions

About this article

Cite this article

Bao, Y., Wu, L., Dai, Y. et al. Research on surface image acquisition system of train bearing cylindrical roller. J Mech Sci Technol 36, 4353–4361 (2022). https://doi.org/10.1007/s12206-022-0602-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0602-z