Abstract

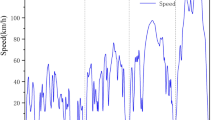

We studied the transient driving power of an oil pump for 1.6 L PFI engine in a passenger car under the new European driving cycle (NEDC) and worldwide harmonized light-duty test cycle (WLTC), and analyze the influence of control strategies on the energy-saving potential of the oil pump. To measure the dynamic matching conditions between the oil pump supplements and the engine lubrication requirements, a test system of the engine lubrication performance in passenger cars was built using the hardware-in-the loop (HiL) method. Subsequently, a set of acceleration and deceleration test cycles was designed to represent the harsh lubrication conditions in the standard driving cycles, so as to facilitate analysis of the reasons for driving energy loss of oil pump under transient conditions. Further, three kinds of control strategies of oil pumps used in engine design were analyzed and a comparison was given on their effects on the driving energy consumption and lubrication safety under NEDC and WLTC. The test results indicate that the hydraulic energy losses caused by the pressure relief valve opening and lubricant flow hysteresis were the main reasons for the driving energy increments in the oil pump under transient conditions. In addition, the variable lubrication flow control strategies were effective in reducing the pressure relief valve opening duration and hydraulic energy losses, yet had minimal influence on the hydraulic energy losses caused by lubricant flow hysteresis. Compared with the constant one, 2-stage variable control strategy reduced the overall driving energy by 42.7 % and 46 % in NEDC and WLTC, respectively, while the corresponding hydraulic energy output fulfilled the requirements of engine lubrication. By the 2-stage oil pump, the total fuel consumption of vehicle in WLTC was reduced by 1.93 % and 0.94 % at 25 °C and 100 °C, respectively.

Similar content being viewed by others

References

N. Hooftman et al., A review of the European passenger car regulations-real driving emissions vs. local air quality, Renewable and Sustainable Energy Reviews, 86 (2018) 1–21.

L. Zhou, M. Bai and G. Sun, 3D heat transfer, lubrication and friction coupled study for piston ring-liner on diesel engines, J. of Mechanical Science and Technology, 33 (2) (2019) 939–953.

S. Lee, J. Kang and S. Park, Measurement and modeling of crank train friction in light-duty diesel engines, JUMST, 34 (2) (2020) 889–903.

K. Kim et al., Characterization of engine oil additive packages on diesel particulate emissions, J. of Mechanical Science and Technology, 34 (2) (2020) 931–939.

H. Jensen et al., Potential fuel savings of the controlled pendulum-slider pump, MTZ Worldwide, 71 (2) (2010) 26–30.

J. Y. Hwang et al., Development of two oil pumping system for automatic transmission, SAE Technical Paper 2014-01-1766 (2014).

D. Staley, B. Pryor and K. Gilgenbach, Adaptation of a variable displacement vane pump to engine lube oil applications, SAE Technical Paper 2007-01-1567 (2007).

F. Toyoda et al., Development of variable discharge oil pump, SAE Technical Paper 2008-01-0087 (2008).

D. M. Wang et al., Numerical modeling of vane oil pump with variable displacement, SAE Technical Paper 2012-01-0637 (2012).

E. Mucchi et al., On the wear and lubrication regime in variable displacement vane pumps, Wear, 306 (2013) 36–46.

D. Bach, T. Masselter and T. Speck, Damping of pressure pulsations in mobile hydraulic applications by the use of closed cell cellular rubbers integrated into a vane pump, J. of Bionic Engineering, 14 (2017) 791–803.

M. Köster and A. Fidlin, Variable displacement vane pump, part I: a minimal nonlinear model, Nonlinear Dynamics, 90 (2017) 1077–1089.

M. Rundo and R. Squarcini, Experimental procedure for measuring the energy consumption of IC engine lubricating pumps during a NEDC driving cycle, SAE Technical Paper 2009-01-1919 (2009).

M. Rundo and N. Nervegna, Lubrication pumps for internal combustion engines: a review, International Journal of Fluid Power, 16 (2) (2015) 59–74.

E. Frosina et al., A critical analysis on the lubrication circuit of a non-road diesel engine by adopting a 3D and 1D approaches, Energy Procedia, 81 (2015) 794–804.

H. Wittel et al., Roloff/Matek Maschinenelemente, 21st Ed., Springer Vieweg, Wiesbaden (2013).

Q. Xin, Friction and lubrication in diesel engine system design, Diesel Engine System Design, 1st Edition, Woodhead Publishing, Sawston (2013).

Acknowledgments

This work was supported by Research Program supported by the Natural Science Foundation of Zhejiang, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Zhongmin Liu is an Associate Professor of Mechanical Engineering, Hangzhou Dianzi University, Hangzhou, China. He received his Ph.D. in Mechanical Engineering from Zhejiang University. His research interests include engine lubrication, low friction of engine.

Rights and permissions

About this article

Cite this article

Liu, Z., Cheng, L. & Zhai, X. Experimental study on the oil pump driving energy consumption and lubrication safety in a PFI engine under NEDC and WLTC. J Mech Sci Technol 36, 457–465 (2022). https://doi.org/10.1007/s12206-021-1243-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-1243-3