Abstract

Artificial intelligence (AI) in machine tools offers diverse advantages, including learning and optimizing machining processes, compensating errors, saving energy, and preventing failures. Various AI techniques have been proposed and applied; however, many challenges still exist that inhibit the use of AI for machining tasks. This paper deals with different types and usage of AI technologies in machining operations such as predictive modelling, parameter optimization and control, chatter stability, tool wear, and energy conservation. We discuss the challenges of AI technologies, such as data quality, transferability, explainability, and suggest future directions to overcome them.

Similar content being viewed by others

References

R. Geissbauer, S. Schrauf, P. Berttram and F. Cheraghi, Digital Factories 2020 Shaping the Future of Manufacturing, Pricewaterhouse Coopers, Germany (2017).

M. Wetmore, Industry 4.0: an Opportunity to Shine for Canadian Manufacturers, Pricewaterhouse Coopers, Canada (2016).

A. Iqbal, G. Zhao, H. Suhaimi, N. He, G. Hussain and W. Zhao, Readiness of subtractive and additive manufacturing and their sustainable amalgamation from the perspective of Industry 4.0: a comprehensive review, The International Journal of Advanced Manufacturing Technology, 111 (2020) 2475–2498.

S. Jr. Kline, 2020 Capital Spending Machine Tools Survey, Gardner Intelligence, USA (2020).

H. Hassani, E. S. Silva, S. Unger, M. Tajmazinani and S. MacFeely, Artificial intelligence (AI) or intelligence augmentation (IA): what is the future, AI, 1 (2) (2020) 143–155.

J. Johnson, 4 Types of AI, BMC, Houston, Texas, USA (2020).

M. I. Jordan and T. M. Mitchell, Review-machine learning: trends, perspectives, and prospects, Science (Special Section: Artificial Intelligence), 349 (6245) (2015) 255–260.

K. Xia, C. Sacco, M. Kirkpatrick, C. Saidy, L. Nguyen, A. Kircaliali and R. Harik, A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces, and intelligence, Journal of Manufacturing Systems, 58 (B) (2021) 210–230.

M. Matulis and C. Harvey, A robot arm digital twin utilizing reinforcement learning, Computers and Graphics, 95 (2021) 106–114.

G. E. Hinton, S. Osindero and Y. Teh, A fast learning algorithm for deep belief nets, Neural Computation, 18 (7) (2006) 1527–1554.

D. H. Kim, T. J. Y. Kim, X. Wang, M. Kim, Y. J. Quan, J. W. Oh, S. H. Min, H. Kim, B. Bhandari, I. Yang and S. H. Ahn, Smart machining process using machine learning: A review and perspective on machining industry, International Journal of Precision Engineering and Manufacturing-Green Technology, 5 (2018) 555–568.

C. W. Chang, H. W. Lee and C. H. Liu, A review of artificial intelligence algorithms used for smart machine tools, Inventions, 3 (3) (2018) 41.

T. Wuest, D. Weimer, C. Irgens and K. D. Thoben, Machine learning in manufacturing: advantages, challenges, and applications, Production & Manufacturing Research, 4 (1) (2016) 23–45.

G. Seif, The 5 Clustering Algorithms Data Scientists Need to Know, Towards Data Science, Canada (2018).

L. Maaten and G. Hinton, Visualizing data using t-SNE, Journal of Machine Learning Research, 9 (2008) 2579–2605.

Y. Altintas, Manufacturing Automation, 2nd Ed., Cambridge University Press, New York, USA (2012).

H. Cherukuri, E. Perez-Bernabeu, M. Selles and T. Schmitz, Machining chatter prediction using a data learning model, Journal of Manufacturing Materials Processing, 3 (2) (2019) 45–59.

J. Karandikar, A. Honeycutt, T. Schmitz and S. Smith, Stability boundary and optimal operating parameter identification in milling using Bayesian learning, Journal of Manufacturing Processes, 56 (B) (2020) 1252–1262.

Y. Fu, Y. Zhang, H. Qiao, D. Li, H. Zhou and J. Leopold, Analysis of feature extracting ability for cutting state monitoring using deep belief networks, Procedia CIRP, 31 (2015) 29–34.

M. Lamraoui, M. Barak, M. Thomas and M. El Badoui, Chatter detection in milling machines by neural network classification and feature selection, Journal of Vibration and Control, 21 (7) (2015) 1251–1266.

Z. Yao, D. Mei and Z. Chen, On-line chatter detection and identification based on wavelet and support vector machine, Journal of Materials Processing Technology, 210 (5) (2010) 713–719.

M. Tran, M. Liu and Q. Tran, Milling chatter detection using scalogram and deep convolutional neural network, The International Journal of Advanced Manufacturing Technology, 107 (2020) 1505–1516.

D. Zhang, G. Bi, Z. Sun and Y. Guo, Online monitoring of precision optics grinding using acoustic emission based on support vector machine, International Journal of Advanced Manufacturing Technology, 80 (2015) 761–774.

Y. Dun, L. Zhu, B. Yan and S. Wang, A chatter detection method in milling of thin-walled TC4 alloy workpiece based on auto-encoding and hybrid clustering, Mechanical Systems and Signal Processing, 158 (2021) 107755.

M. C. Yesilli, F. A. Khasawneh and A. Otto, On transfer learning for chatter detection in turning using wavelet packet transform and ensemble empirical mode decomposition, CIRP Journal of Manufacturing Science and Technology, 28 (2020) 118–135.

L. T. Tunc, Smart tool path generation for 5-axis ball-end milling of sculptured surfaces using process models, Robotics and Computer-Integrated Manufacturing, 56 (2019) 212–221.

L. T. Tunc and M. Zatarain, Stability optimal selection of stock shape and tool axis in finishing of thin-wall parts, CIRP Annals, 68 (1) (2019) 401–404.

S. Chao and Y. Altintas, Chatter free tool orientations in 5-axis ball-end milling, International Journal of Machine Tools and Manufacture, 106 (2016) 89–97.

Y. Yuan, H. T. Zhang, Y. Wu, T. Zhu and H. Ding, Bayesian learning-based model-predictive vibration control for thin-walled workpiece machining processes, IEEE/ASME Transactions on Mechatronics, 22 (1) (2017) 509–520.

Q. Guo, J. Yang and H. Wu, Application of ACO-BPN to thermal error modeling of NC machine tool, The International Journal of Advanced Manufacturing Technology, 50 (5–8) (2010) 667–675.

J. Mayr, J. Jedrzejewski, E. Uhlmann, M. Alkan Donmez, W. Knapp, F. Härtig, K. Wendt, T. Moriwaki, P. Shore, R. Schmitt, C. Brecher, T. Würz and K. Wegener, Thermal issues in machine tools, CIRP Annals — Manufacturing Technology, 61 (2) (2012) 771–791.

J. Vyroubal, Compensation of machine tool thermal deformation in spindle axis direction based on decomposition method, Precision Engineering, 36 (1) (2012) 121–127.

B. Li, X. Tian and M. Zhang, Thermal error modeling of machine tool spindle based on the improved algorithm optimized BP neural network, The International Journal of Advanced Manufacturing Technology, 105 (1) (2019) 1497–1505.

H. Wang, L. Wang, T. Li and J. Han, Thermal sensor selection for the thermal error modeling of machine tool based on the fuzzy clustering method, The International Journal of Advanced Manufacturing Technology, 69 (1–4) (2013) 121–126.

M. Fujishima, K. Narimatsu, N. Irino, M. Mori and S. Ibaraki, Adaptive thermal displacement compensation method based on deep learning, CIRP Journal of Manufacturing Science and Technology, 25 (2019) 22–25.

C. H. Lo, J. Yuan and J. Ni, Optimal temperature variable selection by grouping approach for thermal error modeling and compensation, International Journal of Machine Tools and Manufacture, 39 (9) (1999) 1383–1396.

S. Yang, J. Yuan and J. Ni, The improvement of thermal error modeling and compensation on machine tools by CMAC neural network, International Journal of Machine Tools and Manufacture, 36 (4) (1996) 527–537.

C. Ma, L. Zhao, X. Mei, H. Shi and J. Yang, Thermal error compensation based on genetic algorithm and artificial neural network of the shaft in the high-speed spindle system, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 231 (5) (2017) 753–767.

C. Ma, L. Zhao, X. Mei, H. Shi and J. Yang, Thermal error compensation of high-speed spindle system based on a modified BP neural network, The International Journal of Advanced Manufacturing Technology, 89 (9–12) (2017) 3071–3085.

Y. Zhang, J. Yang and H. Jiang, Machine tool thermal error modeling and prediction by grey neural network, The International Journal of Advanced Manufacturing Technology, 59 (9–12) (2012) 1065–1072.

A. M. Abdulshahed, A. P. Longstaff, S. Fletcher and A. Potdar, Thermal error modelling of a gantry-type 5-axis machine tool using a grey neural network model, Journal of Manufacturing Systems, 41 (2016) 130–142.

K. C. Wang, P. C. Tseng and K. M. Lin, Thermal error modeling of a machining center using grey system theory and adaptive network-based fuzzy inference system, International Journal Series C Mechanical Systems, Machine Elements and Manufacturing, 49 (4) (2006) 1179–1187.

A. M. Abdulshahed, A. P. Longstaff and S. Fletcher, A cuckoo search optimisation-based Grey prediction model for thermal error compensation on CNC machine tools, Grey Systems: Theory and Application, 7 (2) (2017) 146–155.

P. Liu, Z. Du, H. Li, M. Deng, X. Feng and J. Yang, Thermal error modeling based on BiLSTM deep learning for CNC machine tool, Advanced Manufacturing, 9 (2021) 235–249.

W. Chengyang, X. Sitong and X. Wansheng, Spindle thermal error prediction approach based on thermal infrared images: a deep learning method, Journal of Manufacturing Systems, 59 (2021) 67–80.

K. Liu, L. Song, W. Han, Y. Cui and Y. Wang, Time-varying error prediction and compensation for movement axis of CNC machine tool based on digital twin, IEEE Transactions on Industrial Informatics, 18 (1) (2022) 109–117.

J. Liu, H. Gui and C. Ma, Digital twin system of thermal error control for a large-size gear profile grinder enabled by gated recurrent unit, Journal of Ambient Intelligence and Humanized Computing (2021).

Y. F. Li, X. X. Han and S. Y. Li, Non-contact dimension measurement of mechanical parts based on image processing, 8th International Congress on Image and Signal Processing (CISP), Shenyang, PRC (2015) 974–978.

K. Khalili and M. Vahidnia, Improving the accuracy of crack length measurement using machine vision, Procedia Technology, 19 (2015) 48–55.

Z. Wei, B. Zhang and P. Liu, Object dimension measurement based on mask R-CNN, 12th International Conference on Intelligent Robotics and Applications, Shenyang, PRC (4) (2019) 320–330.

S. P. Lo, An adaptive-network based fuzzy inference system for prediction of workpiece surface roughness in end milling, Journal of Materials Processing Technology, 142 (2003) 665–675.

W. H. Ho, J. T. Tsai, B. T. Lin and J. H. Chou, Adaptive network-based fuzzy inference system for prediction of surface roughness in end milling process using hybrid Taguchi-genetic learning algorithm, Expert Systems with Applications, 36 (2) (2009) 3216–3222.

Z. Jurkovic, G. Cukor, M. Brezocnik and T. Brajkovic, A comparison of machine learning methods for cutting parameters prediction in high speed turning process, Journal of Intelligent Manufacturing, 29 (2018) 1683–1693.

I. Svalina, G. Simunovic, T. Saric and R. Lujic, Evolutionary neuro-fuzzy system for surface roughness evaluation, Applied Soft Computing, 52 (2017) 593–604.

L. C. Moreira, L. D. Li, X. Lu and M. E. Fitzpatrick, Supervision controller for real-time surface quality assurance in CNC machining using artificial intelligence, Computers & Industrial Engineering, 127 (2019) 158–168.

R. H. Guerra, R. Quiza, A. Villalonga, J. Arenas and F. Castano, Digital twin-based optimization for ultraprecision motion systems with backlash and friction, IEEE Access, 7 (2019) 93462–93472.

G. Kant and K. S. Sangwan, Predictive modelling and optimization of machining parameters to minimize surface roughness using artificial neural network coupled with genetic algorithm, Procedia CIRP, 31 (2015) 453–458.

S. Wang, X. Lu, X. X. Li and W. D. Li, A systematic approach of process planning and scheduling optimization for sustainable machining, Journal of Cleaner Production, 87 (2015) 914–929.

J. Lipski and K. Zaleski, Implementation of artificial intelligence in optimization of technological processes, MATEC Web of Conferences, 252 (2019) 03008.

D. Karayel, Prediction and control of surface roughness in CNC lathe using artificial neural network, Journal of Materials Processing Technology, 209 (7) (2009) 3125–3137.

U. Zuperl, F. Cus and M. Reibenschuh, Modeling and adaptive force control of milling by using artificial techniques, Journal of Intelligent Manufacturing, 23 (5) (2012) 1805–1815.

U. Zuperl and F. Cus, Surface roughness fuzzy inference system within the control simulation of end milling, Precision Engineering, 43 (2016) 530–543.

E. Ülker, M. E. Turanalp and H. S. Halkaci, An artificial immune system approach to CNC tool path generation, Journal of Intelligent Manufacturing, 20 (1) (2009) 67–77.

H. El-Mounayri and H. Deng, A generic and innovative approach for integrated simulation and optimisation of end milling using solid modelling and neural network, International Journal of Computer Integrated Manufacturing, 23 (1) (2010) 40–60.

J. Balic and M. Korosec, Intelligent tool path generation for milling of free surfaces using neural networks, International Journal of Machine Tools and Manufacture, 42 (10) (2002) 1171–1179.

H. Ghaiebi and M. Solimanpur, An ant algorithm for optimization of hole-making operations, Computers & Industrial Engineering, 52 (2) (2007) 308–319.

A. T. Abbas, M. F. Aly and K. Hamza, Optimum drilling path planning for a rectangular matrix of holes using ant colony optimization, International Journal of Production Research, 49 (19) (2011) 5877–5891.

B. Li, H. Zhang, P. Ye and J. Wang, Trajectory smoothing method using reinforcement learning for computer numerical control machine tools, Robotics and Computer-Integrated Manufacturing, 61 (2020) 101847.

B. Denkena, E. Abele, C. Brecher, M. A. Dittrich, S. Kara and M. Mori, Energy efficient machine tools, CIRP Annals-Manufacturing Technology, 69 (2020) 646–667.

Okuma America Corporation, Energy-Efficient Machine Tool Technologies, For Any Size Shop [White paper], Charlotte, North Carolina, USA (2015).

A. Vijayaraghavan and D. Dornfeld, Automated energy monitoring of machine tools, CIRP Annals, 59 (1) (2010) 21–24.

G. Y. Zhao, Z. Y. Liu, Y. He, H. J. Cao and Y. B. Guo, Energy consumption in machining: classification, prediction, and reduction strategy, Energy, 133 (2017) 142–157.

N. Sihag and K. S. Sangwan, A systematic literature review on machine tool energy consumption, Journal of Cleaner Production, 275 (2020) 123125.

G. Kant and K. S. Sangwan, Predictive modelling for energy consumption in machining using artificial neural network, Procedia CIRP, 37 (2015) 205–210.

G. Zhao, Q. Zhao, G. Zheng and J. Zhai, Specific energy consumption prediction method based on machine tool power measurement, Sensors & Transducers, 174 (2014) 115–122.

X. Zhang, Q. Zhu, Y. He and Y. Xu, Energy modeling using an effective latent variable based functional link learning machine, Energy, 162 (2018) 883–891.

Z. Liu, X. Wang, Q. Zhang and C. Huang, Empirical mode decomposition based hybrid ensemble model for electrical energy consumption forecasting of the cement grinding process, Measurement, 138 (2019) 314–324.

R. Ak, M. M. Helu and S. Rachuri, Ensemble neural network model for predicting the energy consumption of a milling machine, Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, Massachusetts, USA (2015) 1–7.

Q. Xiao, C. Li, Y. Tang, Y. Du and Y. Kou, Deep learning based modeling for cutting energy consumed in CNC turning process, Proceedings of IEEE International Conference on Systems, Man, and Cybernetics, Miyazaki, Japan (2018) 1398–1403.

Z. W. Zhang, R. Z. Tang, T. Peng, L. Y. Tao and S. Jia, A method for minimizing the energy consumption of machining system: integration of process planning and scheduling, Journal of Cleaner Production, 137 (2016) 1647–1662.

D. Flum, J. Sossenheimer, C. Stück and E. Abele, Towards energy-efficient machine tools through the development of the twin-control energy efficiency module, M. Armendia, M. Ghassempouri, E. Ozturk, and F. Peysson (Eds.), Twin-Control, Springer, Cham, Switzerland (2019) 95–108.

The British Standards Institution, BS EN 13306, Maintenance — Maintenance Terminology, London, UK (2010).

M. Rausand and A. Hoyland, System Reliability Theory: Models, Statistical Methods, and Applications, John Wiley & Sons, Hoboken, New Jersey, USA, 396 (2003).

C. Okoh, R. Roy and J. Mehnen, Predictive maintenance modelling for through-life engineering services, Procedia CIRP, 59 (2017) 196–201.

G. W. Vogl, B. A. Weiss and M. Helu, A review of diagnostic and prognostic capabilities and best practices for manufacturing, Journal of Intelligent Manufacturing, 30 (1) (2019) 79–95.

C. Ly, K. Tom, C. S. Byington, R. Patrick and G. J. Vachtsevanos, Fault diagnosis and failure prognosis for engineering systems: a global perspective, 2009 IEEE International Conference on Automation Science and Engineering, Bengalore, India (2009) 108–115.

International Standards Organization, ISO 13381-1, Condition Monitoring and Diagnostics of Machines — Prognostics — Part 1: General Guidelines, Geneva, Switzerland (2004).

H. M. Elattar, H. K. Elminir and A. M. Riad, Prognostics: a literature review, Complex & Intelligent Systems, 2 (2) (2016) 125–154.

L. Liao and F. Köttig, Review of hybrid prognostics approaches for remaining useful life prediction of engineered systems, and an application to battery life prediction, IEEE Transactions on Reliability, 63 (1) (2014) 191–207.

H. Hanachi, W. Yu, I. Y. Kim, J. Liu and C. K. Mechefske, Hybrid data-driven physics-based model fusion framework for tool wear prediction, The International Journal of Advanced Manufacturing Technology, 101 (9) (2019) 2861–2872.

J. Caldeirani Filho and A. E. Diniz, Influence of cutting conditions on tool life, tool wear and surface finish in the face milling process, Journal of the Brazilian Society of Mechanical Sciences, 24 (2002) 10–14.

X. Cui, J. Zhao and Y. Dong, The effects of cutting parameters on tool life and wear mechanisms of CBN tool in high-speed face milling of hardened steel, The International Journal of Advanced Manufacturing Technology, 66 (5) (2013) 955–964.

D. A. Stephenson and J. S. Agapiou, Metal Cutting Theory and Practice, CRC Press, Boca Ranton, Florida, USA (2006).

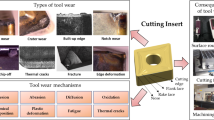

Y. Zhou and W. Xue, Review of tool condition monitoring methods in milling processes, The International Journal of Advanced Manufacturing Technology, 96 (5) (2018) 2509–2523.

G. Serin, B. Sener, A. M. Ozbayoglu and H. O. Unver, Review of tool condition monitoring in machining and opportunities for deep learning, The International Journal of Advanced Manufacturing Technology, 109 (3) (2020) 953–974.

Y. Zhang, K. Zhu, X. Duan and S. Li, Tool wear estimation and life prognostics in milling: Model extension and generalization, Mechanical Systems and Signal Processing, 155 (2021) 107617.

G. Xu, M. Liu, J. Wang, Y. Ma, J. Wang, F. Li and W. Shen, Data-driven fault diagnostics and prognostics for predictive maintenance: a brief overview, IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada (2019) 103–108.

Y. Lei, N. Li, L. Guo, N. Li, T. Yan and J. Lin, Machinery health prognostics: a systematic review from data acquisition to RUL prediction, Mechanical Systems and Signal Processing, 104 (2018) 799–834.

M. Liu, X. Yao, J. Zhang, W. Chen, X. Jing and K. Wang, Multi-sensor data fusion for remaining useful life prediction of machining tools by IABC-BPNN in dry milling operations, Sensors, 20 (17) (2020) 4657.

W. H. Hsieh, M. C. Lu and S. J. Chiou, Application of back-propagation neural network for spindle vibration-based tool wear monitoring in micro-milling, The International Journal of Advanced Manufacturing Technology, 61 (2012) 53–61.

S. Shankar, T. Mohanraj and R. Rajasekar, Prediction of cutting tool wear during milling process using artificial intelligence techniques, International Journal of Computer Integrated Manufacturing, 32 (2) (2019) 174–182.

Y. Zhou, B. Sun, W. Sun and Z. Lei, Tool wear condition monitoring based on a two-layer angle kernel extreme learning machine using sound sensor for milling process, Journal of Intelligent Manufacturing (2020).

R. Teti, K. Jemielniak, G. O’donnell and D. Dornfeld, Advanced monitoring of machining operations, CIRP Annals, 59 (2) (2010) 717–739.

M. Kuntoglu, A. Aslan, D. Y. Pimenov, U. A. Usca, E. Salur, M. K. Gupta, T. Mikolajczyk, K. Giasin, W. Kaplonek and S. Sharma, A review of indirect tool condition monitoring systems and decision-making methods in turning: critical analysis and trends, Sensors, 21 (1) (2021) 108.

B. Cuka and D. W. Kim, Fuzzy logic based tool condition monitoring for end-milling, Robotics and Computer-Integrated Manufacturing, 47 (2017) 22–36.

T. Mohanraj, S. Shankar, R. Rajasekar, N. R. Sakthivel and A. Pramanik, Tool condition monitoring techniques in milling process — a review, Journal of Materials Research and Technology, 9 (1) (2020) 1032–1042.

K. Zhu, Y. S. Wong and G. S. Hong, Wavelet analysis of sensor signals for tool condition monitoring: a review and some new results, International Journal of Machine Tools and Manufacture, 49 (7) (2009) 537–553.

D. D’Addona, T. Segreto, A. Simeone and R. Teti, ANN tool wear modelling in the machining of nickel superalloy industrial products, CIRP Journal of Manufacturing Science and Technology, 4 (1) (2011) 33–37.

R. H. L. da Silva, M. B. da Silva and A. Hassui, A probabilistic neural network applied in monitoring tool wear in the end milling operation via acoustic emission and cutting power signals, Machining Science and Technology, 20 (3) (2016) 386–405.

A. Gouarir, G. Martinez-Arellano, G. Terrazas, P. Bernados and S. Ratchev, In-process tool wear prediction system based on machine learning techniques and force analysis, Procedia CIRP, 77 (2018) 501–504.

W. Cai, W. Zhang, X. Hu and Y. Liu, A hybrid information model based on long short-term memory network for tool condition monitoring, Journal of Intelligent Manufacturing, 31 (2020) 1497–1510.

C. Zhang, X. Yao, J. Zhang and H. Jin, Tool condition monitoring and remaining useful life prognostic based on a wireless sensor in dry milling operations, Sensors, 16 (6) (2016) 795.

L. Xu, C. Huang, C. Li, J. Wang, H. Liu and X. Wang, Estimation of tool wear and optimization of cutting parameters based on novel ANFIS-PSO method toward intelligent machining, Journal of Intelligent Manufacturing, 32 (2021) 77–90.

A. J. Torabi, M. J. Er, X. Li, B. S. Lim and G. O. Peen, Application of clustering methods for online tool condition monitoring and fault diagnosis in high-speed milling processes, IEEE Systems Journal, 10 (2) (2016) 721–732.

P. Stavropoulos, A. Papacharalampopoulos, E. Vasiliadis and G. Chryssolouris, Tool wear predictability estimation in milling based on multi-sensorial data, The International Journal of Advanced Manufacturing Technology, 82 (2016) 509–521.

Q. Ren, L. Baron, M. Balazinski, R. Botez and P. Bigras, Tool wear assessment based on type-2 fuzzy uncertainty estimation on acoustic emission, Applied Soft Computing, 31 (2015) 14–24.

V. Pandiyan, W. Caeserendra, T. Tjahjowidodo and H. H. Tan, In-process tool condition monitoring in compliant abrasive belt grinding process using support vector machine and genetic algorithm, Journal of Manufacturing Processes, 31 (2018) 199–213.

B. Kaya, C. Oysu, H. M. Ertunc and H. Ocak, A support vector machine-based online tool condition monitoring for milling using sensor fusion and a genetic algorithm, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 226 (11) (2012) 1808–1818.

T. Benkedjouh, K. Medjaher, N. Zerhouni and S. Rechak, Health assessment and life prediction of cutting tools based on support vector regression, Journal of Intelligent Manufacturing, 26 (2) (2015) 213–223.

W. Li and T. Liu, Time varying and condition adaptive hidden Markov model for tool wear state estimation and remaining useful life prediction in micro-milling, Mechanical Systems and Signal Processing, 131 (2019) 689–702.

M. Elangovan, K. I. Ramachandran and V. Sugumaran, Studies on Bayes classifier for condition monitoring of single point carbide tipped tool based on statistical and histogram features, Expert Systems with Applications, 37 (3) (2010) 2059–2065.

S. Laddada, M. O. Si-Chaib, T. Benkedjouh and R. Drai, Tool wear condition monitoring based on wavelet transform and improved extreme learning machine, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 234 (5) (2019) 1057–1068.

W. Luo, T. Hu, Y. Ye, C. Zhang and Y. Wei, A hybrid predictive maintenance approach for CNC machine tool driven by digital twin, Robotics and Computer Integrated Manufacturing, 65 (2020) 101974.

H. Saglam, Tool wear monitoring in bandsawing using neural networks and Taguchi’s design of experiments, The International Journal of Advanced Manufacturing Technology, 55 (2011) 969–982.

D. Shi and N. Gindy, Tool wear predictive model based on least squares support vector machines, Mechanical Systems and Signal Processing, 21 (4) (2007) 1799–1814.

W. Caesarendra, T. Triwiyanto, V. Pandiyan, A. Glowacz, S. D. H. Permana and T. Tjahjowidodo, A CNN prediction method for belt grinding tool wear in a polishing process utilizing 3-axes force and vibration data, Electronics, 10 (12) (2021) 1429.

H. Oo, W. Wang and Z. Liu, Tool wear monitoring system in belt grinding based on image-processing techniques, The International Journal of Advanced Manufacturing Technology, 111 (2020) 2215–2229.

A. Kumar, R. B. Chinnam and F. Tseng, An HMM and polynomial regression based approach for remaining useful life and health state estimation of cutting tools, Computers & Industrial Engineering, 128 (2019) 1008–1014.

J. Dou, C. Xu, S. Jiao, B. Li, J. Zhang and X. Xu, An unsupervised online monitoring method for tool wear using a sparse auto-encoder, The International Journal of Advanced Manufacturing Technology, 106 (5) (2020) 2493–2507.

I. Goodfellow, Y. Bengio and A. Courville, Deep Learning, MIT Press, Cambridge, Massachusetts, USA (2016).

G. Press, Cleaning big data: most time-consuming, least enjoyable data science task, survey says, Forbes (2016).

C. Lin, T. Chen, L. Wang and H. Shuai, Health-based fault generative adversarial network for fault diagnosis in machine tools, Artificial Intelligence of Things Workshop in Association for the Advancement of Artificial Intelligence Conference, New York, USA (2020).

G. Chhabra, V. Vashisht and J. Ranjan, A review on missing data value estimation using imputation algorithm, Journal of Advanced Research in Dynamical and Control Systems, 11 (7) (2019) 312–318.

S. Han, H. J. Choi, S. K. Choi and J. S. Oh, Fault diagnosis of planetary gear carrier packs: A class imbalance and multi-class classification problem, International Journal of Precision Engineering and Manufacturing, 20 (2019) 167–179.

B. Roy, All About Feature Scaling, Towards Data Science, Canada (2020).

S. Shao, S. McAleer, R. Yan and P. Baldi, Highly accurate machine fault diagnosis using deep transfer learning, IEEE Transactions on Industrial Informatics, 15 (4) (2019) 2446–2455.

F. Yang, W. Zhang, L. Tao and J. Ma, Transfer learning strategies for deep learning-based PHM algorithms, Applied Sciences, 10 (7) (2020) 2361.

P. Cao, S. Zhang and J. Tang, Preprocessing-free gear fault diagnosis using small datasets with deep convolutional neural network-based transfer learning, IEEE Access, 6 (2018) 26241–26253.

R. Sawhney, Human in the Loop: Why We Will be Needed to Complement Artificial Intelligence, The London School of Economics and Political Science Business Review, London, UK (2018).

A. Widodo and B. S. Yang, Support vector machine in machine condition monitoring and fault diagnosis, Mechanical Systems and Signal Processing, 21 (6) (2007) 2560–2574.

J. Chen, P. Hu, H. Zhou, J. Yang, J. Xie, Y. Jiang, Z. Gao and C. Zhang, Toward intelligent machine tool, Engineering, 5 (4) (2019) 679–690.

Z. H. Zhou, Machine learning challenges and impact: an interview with Thomas Dietterich, National Science Review, 5 (1) (2018) 54–58.

Acknowledgements

This research was supported by the MSIT (Ministry of Science, ICT), Korea, under the High-Potential Individuals Global Training Program (2020-0-01529) supervised by the IITP (Institute for Information & Communications Technology Planning & Evaluation), and by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2018R1A2A1A05079477).

Author information

Authors and Affiliations

Corresponding author

Additional information

Simon S. Park is a Professor at the Schulich School of Engineering, Dept. of Mechanical and Manufacturing Engineering, University of Calgary, Canada. He was an AITF iCORE Chair in sensing and monitoring. He is a professional engineer in Alberta and is an associate member of CIRP (Int. Academy of Production Engineers) from Canada. Dr. Park received bachelor and master’s degrees from the University of Toronto, Canada. He then continued his Ph.D. at the University of British Columbia, Canada.

Rights and permissions

About this article

Cite this article

Chuo, Y.S., Lee, J.W., Mun, C.H. et al. Artificial intelligence enabled smart machining and machine tools. J Mech Sci Technol 36, 1–23 (2022). https://doi.org/10.1007/s12206-021-1201-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-1201-0