Abstract

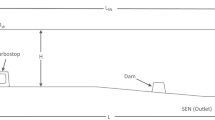

A moving weir to reduce the time for grade transition is proposed. To investigate benefits of the proposed moving weir, tundish flow subject to various conditions of a moving weir was numerically investigated. First, an optimal travelling path of a horizontally moving weir was determined in a water model. Investigation of various cases shows that the shortest transition time is obtained when new molten steel is injected after the weir returns to its original position after a round-trip. Using this travelling path, the speed of the moving weir was investigated in a real-scale model to determine an optimal speed that stabilizes the surface height while the transition time is minimized. As a result, intermixing of steel with dissimilar grades has been reduced by 14.5 % by using the optimal conditions of the moving weir. Lastly, the performance of vertically moving weirs was assessed by comparing with that of the horizontal counterpart.

Similar content being viewed by others

References

D. Mazumdar, Tundish metallurgy: towards increased productivity and clean steel, Transactions of the Indian Institute of Metals, 66(5–6) (2013) 597–610.

M. I. H. Siddiqui and M. H. Kim, Optimization of flow control devices to minimize the grade mixing in steelmaking tundish, J. of Mechanical Science and Technology, 32(7) (2018) 3213–3221.

Y. Sahai, Tundish technology for casting clean steel: a review, Metallurgical and Materials Transactions B, 47(4) (2016) 2095–2106.

J. Liu, H. Yan, L. I. U. Liu and X. Wang, Water modeling of optimizing tundish flow field, J. of Iron and Steel Research International, 14(3) (2007) 13–19.

M. Bensouici, A. Bellaouar and K. Talbi, Numerical investigation of the fluid flow in continuous casting tundish using analysis of RTD curves, J. of Iron and Steel Research International, 16(2) (2009) 22–29.

P. Ni, D. Wang, L. T. I. Jonsson, M. Ersson, T. Zhang and P. G. Jönsson, Numerical and physical study on a cylindrical tundish design to produce a swirling flow in the SEN during continuous casting of steel, Metallurgical and Materials Transactions B, 48(5) (2017) 2695–2706.

L. Zhang, S. Taniguchi and K. Cai, Fluid flow and inclusion removal in continuous casting tundish, Metallurgical and Materials Transactions B, 31(2) (2000) 253–266.

P. K. Jha, P. S. Rao and A. Dewan, Effect of height and position of dams on inclusion removal in a six strand tundish, ISIJ International, 48(2) (2008) 154–160.

V. Naderi, M. S. Nasrabadi and H. Arvanaghi, Effect of height of sharp-crested weir on discharge coefficient, International J. of Basic Science and Applied Research, 3 (2014) 325–330.

C. Chen, G. G. Cheng, H. B. Sun, X. C. Wang and J. Q. Zhang, Optimization of weir and dam with drain holes in continuous casting slab tundish, Advanced Materials Research, 476 (2012) 293–301.

A. K. Sinha and Y. Sahai, Mathematical modeling of inclusion transport and removal in continuous casting tundishes, ISIJ International, 33(5) (1993) 556–566.

H. Y. Chen and S. J. Huang, Adaptive neural network controller for the molten steel level control of strip casting processes, J. of Mechanical Science and Technology, 24(3) (2010) 755–760.

J. H. Son and I. S. Park, Prevention of air entrainment during liquid draining using disc-type vortex suppressor, J. of Mechanical Science and Technology, 32(10) (2018) 4675–4682.

C. W. Hirt and B. D. Nichols, Volume of fluid (VOF) method for the dynamics of free boundaries, J. of Computational Physics, 39(1) (1981) 201–225.

J. U. Brackbill, D. B. Kothe and C. A. Zemach, Continuum method for modeling surface tension, J. of Computational Physics, 100(2) (1992) 335–354.

P. Spalart and S. Allmaras, A one-equation turbulence model for aerodynamic flows, 30th Aerospace Sciences Meeting and Exhibit (1992) 439.

ANSYS FLUENT User’s Manual Version 15.0, ANSYS, Inc., Canonsburg, PA (2015).

Acknowledgments

This work was supported by POSCO under the Steel Science Project (2017Y011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Soohwan Jeon received his B.S. in Mechanical Engineering from Inha University. He is an integrated M.S./Ph.D. student at Pohang University of Science and Technology (POSTECH).

Sangseoung Lee received his B.S. and Ph.D. in Mechanical Engineering from Pohang University of Science and Technology. He is a Post-Doctoral Scholar at Pohang University of Science and Technology (POSTECH).

Sanghyun Ha received his B.S. in Pohang University of Science and Technology and is an integrated M.S./Ph.D. student at Pohang University of Science and Technology (POSTECH).

Sungjool Kim received his B.S. and M.S. in Mechanical Engineering from Busan National University. He is a Ph.D. student at Pohang University of Science and Technology and a researcher at POSCO.

Donghyun You is a Professor of Mechanical Engineering at Pohang University of Science and Technology (POSTECH).

Rights and permissions

About this article

Cite this article

Jeon, S., Lee, S., Ha, S. et al. Effects of a moving weir on tundish flow during continuous-casting grade-transition. J Mech Sci Technol 35, 4001–4009 (2021). https://doi.org/10.1007/s12206-021-0813-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0813-8