Abstract

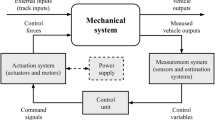

Common rail system is a key technology of energy saving and emission reduction for modern diesel engines. Multiple injection, as one of the most interesting features of common rail system, allows both optimal fuel consumption and exhaust emissions. In order to explore the method for controlling the fluctuation of fuel injection quantity during multiple injection, experiments have been carried out in this paper, focusing on pilot-main injection. The high pressure fuel circuits of the system have been equivalent to a spring-mass vibration system. Comparison with the experiment shows that the proposed fluctuation equation can reasonably predict the fluctuation characteristics of main injection quantity with pilot-main injection interval. The correction control strategy for the main injection quantity fluctuation has been proposed, in which the relative damping coefficient, rail pressure, pilot-main injection interval and main injection pulse width are chosen as the input variables. The experimental results with different rail pressure and main injection quantity show that the fluctuation of injection quantity during pilot-main injection can be controlled effectively by the proposed correction strategy. The maximum average fluctuation of main injection quantity decreases by as much as 44.66 %.

Similar content being viewed by others

References

M. A. Ismael, X. R. Heikal, X. R. A. Aziz, X. Syah and C. Crua, The effect of fuel injection equipment on the dispersed phase of water-in-diesel emulsions, Applied Energy, 222 (2018) 762–771.

Z. Feng, X. Zhan, X. Tang, X. Yang and Z. Huang, Experimental investigation on spray and atomization characteristics of diesel/gasoline/ethanol blends in high pressure common rail injection system, Energy, 112 (2016) 549–561.

K. Kim, X. Si, X. Jin, X. H. Kim, X. Cho, X. Baek and S. Park, Characterization of engine oil addictive packages on diesel particulate emissions, Journal of Mechanical Science and Technology, 34 (2) (2020) 931–939.

K. U. Rehman, X. Liu, X. Wang, X. Zheng, X. U. Rehman, X. Cheng and Z. Yu, Effects of black soldier fly biodiesel blended with diesel fuel on combustion, performance and emission characteristics of diesel engine, Energy Conversion and Management, 173 (2018) 489–498.

T. J. Wang, Effects of insulation on exhaust temperature and subsequent SCR efficiency of a heavy-duty diesel engine, Journal of Mechanical Science and Technology, 33 (2) (2019) 923–929.

A. K. Agarwal, X. Dhar, X. G. Gupta, X. I. Kim, X. Choi, X. S. Lee and S. Park, Effect of fuel injection pressure and injection timing of Karanja biodiesel blends on fuel spray, engine performance, emissions and combustion characteristics, Energy Conversion and Management, 91 (2015) 302–314.

C. S. Aalam, X. G. Saravanan and B. P. Anand, Impact of high fuel injection pressure on the characteristics of CRDI diesel engine powered by mahua methyl ester blend, Appl. Therm. Eng., 106 (2016) 702–711.

J. A. Soriano, X. Mata, X. Armas and C. Ávila, A zerodimensional model to simulate injection rate from first generation common rail diesel injectors under thermodynamic diagnosis, Energy, 158 (2018) 845–858.

S. H. Saraei and S. Khalilarya, Diesel combustion in heavy-duty engine with single- and double-injection strategies, Journal of Mechanical Science and Technology, 32 (4) (2018) 1889–1896.

M. R. Herfatmanesh and H. Zhao, Experimental investigation of hydraulic effects of two-stage fuel injection on fuel-injection systems and diesel combustion in a high-speed optical common-rail diesel engine, Int. J. Engine Res., 15 (1) (2014) 48–65.

A. P. Carlucci, X. Ficarella, X. Laforgia and L. Strafella, Improvement of dual-fuel biodiesel-producer gas engine performance acting on biodiesel injection parameters and strategy, Fuel, 209 (2017) 754–768.

F. Boudy and P. Seers, Impact of physical properties of bio-diesel on the injection process in a common-rail direct injection system, Energy Convers. Manag., 50 (12) (2009) 2905–2912.

D. Han, X. Duan, X. Wang, X. Lin, X. Huang and M. S. Wooldridge, Experimental study of the two-stage injection process of fatty acid esters on a common rail injection system, Fuel, 163 (2016) 214–222.

N. A. Henein, X. C. Lai, X. P. Singh, X. Zhong and J. Han, Characteristics of a common rail diesel injection system under pilot and injection modes, SAE Technical Paper (2002) 597–610.

L. Postrioti, X. Buitoni, X. C. Pesce and C. Ciaravino, Zeuch method-based injection rate analysis of a common-rail system operated with advanced injection strategies, Fuel, 128 (2014) 188–198.

M. R. Herfatmanesh, X. Peng, X. Ihracska, X. Lin, X. Lu and C. Zhang, Characteristics of pressure wave in common rail fuel injection system of high-speed direct injection diesel engines, Advances in Mechanical Engineering, 8 (5) (2016).

M. Badami, X. Millo and D. D. D’Amato, Experimental investigation on soot and NOx formation in a DI common rail diesel engine with pilot injection, SAE Technical Paper, Warrendale, PA (2001).

V. K. Gupta, X. Zhang and Z. Sun, Modeling and control of a novel pressure regulation mechanism for common rail fuel injection systems, Appl. Math. Model., 35 (7) (2011) 3473–3483.

G. M. Bianchi, X. Falfari, X. Brusiani, X. Pelloni, X. Osbat and M. Parotto, Numerical investigation of critical issues in multiple-injection strategy operated by a new CR fast-actuation solenoid injector, SAE Technical Paper (2005).

A. Ferrari and A. Mittica, Response of different injector typologies to dwell time variations and a hydraulic analysis of closely-coupled and continuous rate shaping injection schedules, Appl. Energy, 169 (2016) 899–911.

A. Ferrari, X. Paolicelli and P. Pizzo, Hydraulic performance comparison between the newly designed common feeding and standard common rail injection systems for diesel engines, J. Eng. Gas Turbines Power-Trans. Asme, 138 (9) (2016) 092801.

A. Ferrari, X. Paolicelli and P. Pizzo, The new-generation of solenoid injectors equipped with pressure-balanced pilot valves for energy saving and dynamic response improvement, Appl. Energy, 151 (2015) 367–376.

M. Chung, X. Kim, X. Kim, X. Sung and J. Lee, Effects of hydraulic flow and spray characteristics on diesel combustion in CR direct-injection engine with indirect acting Piezo injector, Journal of Mechanical Science and Technology, 29 (6) (2015) 2517–2528.

P. J. Gawthrop and G. P. Bevan, Bond-graph modeling, IEEE Control Syst. Mag., 27 (2) (2007) 24–45.

S. Birkett, X. Thoma and P. Roe, A pedagogical analysis of bond graph and linear graph physical system models, Math. Comput. Model. Dyn. Syst., 12 (2-3) (2006) 107–125.

M. Baratta, X. E. Catania and A. Ferrari, Hydraulic circuit design rules to remove the dependence of the injected fuel amount on dwell time in multijet CR systems, J. Fluids Eng., 130 (12) (2008) 121104.

B. D. Nikolić, B. Kegl, X. D. Marković and M. S. Mitrović, Determining the speed of sound, density and bulk modulus of rapeseed oil, biodiesel and diesel fuel, Thermal Science, 16 (2) (2012) 505–514.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (grant numbers NSFC 51809063, NSFC 51679048); China Postdoctoral Science Foundation (grant number 2018M630344); and Hei Long Jiang Postdoctoral Foundation (grant number LBH-Z18048).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Yong Tae Kang

Yun Bai received his B.S. degree in Engineering Mechanics from Shenyang Aerospace University, China in 2011. He received his Ph.D. in Power Engi-neering and Engineering Thermophysics from Harbin Engineering University, China in 2017. His research interests include modeling and simulation of diesel engine power plants, and optimization of diesel engines fuel injection system.

Rights and permissions

About this article

Cite this article

Bai, Y., Gu, Y., Lan, Q. et al. Correction strategy of fuel injection quantity during pilot-main injection for common rail system. J Mech Sci Technol 34, 2647–2656 (2020). https://doi.org/10.1007/s12206-020-0538-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0538-0