Abstract

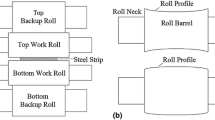

Hot rolling is performed inside a heating furnace where the material is heated above its recrystallization temperature. As pinch rolls are located in this furnace and subjected to continuous high temperature, they are typically cooled with water to protect them from the harmful effects of the high atmospheric temperature. Despite cooling, cracks can develop on the surface of water-cooled rolls, which can result in fracture over time; further, high-temperature oxidation can cause the metal strip to stick to the roll, resulting in defects on the strip surface. To address these problems, we analyzed pinch rolls through mechanical stress, thermal stress, and high-temperature oxidation investigations with data measured from a production line in situ. Subsequently, solutions for improving the performance of the pinch rolls predicted from the calculations were applied to an actual hot rolling process.

Similar content being viewed by others

References

B. Mintz, The influence of composition on the hot ductility of steels and to the problem of transverse cracking, ISIJ Int., 39 (9) (1999) 833–855.

R. Y. Chen and W. Y. D. Yeun, Review of the high-temperature oxidation of iron and carbon steels in air or oxygen, Oxid. Met., 59 (5-6) (2003) 433–468.

E. J. Patula, Steady-state temperature distribution in a rotating roll subject to surface heat fluxes and convective cooling, J. Heat Transfer, 103 (1) (1981) 36–41.

C. G. Kang and Y. D. Kim, Model experiments for the determination of the heat-transfer coefficient and transition thermal analysis in the direct rolling process, J. Mater. Process Technol., 84 (1-3) (1998) 210–224.

O. Kato, H. Yamamoto, M. Ataka and K. Nakajima, Mechanisms of surface deterioration of roll for hot strip rolling, ISIJ Int., 32 (11) (1992) 1216–1220.

R. D. Mercado-Solis, J. J. Talamantes-Silva, J. H. Beynon and M. A. L. Hernandez-Rodriguez, Modelling surface thermal damage to hot mill rolls, Wear, 263 (7-12) (2007) 1560–1567.

M. F. Rothman, Ferrous Alloys: High-temperature Property Data, ASM International (1988).

R. R. Craig Jr., Mechanics of Materials, 2nd Ed., Wiley, Hoboken, NJ, USA (2000) 229–257.

N. E. Dowling, Mechanical Behavior of Materials, 4th Ed., Pearson, London, UK (2012) 172–215.

G. E. Deiter, Mechanical Metallurgy SI Metric Edition, McGraw-Hill, NY, USA (1988) 3–183.

H.-J. Pyo, Mechanical Design, Theory and Practice, 6th Ed., Kyobobooks (2013) 57–172.

F. P. Incropera and D. P. DeWiff, Fundamentals of Heat and Mass Transfer, 5th Ed., Wiley, Hoboken, NJ, USA (2007) 4–546.

F. M. White, Fluid Mechanics, 6th Ed., McGraw-Hill, NY, USA (1999).

D. R. Gaskell, An Introduction to Transport Phenomena in Materials Engineering, Purdue University, West Lafayette, IN, USA (1992) 30–134.

P. Kofstad and R. Bredesen, High-temperature corrosion in metallic superficies, Proc. of Symposium on Fundamental Aspects of High Temperature Corrosion II, 86 (9) (1998) 141.

N. Birks, H. Meier and F. S. Pettit, Introduction to the High-Temperature Oxidation of Metals, 2nd Ed., Cambridge University Press, Cambridge, UK (2010).

D. R. Gaskell, Introduction to the Thermodynamics of Materials, 5th Ed., Taylor & Francis, Boca Raton, Florida (2008) 7–382.

D. A. Porter, K. E. Easterling and M. Y. Sherif, Phase Transformations in Metals and Alloys, 3rd Ed., Taylor & Francis, Boca Raton, Florida (2009) 1–63.

American Society of Mechanical Engineers, Boiler and Pressure Vessel Code. Section VIII, Rules for Construction of Pressure Vessels. Division 1-2, ASME Press (1983).

C. J. Noll and C. Lipson, Allowable working stress, society for experimental stress analysis, Proc. of Society for Experimental Stress Analysis, 3 (2) (1946) 29.

J. E. Shigley, C. R. Mischke and R. G. Budynas, Mechanical Engineering Design, 7th Ed., McGraw-Hill, NY, USA (2004) 3–124.

E. B. Haugen and P. H. Wirsching, Probabilistic Design, Machine Design, Penton Publishing, New York, USA, 47 (1975) 66–137.

R. Kuguel, A relation between theoretical stress concentration factor and fatigue notch factor deduced from the concept of highly stressed volume, Proc. ASTM, 61 (1961) 732–748.

Acknowledgments

This work was supported by a Korea Institute for Advancement of Technology grant, funded by the Korea Government (MOTIE) (P0002019), as part of the Competency Development Program for Industry Specialists.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Tae June Kang

Yong-Joon Lee is a doctoral candidate at the Department of Materials Science and Engineering, Seoul National University, Seoul, Korea. He received his B.S. in Materials Science and Engineering from Korea University, Seoul, Korea and his M.S. in Materials Science and Engineering from Seoul National University. He is currently a project leader at POSCO.

Kyung-Woo Yi is a Professor at the Department of Materials Science and Engineering, Seoul National University, Seoul, Korea. His doctorate is from Seoul National University.

Rights and permissions

About this article

Cite this article

Lee, YJ., Yi, KW. Alleviation of high-temperature oxidation and cracking of water-cooled roll for hot-rolling steel. J Mech Sci Technol 33, 5787–5796 (2019). https://doi.org/10.1007/s12206-019-1125-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1125-0