Abstract

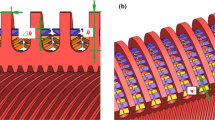

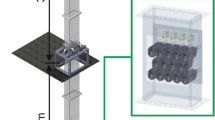

A novel manufacturing process for expanding the tubes of fin-tube type heat exchangers using a three-dimensional (3D) spiral expanding ball fabricated via metal additive manufacturing was proposed for the manufacture of highly efficient heat exchangers. To improve the heat transfer efficiency of fin-tube type heat exchangers, fine grooves are generally formed inside a tube to increase the heat transfer area. However, the height of a groove is commonly reduced when a tube is expanded for tightening with fins. To address this issue, a 3D expanding ball with spiral grooves was first developed and used in the expansion process. In conventional tube expansion, the height reduction of grooves is approximately 10.3 %. However, we demonstrated that it was dramatically improved, reaching approximately 1.7 %, when the proposed process with a 3D expanding ball was applied. We believe that this approach can be used in practical industries to manufacture highly efficient fin-tube heat exchangers.

Similar content being viewed by others

References

C. C. Wang, W. L. Fu and C. T. Chang, Heat transfer and friction characteristics of typical wavy fin and tube heat exchangers, Experimental Thermal and Fluid Science, 14 (2) (1997) 174–186.

K. Torii, K. M. Kwak and K. Nishino, Heat transfer enhancement accompanying pressure-loss reduction with winglet-type vortex generators for fin-tube heat exchangers, International Journal of Heat and Mass Transfer, 45 (2002) 3795–3801.

G. Biswas, N. K. Mitra and M. Fiebig, Heat transfer enhancement in fin-tube heat exchangers by winglet type vortex generators, International Journal of Heat and Mass Transfer, 37 (2) (1994) 283–291.

S. H. Kim, B. H. Ahn, J. M. Ha, Y. S. An and B. K. Choi, Structural and vibration analysis considering the flow velocity of the heat exchanger, International Journal of Precision Engineering and Manufacturing, 17 (6) (2016) 725–732.

K. J. Yong, B. C. Lim and S. H. Park, Heat flow analysis of inner groove tube for latent heat exchanger in condensing gas boiler, Journal of the Korea Academia-Industrial Cooperation Society, 15 (7) (2014) 4052–4056.

J. H. Yu, W. B. Bae, S. H. Park and H. S. Jeong, Structural design and manufacturing of corrugated plate for plate-type heat exchanger, Journal of the Korean Society for Precision Engineering, 33 (3) (2016) 199–205.

I. Muhammad, T. Khatoon, S. M. Ullah and T. J. Ko, Development of empirical model for biomachining to improve machinability and surface roughness of polycrystalline copper, International Journal of Precision Engineering and Manufacturing-Green Technology, 5 (2) (2018) 201–209.

C. C. Wnag, C. J. Lee, C. T. Chang and S. P. Lin, Heat transfer and friction correlation for compact louvered fin and tube heat exchangers, International Journal of Heat and Mass Transfer, 42 (11) (1999) 1945–1956.

F. Escanes, C. D. Perez-Segarra and A. Oliva, Numerical simulation of capillary tube expansion devices, International Journal of Refrigeration, 18 (2) (1995) 113–122.

D. Tang, T. Peng and D. Li, Numerical and experimental study on expansion forming of inner grooved tube, Journal of Materials Processing Technology, 209 (10) (2009) 4668–4674.

S. Lee, A. Ishibashi and T. Matusuda, Heat transfer characteristics of the non-uniform grooved tube considering tube expansion, International Refrigeration and Air Conditioning Conference, Indiana, U.S.A. (2014).

K. Bilen, M. Cetin, H. Hul and T. Balta, The investigation of groove geometry effect on heat transfer for internally grooved tubes, Applied Thermal Engineering, 29 (4) (2009) 753–761.

A. A. Ramadhan, Y. T. Anii and A. J. Shareef, Groove geometry effects on turbulent heat transfer and fluid flow, Heat and Mass Transfer, 49 (2) (2013) 185–195.

N.-H. Kim, J.-R. Cho and Y.-J. Ra, Structural integrity analysis and evaluation of cooled cooling air heat exchanger for aero engine, International Journal of Precision Engineering and Manufacturing, 19 (4) (2018) 529–535.

J. Kim, D. I. Hong and S. M. Kim, Study on the pool boiling heat transfer characteristics of aluminum plate with directional surface roughness, Journal of the Korean Society for Precision Engineering, 35 (5) (2018) 485–491.

T. J. An, S. W. Bae, D. S. Kim and J. Y. Kim, Study on the development and sintering process characteristics of powder bed fusion system, Journal of the Korean Society for Precision Engineering, 32 (9) (2015) 773–779.

Z. Y. Chua, I. H. Ahn and S. K. Moon, Process monitoring and inspection systems in metal additive manufacturing: Status and application, International Journal of Precision Engineering and Manufacturing-Green Technology, 4 (2) (2017) 235–245.

H. J. Lee, J. G. Song and D. G. Ahn, Investigation into the influence of feeding parameters on the formation of the fedpowder layer in a powder bed fusion (PBF) system, International Journal of Precision Engineering and Manufacturing, 18 (4) (2017) 613–621.

F. G. Guzman, M. Oezel, G. Jacobs, G. Burghardt, C. Broeckmann and T. Janitzky, Reproduction of white etching cracks under rolling contact loading on thrust bearing and two-disc test rigs, Wear, 390 (2017) 23–32.

Acknowledgments

This work was supported by the “Human Resources Program in Energy Technology” of the Korea Institute of Energy Technology Evaluation and Planning and granted financial resources by the Ministry of Trade, Industry, and Energy, Republic of Korea (No. 20184010201660). Furthermore, it was supported by the Basic Science Research Program through the National Research Foundation of Korea funded by the Ministry of Education (No. 2017R1D1A1A09000923).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Seok-min Kim

Seong Yeop Kang is a M.S. student in Pusan National University. His research interests include the development of manufacturing processes for heat exchangers and the optimal design of mechanical structures.

Sang Hu Park is a Professor in the School of Mechanical Engineering, Pusan National University. He obtained his M.A. and Ph.D. in Mechanical Engineering in the Korea Advanced Institute of Science and Technology in 1996 and 2006, respectively. His research fields include engineering for additive manufacturing, sheet metal forming, and nanofabrication.

Rights and permissions

About this article

Cite this article

Kang, SY., So, SR., Son, Y. et al. Three-dimensional fin-tube expansion process to achieve high heat transfer efficiency in heat exchangers. J Mech Sci Technol 33, 4401–4406 (2019). https://doi.org/10.1007/s12206-019-0836-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0836-6