Abstract

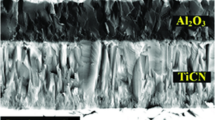

A recent trend on turning of difficult-to-machine (DTM) materials using environmentally friendly vegetable oil has became popular due to its immense machinability aids. Conventional cutting oils fail to give cooling/lubrication at higher cutting speed-feed combination and create environmental pollution. The present work investigated the effect of molybdenum disulphide nanoparticle (nMoS2) dispersed in castor oil, as a cutting fluid, sprayed using minimum quantity lubrication (MQL) technique on turning of AISI O1 cold worked tool steel. The machining was carried out by varying the speed ranging from 110–170 m/min, a feed rate of 0.02-0.08 mm/rev and depth of cut of 0.7 mm. PVD-TiAlN coated tungsten carbide insert was used for the experimentation. The experimental results of nMQL condition were compared with the dry and wet condition. The results proved that application nMQL has given 15–49 % enhanced tool life with better surface finish as compared with dry and wet condition, respectively. No major phase change occurs in nMQL when compared with other conditions because of their low cutting temperature.

Similar content being viewed by others

References

E. Kuram, B. Ozcelik and E. Demirbas, Environmentally friendly machining: Vegetable based cutting fluids, Green Manufacturing Processes and Systems (2013) 23–47.

B. Boswell, M. N. Islam, I. J. Davies, Y. R. Ginting and A. K. Ong, A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining, Int. J. Adv. Manuf. Technol., 92 (1–4) (2017) 321–340.

O. Çakir, A. Yardimeden, T. Ozben and E. Kilickap, Selection of cutting fluids in machining processes, J. Achievements in Mater. and Manuf. Engg., 25 (2007) 99–102.

J. Kundrák, A. G. Mamalis, K. Gyani and A. P. Markopoulos, Environmentally friendly precision machining, Mater. Manuf. Process., 21 (1) (2006) 29–37.

N. Boubekri, V. Shaikh and P. R. Foster, A technology enabler for green machining: minimum quantity lubrication (MQL), J. Manuf. Technol. Manag., 21 (5) (2010) 556–566.

M. Amrita, R. R. Srikant and A. V. Sitaramaraju, Performance evaluation of nanographite-based cutting fluid in machining process, Mater. Manuf. Process., 29 (5) (2014) 600–605.

H. Sohrabpoor, S. P. Khanghah and R. Teimouri, Investigation of lubricant condition and machining parameters while turning of AISI 4340, Int. J. Adv. Manuf. Technol., 76 (9–12) (2015) 2099–2116.

E. A. Rahim, M. R. Ibrahim, A. A. Rahim, S. Aziz and Z. Mohid, Experimental investigation of minimum quantity lubrication (MQL) as a sustainable cooling technique, Procedia CIRP, 26 (2015) 351–354.

S. Debnath, M. M. Reddy and Q. S. Yi, Environmental friendly cutting fluids and cooling techniques in machining: A review, J. Clean. Prod., 83 (2014) 33–47.

M. H. S. Elmunafi, N. M. Yusof and D. Kurniawan, Effect of cutting speed and feed in turning hardened stainless steel using coated carbide cutting tool under minimum quantity lubrication using castor oil, Adv. Mech. Eng., 7 (8) (2015) 1–7.

N. R. Dhar, M. T. Ahmed and S. Islam, An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel, Int. J. Mach Tools & Manufacture, 47 (2007) 748–753.

M. Hadad and B. Sadeghi, Minimum quantity lubrication-MQL turning of AISI 4140 steel alloy, J. Clean. Prod., 54 (2013) 332–343.

V. S. Sharma, M. Dogra and N. M. Suri, Cooling techniques for improved productivity in turning, Int. J. Mach.Tools. and Manuf., 49 (6) (2009) 435–453.

S. Ravi and M. P. Kumar, Experimental investigation of cryogenic cooling in milling of AISI D3 tool steel, Materials and Manufacturing Processes, 27 (2012) 1017–1021.

K. N. S. Ross and G. Manimaran, Effect of cryogenic coolant on machinability of difficult-to-machine Ni-Cr alloy using PVD-TiAlN coated WC tool, J. Braz. Soc. Mech. Sci. Eng., 41 (1) (2019) 44.

B. Li, C. Li, Y. Zhang, Y. Wang, D. Jia, M. Yang, N. Zhang, Q. Wu, Z. Han and K. Sun, Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil, J. Clean. Prod., 154 (2017) 1–11.

B. Rahmati, A. A. D. Sarhan and M. Sayuti, Investigating the optimum molybdenum disulfide (MoS2) nanolubrication parameters in CNC milling of AL6061-T6 alloy, Int. J. Adv. Manuf. Technol., 70 (5–8) (2014) 1143.

A. Karimi, M. A. A. Sadatlu, B. Saberi and H. M. Ashjaee, Experimental investigation on thermal conductivity of water based nickel ferrite nanofluids, Adv. Powder Technol., 26 (6) (2015) 1529–1536.

N. Saravanakumar, L. Prabu, M. Karthik and A. Rajamanickam, Experimental analysis on cutting fluid dispersed with silver nano particles, J. of Mechanical Science and Technology, 28 (2) (2014) 645–651.

A. K. Sharma, A. K. Tiwari, R. K. Singh and A. R. Dixit, Tribological investigation of TiO2 nanoparticle based cutting fluid in machining under minimum quantity lubrication (MQL), Mater. Today Proc., 3 (6) (2016) 2155–2162.

X.-Q. Wang and A. S. Mujumdar, Heat transfer characteristics of nanofluids: A review, Int. J. Therm. Sci., 46 (1) (2007) 1–19.

R. Padmini, P. V. Krishna and G. K. M. Rao, Effectiveness of vegetable oil base nanofluids as potential cutting fluids in turning AISI 1040 steel, Tribology International, 94 (2016) 490–501.

S. Kumar, D. Singh and N. S. Kalsi, Analysis of surface roughness during machining of hardened AISI 4340 steel using minimum quantity lubrication, Mater. Today Proc., 4 (2) (2017) 3627–3635.

B. Rahmati, A. Ahmed, D. Sarhan and M. Sayuti, Investigating the optimum molybdenum disulphide (MoS2) nanolubrication parameters in CNC milling of AL6061 — T6 alloy, Int. J. Adv. Manuf. Technol., 70 (5–8) (2014) 1143–1155.

A. Erdemir, Solid lubricants and self-lubricating films, Modern Tribology Handbook, CRC Press LLC (2001) Chapter 22.

ASTM E975-03, Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation, ASTM International, West Conshohocken, PA (2003).

T. Hahn and P. Paufler, International tables for crystallography, Vol A: Space-group symmetry D, Reidel Publ. Co., Dordrecht, Holland/Boston, U. S. A., 1983, 854 Seiten, Cryst. Res. Technol., 19 (10) (1984) 1306.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Seok-min Kim

V. Sivaraman is an Associate Professor in Mechanical Engineering. His main areas of interest are machining, hard turning, minimum quantity lubrication, optimization methodologies and artificial intelligence tools.

S. Prakash has been working at Sathyabama Institute of Science and Technology as Dean at School of Mechanical Engineering. His current areas of research are composite materials, wood composites, natural fibers, material characterization, etc.

Rights and permissions

About this article

Cite this article

Sivaraman, V., Prakash, S. Performance and evaluation of MoS2 based machining using PVD-TiAlN coated tool. J Mech Sci Technol 33, 4383–4388 (2019). https://doi.org/10.1007/s12206-019-0834-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0834-8