Abstract

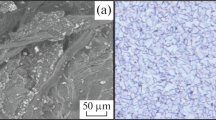

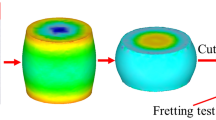

Fretting wear characteristics of Inconel X-750 were investigated under the dry test condition. Ball-on-flat contact configuration was subjected to the oscillatory movement at different sliding amplitudes through the different time duration and normal loading. Fretting tests were carried out according to the American Society for Testing and Materials standards (ASTM D6425) by the high frequency linear-oscillation wear test rig SRV 4 at room temperature with ∼60 % relative humidity. Worn surface morphologies in the case of stick, partial slip and gross slip regimes were examined by 3D optical profiler, scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The aim of this research is to study the tribological characteristics of the Ni-based Inconel X-750 superalloy, which is widely used in the air lubricated gas foil bearing applications where contacting surfaces are subjected to fretting motion. It is found that the displacement amplitude and normal load had strong effect on the fretting mode and damage mechanism. Wear mechanisms were associated with the plastically sheared asperities and crack nucleation and propagation during the stick and partial slip regimes, respectively. As the displacement increased, the wear modes were switched to adhesion, abrasion, debris oxidation, delamination and plastic deformation during the gross slip condition. Fretting time dependence was critical in the higher displacement amplitudes where the wear volume loss progressed significantly. However, test duration was less consistent in the stick and partial slip regimes where the wear properties remains unchanged over time.

Similar content being viewed by others

References

Z. R. Zhou, S. Fayeulle and L. Vincent, Cracking behaviour of various aluminium alloys during fretting wear, Wear, 155(2) (1992) 317–330.

L. Vincent, Y. Berthier, M. C. Dobourg and M. Godet, Mechanics and materials in fretting, Wear, 153(1) (1992) 135–148.

R. D. Mindlin, Compliance of elastic bodies in contact, Journal of Applied Mechanics, 16 (1949) 259–268.

Z. R. Zhou and L. Vincent, Mixed fretting regime, Wear, 181 (1995) 531–536.

S. Fouvry, P. Kapsa, Z. Hassan and L. Vincent, Wear analysis in fretting of hard coatings through a dissipated energy concept, Wear, 203 (1997) 393–403.

G. W. Stachowiak, Wear: Materials, Mechanisms and Practice, John Wiley & Sons (2006).

G. Stachowiak and G. W. Stachowiak, Fretting wear and friction behaviour of engineering ceramics, Wear, 190(2) (1995) 212–218.

N. Ohmae and T. Tsukizoe, The effect of slip amplitude on fretting, Wear, 27(3) (1974) 281–294.

L. Toth, The investigation of the steady stage of steel fretting, Wear, 20(3) (1972) 277–286.

M. L. Lewis and P. Didsbury, The rubbing fretting behaviour of mild steel in air at room temperature: The effect of load, frequency, slip amplitude and test duration, Treatise on Materials Science and Technology, Wear, Academic Press New York, 13 (1979).

O. Vingsbo and S. Söderberg, On fretting maps, Wear, 126(2) (1988) 131–147.

J. Vižintin, M. Kalin, S. Novak, G. Drazic, L. K. Ives and M. B. Peterson, Effect of slip amplitude on the fretting wear of silicon nitride against silicon nitride, Wear, 192(1–2) (1996) 11–20.

R. F. Baker and A. V. Olver, Direct observations of fretting wear of steel, Wear, 203 (1997) 425–433.

P. De Baets, K. Strijckmans and A. P. Van Peteghem, Characterisation of the fretting wear of unlubricated steel surfaces based on the comparison of wear results obtained by different methods, Wear, 208(1–2) (1997) 169–176.

G. X. Chen and Z. R. Zhou, Study on transition between fretting and reciprocating sliding wear, Wear, 250(1–12) (2001) 665–672.

J. Li and Y. H. Lu, Effects of displacement amplitude on fretting wear behaviors and mechanism of Inconel 600 alloy, Wear, 304(1–2) (2013) 223–230.

X. Long, W. Zihao, L. Jie, L. Yonghao and S. Tetsuo, Microstructural characterization of subsurface caused by fretting wear of Inconel 690TT alloy, Materials Characterization, 115 (2016) 32–38.

W. Qiufeng, W. Yunxia, W. Hongling, F. Na and Y. Fengyuan, Experimental investigation on tribological behavior of several polymer materials under reciprocating sliding and fretting wear conditions, Tribology International, 104 (2016) 73–82.

E. Liu, B. Blanpain and J. P. Celis, Fretting friction and wear of polycrystalline diamond coatings, Diamond and Related Materials, 5(6–8) (1996) 649–653.

D. Dongxing, L. Daoxin, Y. Zuoyan, Z. Xiaohua, L. Fanqiao, Z. Ziqi and Y. Lei, Fretting wear and fretting fatigue behaviors of diamond-like carbon and graphite-like carbon films deposited on Ti-6Al-4V alloy, Applied Surface Science, 313 (2014) 462–469.

D. Wenbo, S. Yanhua, D. Chunhua and Y. Lie, Structural stiffness of X-750 alloy bump foil strips for compliant foil bearings with different heat treatments, Journal of Tribology, 138(3) (2016) 031702.

J. S. Larsen, A. C. Varela and F. S. Ilmar, Numerical and experimental investigation of bump foil mechanical behaviour, Tribology International, 74 (2014) 46–56.

S. Fouvry, P. Kapsa and L. Vincent, Quantification of fretting damage, Wear, 200(1–2) (1996) 186–205.

N. Diomidis and S. Mischler, Third body effects on friction and wear during fretting of steel contacts, Tribology International, 44(11) (2011) 1452–1460.

H. Bingbing, O. Huajiang, H. Shangwen and R. Xingmin, Stick-slip vibration of a friction damper for energy dissipation, Advances in Mechanical Engineering, 9(7) (2017) 1–13.

V. K. Virendra, N. S. Hamza, S. R. Ganesh, H. Murthy, N. M. Anuradha and D. F. Chandru, Effect of contact pressure and stress ratio on the fretting fatigue behaviour of Ti-6Al-4 V, Materials Science & Engineering, 707 (2017) 647–656.

C. Park, J. Kim, A. Sim, I. Park, H. Jang and E.-J. Chun, Influence of high-power diode laser heat treatment on wear resistance of a mold steel, Journal of Mechanical Science and Technology, 33(2) (2019) 829–836.

X. Long, L. Huijuan, H. Junling, L. Yonghao and S. Tetsuo, Damage mechanism of alloy 690TT mated with type 304 stainless steel during fretting wear in partial slip regime, Materials Characterization, 132 (2017) 284–292.

Z. R. Zhou, K. Nakazawa, M. H. Zhu, N. Maruyama, P. Kapsa and L. Vincent, Progress in fretting maps, Tribology International, 39(10) (2006) 1068–1073.

J. Yu, Z. B. Cai, M. H. Zhu, S. X. Qu and Z. R. Zhou, Study on torsional fretting behavior of UHMWPE, Applied Surface Science, 255(2) (2008) 616–618.

G. C. Wood and B. Chattopadhyay, Transient oxidation of Ni-base alloys, Corrosion Science, 10(7) (1970) 471–480.

M. H. Zhu and Z. R. Zhou, On the mechanisms of various fretting wear modes, Tribology International, 44(11) (2011) 1378–1388.

Y. Berthier, Background on Friction and Wear: Handbook of Materials Behaviour Models, Lemaître Academic Press, 8 (2001) 676–699.

I. Iordanoff, B. Seve and Y. Berthier, Solid third body analysis using a discrete approach: Influence of adhesion and particle size on macroscopic properties, Journal of Tribology, 124(3) (2002) 530–538.

L. Jie, L. Yonghao, Z. Haoyang and X. Long, Effect of grain size and hardness on fretting wear behavior of Inconel 600 alloys, Tribology International, 81 (2015) 215–222.

H. Mohrbacher, J. P. Celis and J. R. Roos, Laboratory testing of displacement and load induced fretting, Tribology International, 28(5) (1995) 269–278.

G. Xianglong, L. Ping, T. Lichen, W. Jiamei and Z. Lefu, Effects of sliding amplitude and normal load on the fretting wear behavior of alloy 690 tube exposed to high temperature water, Tribology International, 116 (2017) 155–163.

Acknowledgments

This work was supported by the National Key R&D Program of China (No. 2018YFB2000100), National Natural Science Foundation of China (No. 51735006), Aeronautical Science Fund of China (No. 20164058002), and Tsinghua University Initiative Scientific Research Program. The first author would like to acknowledge the scholarship support from China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Tae June Kang

Ibrohim Rustamov is currently Ph.D. candidate in the Dept. of Mech. Eng. at Tsinghua University, China. His research field involves fretting wear and heat treatment/surface modifications of nickel based alloys for gas foil bearing applications.

Fei Guo received his Ph.D. degree from the Dept. of Mech. Eng., Tsinghua University, China, in 2014 and joined the department in 2016. His research interests include the fields of fluid sealing, water lubrication and tribology.

Zixi Wang received his Ph.D. degree from the Dept. of Infor. Sys. and Telecom., Bauman Moscow State Technical University, Russia, in 2002. He is now Associate Researcher in Dept. of Mech. Eng., Tsinghua University, China. He is involved in the research of high-rotating bearing applications.

Rights and permissions

About this article

Cite this article

Rustamov, I., Guo, F. & Wang, Z. Experimental investigations into fretting wear and damage mechanisms of Inconel X-750 alloy. J Mech Sci Technol 33, 4701–4713 (2019). https://doi.org/10.1007/s12206-019-0818-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0818-8