Abstract

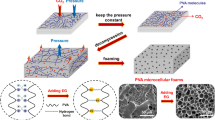

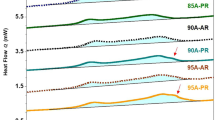

This study was carried out to investigate the morphological changes of polymers when the volume expansion of polymer-gas mixtures is suppressed. The polycarbonate-CO2 mixture specimens used in the experiments were prepared using a pressure vessel used in the batch foaming process. The foaming was carried out in an oil bath, which does not inhibit volume expansion, and in constant volume foaming equipment, which is specially designed to suppress volume expansion. Experiment results confirmed that the foaming temperature increased when the volume expansion of the specimens was suppressed. As the volume expansion of the specimens decreased, their foaming rate also declined relative to the oil bath. These phenomena can be explained by the fact that the volume expansion of the specimens during foaming was suppressed by the cavity of the constant volume foaming equipment. Moreover, external pressure was applied to the specimens, and pressure gradient was observed in the polymer.

Similar content being viewed by others

References

M. Frounchi, A. Sharif-Pakdaman, S. A. Mousavi and S. Dadbin, Polypropylene foaming in a reactive process, Journal of Cellular Plastics, 43 (2007) 445.

W.-C. V. Wang and E. J. Kramer, Effect of high-pressure CO2 on the glass transition temperature and mechanical properties of polystyrene, J. Polym. Sci. Polym. Phys., 20 (8) (1982) 1371–1384.

P. Le Parlouer and C. Dalmassone, Characterisation of gas hydrates forming using a new high pressure micro-DSC, Journal of Thermal Analysis and Calorimetry, 78 (2004) 165–172.

S. N. Leung, A. Wong, Q. Guo, C. B. Park and J. H. Zong, Change in the critical nucleation radius and its impact on cell stability during polymeric foaming process, Journal of Chemical Engineering Science (2009) 4899–4907.

R. Pop-IIiev, N. Dong, D. Xu and C. B. Park, Visualization of the foaming mechanism of polyethylene blown by chemical blowing agents under ambient pressure, Advances in Polymer Technology, 26 (2007) 213–222.

J. S. Colton and N. P. Suh, The nucleation of microcellular thermoplastic foam with additive, Polymer Engineer & Science, 27 (1987) 85–492.

C. B. Park and L. K. Cheung, A study of cell nucleation in the extrusion of polypropylene foams, Polym. Eng. Sci., 37 (1) (1997).

T. H. Chong and Y. W. Ha, Effect of dissolved gas on the viscosity of HIPS in the manufacture of microcellular plastics, Polymer Engineering & Science, 43 (6) (2004) 7 APR.

Acknowledgments

This research was supported by the Basic Science Research Program via the National Research Foundation of Korea (NRF), which is funded by the Ministry of Education (No. NRF-2018R1D1A1B07049405).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Seok-min Kim

Sung Woon Cha is a Professor of Mechanical Engineering at Yonsei University, Seoul, Korea. He received his Ph.D. in Mechanical Engineering from the Massachusetts Institute of Technology, USA, in 1994.

Rights and permissions

About this article

Cite this article

Lee, J., Sohn, J.S., Ryu, Y. et al. Suppression of cell creation through control of volume expansion. J Mech Sci Technol 33, 4407–4411 (2019). https://doi.org/10.1007/s12206-019-0743-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0743-x