Abstract

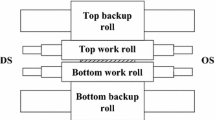

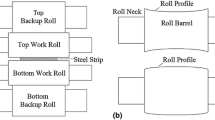

A hot rolling operation is performed to alter the thickness of a metal by passing the material through a pair of rollers, forming a gap that is somewhat narrower than the thickness of the material. Therefore, the quality of the product is a function of the pressure applied by the rollers. However, in this process, a roll hunting force occurs in which the rolling force is irregularly changed during the rotation of the rollers due to various complex mechanisms, which include roll surface hardness, difference in rotational speed between rolls, heat treatment conditions, and roll wear. In this study, roll wear tests were conducted to analyze the roll hunting force caused by variation in the hardness of the work roll. The friction coefficient of the work roll was then examined based on hardness. Then, a two-dimensional finite element model was constructed to investigate the roll hunting force as a function of the change in friction coefficient of the work roll. This finite element model was verified in relation to the theoretical rolling expression. Finite element model analysis was performed for three friction coefficients, and the effect of the roll hunting force was determined based on the reduction ratio and temperature. In addition, the wear depth of the work roll by the hardness was predicted. The influence of the abrasion of the work roll on the hunting force was analyzed.

Similar content being viewed by others

References

F. Hollander, A model to calculate the complete temperature distribution in steel during hot rolling, J. Iron Steel Inst., 208 (1970) 46–74.

C. Devadas and I. V. Samarasekara, Heat transfer during hot rolling of steel strip, Ironmak. Steelmak., 13 (1986). 311–321.

W. C. Chen, I. V. Samarasekara, A. Kumar and E. B. Haw-bolt, Mathematical modelling of heat flow and deformation during rough rolling, Ironmak. Steelmak., 20 (1993) 113–125.

X. Duan and T. Sheppard, Three dimensional thermal mechanical coupled simulation during hot rolling of aluminium alloy 3003, International Journal of Mechanical Sciences, 44(10) (2002) 2155–2172.

M. A. Cavaliere, M. B. Goldschmit and E. N. Dvorkin, Finite element analysis of steel rolling processes, Computers & Structures, 79 (22–25) (2001). 2075–2089.

Z. Y. Jiang and A. K. Tieu, Elastic-plastic finite element method simulation of thin strip with tension in cold rolling, Journal of Materials Processing Technology, 130–131 (2002). 511–515.

K. Linghu, Z. Jiang, J. Zhao, F. Li, D. Wei, J. Xu, X. Zhang and X. Zhao, 3D FEM analysis of strip shape during multipass rolling in a 6-high CVC cold rolling mill, Int. J. Adv. Manuf. Technol., 74 (2014) 1733–1745.

S. Y. Yuan, L. W. Zhang, S. L. Liao, G. D. Jiang, Y. S. Yu and M. Qi, Simulation of deformation and temperature in multi-pass continuous rolling by three-dimensional FEM, Journal of Materials Processing Technology, 209(6) (2009) 2760–2766.

J.-Y. Jung and Y.-T. Im, Improve of rolling load prediction with consideration of spread in hot rolling, J. KSME(A), 24(11) (2000) 2836–2844.

P. Munther and J. G. Lenard, Tribology during hot, flat rolling of steels, CIRP Annals-Manufacturing Technology, 44 (1995) 213–216.

W.-J. Kwak and S.-M. Hwang, Evaluation of model equation predicting roll force and roll power during hot rolling, Kor. Soc. Technol. Plast. (1999). 265–268.

K. H. Ziehenberger and M. Windhager, Sate of the art work rolls for hot rolling flat products, 3 rd Steel Industry Conference and Exposition (2007).

S. Shida, Empirical formula for flow stress of carbon steels - resistance to deformation of carbon steels at elevated temperatures 2nd report, J. Jpn. Soc. Tech. Plast., 10 (103) (1968–1969). 610–617.

A. L. Tselikov, G. S. Nikitin and S. E. Rokotyan, The Theory of Lengthwise Rolling, Mir (1981).

W. F. Hosford and R. M. Caddell, Metal Forming: Mechanics and Metallurgy, Prentice-Hall (2007).

R. B. Sims, The calculation of roll force and torque in hot rolling mills, Proc Inst. Mech. Eng., 168 (1954). 191–200.

P. M. Cook and A. W. McCrum, The Calculation of Load and Torque in Hot Flat Rolling, BISRA (1958).

S. Ekelund, Steel, 93, Weekly issues for 21 Aug. to 2 Oct (1933).

J. F. Achard, Contact and rubbing of flat surfaces, J. Appl. Phys., 24 (1953) 981–988.

A. Pesin, D. Pustovoytov and N. Lokotunina, Modeling of the roll wear and material damage during high - ratio differential speed rolling of aluminumalloy 7075, MATEC Web of Conferences, EDP Sciences (2016) 4006.

Acknowledgments

The study was supported by research funds from the hyundai steel institute and Human Resources Program in Energy Technology of the Korea Institute of Energy Technology Evaluation and Planning (KETEP), granted financial resource from the Ministry of Trade, Industry & Energy, Republic of Korea. (Grant No. 20194010201790).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Maenghyo Cho.

Hun Bong Lim received his master’s degree in mechanical design and mechatronics from Hanyang University, Korea. He is currently writing his Ph.D. thesis on structural vibration analysis of hot rolling mill. His research interests are related to structural dynamic analysis and plastic analysis.

Hyun Ik Yang is a Full Professor in the Hanyang University, Korea. He received the M.S and Ph.D. degrees in mechanical engineering from the Columbia University, USA. His main research interests are mechanical system design, optimum design/CAE, automatic finite element mesh generation, and energy conversion.

Chang Wan Kim received his Ph.D. in aerospace and engineering mechanics from the University of Texas at Austin, USA. He is currently an Associate Professor in School of Mechanical Engineering at Konkuk University, Korea. His research interests are in the field of paralleling computing on large scale vehicle noise and vibration (NVH) with FEM.

Rights and permissions

About this article

Cite this article

Lim, H.B., Yang, H.I. & Kim, C.W. Analysis of the roll hunting force due to hardness in a hot rolling process. J Mech Sci Technol 33, 3783–3793 (2019). https://doi.org/10.1007/s12206-019-0721-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0721-3