Abstract

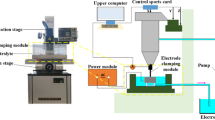

The micro-structure/parts of single crystal nickel-based superalloy materials are extensively used in high temperature environments. The recrystallization mechanism of the machined workpiece sub-surface is explained through energy storage model. A micro-milling experiment of single crystal nickel-based superalloy DD98 was performed by simulating the working environment at high temperature and setting different heat treatment temperature. By scanning electron microscopy (SEM), the influence of sub-surface structural elements on the properties of micro-milling workpiece was analyzed. Experimental results indicate that the recrystallization layer thickness of single crystal nickel-based superalloy DD98 increases with the increase of heat treatment temperature. When this temperature is between 950 °C and 1150 °C, the recrystallization thickness is 5–20 μm. The recrystallization of sub-surface layer takes the form of equiaxed recrystallization. Those provide basic data for restraining recrystallization of single crystal materials and have good scientific significance.

Similar content being viewed by others

References

N. Li et al., Progress in alloy design of nickel-based superalloys, Materials Review, 28(3) (2014) 1–6, 16.

X. Jiuhua, Z. Zhiwei and F. Yucan, Review and prospect on high efficiency profile grinding of nickel-based superalloys, Acta Aeronautica ET Astronautica Sinica, 35(2) (2014) 351–360.

G. Qi et al., Experimental study of micro-milling mechanism and surface quality of a nickel-based single crystal superalloy, J. of Mechanical Science and Technology, 31(1) (2017) 171–180.

K. Isomura et al., Development of micro-turbo charger and micro-combustor as feasibility studies of three-dimensional gas turbine at micro-scale, ASME Turbo Expo 2003, Collocated with the 2003 International Joint Power Generation Conference (2003) 3–26.

J. P. Davim, Modern Mechanical Engineering, Springer Berlin Heidelberg (2014).

C. Y. Jo and H. M. Kim, Effect of recrystallisation on microstructural evolution and mechanical properties of single crystal nickel based superalloy CMSX-2 Part 2-Creep behaviour of surface recrystallised single crystal, Metal Science J., 19(12) (2003) 1671–1676.

R. Burgel, P. D. Portella and J. Preuhs, Recrystallization in single crystals of nickel base superalloy, Superalloys (2000).

D. G. Thakur, B. Ramamoorthy and L. Vijayaraghavan, Some investigations on high speed dry machining of aerospace material inconel 718 using multicoated carbide inserts, Advanced Manufacturing Processes, 27(10) (2012) 1066–1072.

U. Attanasio et al., Tool wear effects on white and dark layer formation in hard turning of AISI 52100 steel, Wear, 286(7) (2012) 98–107.

Z. Bing, J. Tao and T. Chun-hu, Recrystallization of directionally solidified and single crystal superalloys, Failure Analysis and Prevention, 6(1) (2011) 56–64.

B. Zhang, C. Liu and J. Zhou, Dynamic recrystallization of single-crystal nickel-based super alloy, Transactions of Nonferrous Metals Society of China, 24(6) (2014) 1744–1749.

X. Jichun, L. Jiarong and Z. Jinqian, Characteristic and formation mechanism of precipitates at recrystallization grain boundaries of single crystal, Acta Metallurgical Sinica, 45(10) (2009) 1232–1236.

W. Wen-juan, T. Hai-jun and F. Qiang, Effects of surface treatment on cellular recrystallization of a second-generation single crystal superalloy, J. of Materials Engineering, 1(8) (2011) 42–47.

Z. L. Li et al., Plastic deformation and recrystallization of a Ni-based single crystal super alloy, Materials Science Forum, 850 (2016) 47–55.

J. R. Li, J. C. Xiong and D. Z. Tang, Advanced High Temperature Structural Materials and Techniques, Defense Industry Press (2012).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51375082) and the Doctoral Start-up Fund of Liaoning University of Technology (XR2018003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Yongho Jeon

Qi Gao is an Associate Professor at Liaoning University of Technology. He received a doctorate in mechanical engineering from Northeastern University. His research interests include micro precision process, digital manufacturing.

Rights and permissions

About this article

Cite this article

Gao, Q., Jin, P. & Cai, M. Research on sub-surface recrystallization of single crystal nickel-based superalloy in micro-milling. J Mech Sci Technol 33, 3467–3472 (2019). https://doi.org/10.1007/s12206-019-0641-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0641-2