Abstract

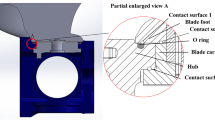

Rubber seals are used in the assemblies of mechanical parts in automobiles and aircrafts to prevent lubricant leakage and inclusion of foreign object. Because of the recent increase in the warranty periods of mechanical parts for automobiles, there is a need for longer service lives than those of existing products, and there is an even greater need for performance-related reliability during usage. This study analyzes the deformation behavior of rubber seals, including an overmold, used in the assemblies of mechanical parts. To improve the reliability of the analysis for rubber seal, three types of static experiments on rubber were conducted to obtain rubber properties. The experimental results were used to perform a hyper-elastic analysis considering rubber seal contact. The deformation analysis for rubber seal was performed to predict the performance after the assembling process. Moreover, a Monte Carlo simulation considering the probabilistic distribution of the mechanical properties of the rubber was performed to identify the effect of uncertainties in the rubber properties on deformation behavior of rubber seal. The pre- and post-deformation distributions of the rubber seal assembly were derived from the results of the Monte Carlo simulation, and they were used to evaluate the stability of the mechanical parts during the assembling process.

Similar content being viewed by others

References

I. K. Jun, W. J. Shim, I. H. Choi and C. K. Kim, Experimental study on the contact force of rubber seals for a ball bearing, Journal of KSLE, 9(1) (1993) 32–37.

S. H. Yoon, S. M. Jeon and J. H. Kim, Analysis of joints using metal seals in liquid rocket engine turbopump, Journal of the Korean Society of Propulsion Engineers, 17(6) (2013) 105–112.

S. P. Lee, K. S. Kim and B. K. Koh, Linear and nonlinear structural analysis for the assembled structures of pressure rice cooker, Journal of the Korea Academic-Industrial cooperation Society, 10(3) (2009) 493–499.

S. Lee and M. Park, Performance prediction on automotive wheel bearing seals, SAE International Journal of Passenger Cars — Mechanical Systems, 10(3) (2017) 805–810.

S. Lee, Drag torque prediction of automotive wheel bearing seals, Transactions of KSAE, 25(5) (2017) 563–572.

M. Hansen, Overmolding: A multifaceted medical device technology, Medical Device & Diagnostic Industry Magazine: MDDI Article, Medical Device & Diagnostic Industry (2006).

O. D. Anwana, H. Cai and H. T. Chang, Analysis of Brake Caliper Seal-groove Design, SAE Technical Paper (2002) 2002-01-0927.

E. Dragoni and A. Strozzi, Analysis of an unpressurized, laterally restrained, elastomeric O-ring seal, Journal of Tribology, 110(2) (1988) 193–200.

S. Lee, Reliability-based design optimization for composite wind turbine blades considering material uncertainty, New & Renewable Energy, 13(3) (2017) 41–50.

R. S. Rivlin, Large elastic deformations of isotropic IV, further developments of the general theory, Phill. Trans., 241 (1948) 379–397.

R. W. Ogden, Large deformation isotropic elasticity on the correlation of theory and experiments for incompressible rubber-like solid, Proc. R. Soc. Lond., 326 (1972) 565–584.

SAS IP, Inc., Engineering data user’s guide, ANSYS Workbench Documentation, ANSYS Release 18.1 (2016).

K. Miller, Testing Elastomers for Hyperelastic Material Models in Finite Element Analysis, Axel Products, Inc., Ann Arbor MI (2016).

ASTM International, ASTM D 412: Standard test methods for vulcanized rubber and thermoplastic elastomers — Tension, ASTM Internationa West Conshohocken, PA (2016).

Dassault Systeme Simulia, Component Guide, Isight User Assistance 2018, Isight Release (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jun-Sik Kim

Seung Pyo Lee received his B.S., M.S., and Ph.D. degrees in mechanical engineering from Hanyang University. Dr. Lee is currently a Director for Iljin Global and his research interests are in the area of FE analysis.

Ki Weon Kang is a Professor in School of Mechanical Convergence System Engineering at Kunsan National University. He earned his Ph.D. degree in 2001 from Hanyang University. His research interests lie in structural analysis and design for composite structure.

Rights and permissions

About this article

Cite this article

Lee, S.P., Kang, K.W. Deformation analysis of rubber seal assembly considering uncertainties in mechanical properties. J Mech Sci Technol 33, 3345–3353 (2019). https://doi.org/10.1007/s12206-019-0629-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0629-y