Abstract

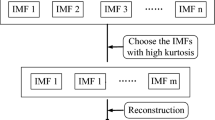

Previous research has shown that minimum entropy deconvolution (MED) is an effective technique for detecting impulse-like signals, such as the bearing fault and gear fault signals. However, some problems still exist in this technique. With the aim of overcoming these limitations, in this paper, an enhanced MED called multipoint optimal minimum entropy deconvolution adjusted (MOMEDA) is proposed. MOMEDA can succeed in detecting multiple impulses. Unfortunately, according to some simulations and real tests in this work, the results of applying this technique to the fault signals directly were grudgingly acceptable but not very satisfactory, especially under a harsh working condition. This means that MOMEDA is a little sensitive to intensive background noise and vibration interference. To overcome this drawback, a novel mode decomposition method, named time-varying filtering for empirical mode decomposition (TVFEMD), is applied to adaptively eliminate background noise and vibration interference prior to using MOMEDA. According to this proposed method, the weak bearing fault features can be identified clearly. The proposed approach is utilized in bearing fault detection of a spur gearbox and the results show its superiority and effectiveness.

Similar content being viewed by others

References

K. F. Al-Raheem et al., Rolling element bearing faults diagnosis based on autocorrelation of optimized: Wavelet de-noising technique, International J. of Advanced Manufacturing Technology, 40 (3–4) (2009) 393–402.

H. Qiu, J. Lee, J. Lin and G. Yu, Wavelet filter-based weak signature detection method and its application on rolling element bearing prognostics, J. of Sound and Vibration, 289 (4) (2006) 1066–1090.

A. Djebala, N. Ouelaa and N. Hamzaoui, Detection of rolling bearing defects using discrete wavelet analysis, Meccanica, 43 (3) (2008) 339–348.

H. Zhao et al., Study on a novel fault damage degree identification method using high-order differential mathematical morphology gradient spectrum entropy, Entropy, 20 (9) (2018) 1–18.

B. Eftekharnejad, M. R. Carrasco, B. Charnley and D. Mba, The application of spectral kurtosis on Acoustic Emission and vibrations from a defective bearing, Mechanical Systems and Signal Processing, 25 (1) (2011) 266–284.

J. Xiang, Y. Zhong and H. Gao, Rolling element bearing fault detection using PPCA and spectral kurtosis, Measurement, 75 (2015) 180–191.

S. Jin, J. S. Kim and S. K. Lee, Sensitive method for detecting tooth faults in gearboxes based on wavelet denoising and empirical mode decomposition, J. of Mechanical Science and Technology, 29 (8) (2015) 3165–3173.

W. Deng et al., A novel fault diagnosis method based on integrating empirical wavelet transform and fuzzy entropy for motor bearing, IEEE Access, 6 (2018) 35042–35056.

S. Jin and S.-K. Lee, Bearing fault detection utilizing group delay and the Hilbert-Huang transform, J. of Mechanical Science and Technology, 31 (3) (2017) 1089–1096.

Q. Xiong, Y. Xu, Y. Peng, W. Zhang, Y. Li and L. Tang, Low-speed rolling bearing fault diagnosis based on EMD denoising and parameter estimate with alpha stable distribution, J. of Mechanical Science and Technology, 31 (4) (2017) 1587–1601.

Y. Guo, J. Na, B. Li and R.-F. Fung, Envelope extraction based dimension reduction for independent component analysis in fault diagnosis of rolling element bearing, J. of Sound and Vibration, 333 (13) (2014) 2983–2994.

L. Han, C. W. Li, S. L. Guo and X. W. Su, Feature extraction method of bearing AE signal based on improved FAST-ICA and wavelet packet energy, Mechanical Systems and Signal Processing, 62 (2015) 91–99.

W. Deng et al., A novel intelligent diagnosis method using optimal LS-SVM with improved PSO algorithm, Soft Comput. (2017) 1–18.

T. Yang, H. Pen, Z. Wang and C. S. Chang, Feature knowledge based fault detection of induction motors through the analysis of stator current data, IEEE Transactions on Instrumentation and Measurement, 65 (3) (2016) 49–558.

W. Deng et al., A novel collaborative optimization algorithm in solving complex optimization problems, Soft Comput., 21 (15) (2017) 4387–4398.

Y. Lei, F. Jia, J. Lin, S. Xing and S. X. Ding, An intelligent fault diagnosis method using unsupervised feature learning towards mechanical big data, IEEE Transactions on Industrial Electronics, 63 (5) (2016) 3137–3147.

W. Deng et al., Study on an improved adaptive PSO algorithm for solving multi-objective gate assignment, Appl. Soft Comput. J., 59 (2017) 288–302.

T. Han, D. Jiang, Y. Sun, N. Wang and Y. Yang, Intelligent fault diagnosis method for rotating machinery via dictionary learning and sparse representation-based classification, Measurement, 99 (2018) 459–477.

Z. Wang, Z. Han, F. Gu, J. X. Gu and S. Ning, A novel procedure for diagnosing multiple faults in rotating machinery, ISA Transaction, 55 (2015) 208–218.

R. B. Randall, Vibration-based Condition Monitoring: Industrial, Aerospace and Automotive Applications, Wiley (2010).

R. A. Wiggins, Minimum entropy deconvolution, Geoexploration, 16 (1) (1978) 21–35.

H. Endo and R. B. Randall, Enhancement of autoregressive model based gear tooth fault detection technique by the use of minimum entropy deconvolution filter, Mechanical Systems and Signal Processing, 21 (2007) 906–919.

Q. Li, X. Ji and S. Y. Liang, Incipient fault feature extraction for rotating machinery based on improved AR-minimum entropy deconvolution combined with variational mode decomposition approach, Entropy, 19 (7) (2017) 317.

R. Jiang, J. Chen, G. Dong, T. Liu and W. Xiao, The weak fault diagnosis and condition monitoring of rolling element bearing using minimum entropy deconvolution and envelop spectrum, Proceedings of the Institution of Mechanical Engineers, Part C: J. of Mechanical Engineering Science, 227 (5) (2013) 1116–1129.

N. Sawalhi, R. B. Randall and H. Endo, The enhancement of fault detection and diagnosis in rolling element bearings using minimum entropy deconvolution combined with spectral kurtosis, Mechanical Systems and Signal Processing, 21 (6) (2007) 2616–2633.

G. L. McDonald and Q. Zhao, Multipoint optimal minimum entropy deconvolution and convolution fix: Application to vibration fault detection, Mechanical Systems and Signal Processing, 82 (2017) 461–477.

Z. Wang, J. Wang, Z. Zhao and R. Wang, A novel method for multi-fault feature extraction of a gearbox under strong background noise, Entropy, 20 (1) (2018) 10.

H. Li, Z. Li and W. Mo, A time varying filter approach for empirical mode decomposition, Signal Processing, 138 (2017) 146–158.

N. E. Huang, Z. Wu, S. R. Long, K. C. Arnold, X. Chen and K. Blank, On instantaneous frequency, Advances in Adaptive Data Analysis, 1 (2) (2009) 177–229.

N. Sawalhi and R. B. Randall, Simulating gear and bearing interactions in the presence of faults. Part I. The combined gear bearing dynamic model and the simulation of localised bearing faults, Mechanical Systems and Signal Processing, 22 (8) (2008) 1924–1951.

Y. Xu, Z. Cai and K. Ding, An enhanced bearing fault diagnosis method based on TVF-EMD and a high-order energy operator, Measurement Science and Technology, 29 (9) (2018) 095108.

Acknowledgments

The authors thank Prof. Bob Randall for providing the bearing fault data freely in his published book. This work is supported by the Fundamental Research Funds for the Central Universities, CHD (No. 300102258714 and 30010223801), the National Natural Science Foundation of China (No. 51705030), and the Special Funds for Education and Teaching reform for the Central Universities (No. 310625176501).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Kyoung-Su Park

Yuanbo Xu received a B.S. in Mechanical Engineering from Zhejiang SCI-TECH University, Hangzhou, China in 2009. He is currently a Ph.D. candidate at Chang’ an University. His primary research interest is machine fault diagnosis.

Zongyan Cai is a Professor of Mechanical Engineering at Chang’ an University. He received his Ph.D. from Northwestern Polytechnical University in China. His research interests include Intelligent robot technology, signal processing and Intelligent fault diagnosis.

Rights and permissions

About this article

Cite this article

Xu, Y., Cai, Z., Cai, X. et al. An enhanced multipoint optimal minimum entropy deconvolution approach for bearing fault detection of spur gearbox. J Mech Sci Technol 33, 2573–2586 (2019). https://doi.org/10.1007/s12206-019-0505-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0505-9