Abstract

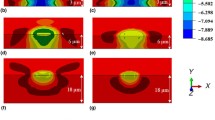

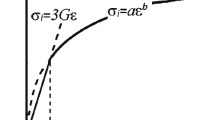

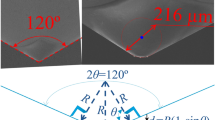

Nanoscratch testing is a highly reliable method used to extract a variety of film properties. It is proven that many of the experimental factors can influence the obtained results, such as the probe tilt, the scratch depth, etc. On the other hand, the surface roughness of the samples is an important parameter in nanoscratch and other similar tests, including the nanoindentation test. Thus, the effect of surface roughness on both the nanoscratch experiments and finite element simulations has been investigated. By performing scratch tests on gold and copper films and carrying out the finite element (FE) simulations on the rough and smooth surfaces, the importance of surface morphology was studied. The results indicate that the FE models consisting of the films with rough surfaces can lead to more accurate results, compatible with the experimental data. It was also revealed that the impact of surface morphology on the extracted friction coefficient tends to lose its significance in higher scratch depths. However, comparing the experimental results and simulation data, at lower scratch depths due to the presence of van der Waals forces the FE simulations will not lead to precise results.

Similar content being viewed by others

References

Y. Sun, T. Bell and S. Zheng, Finite element analysis of the critical ratio of coating thickness to indentation depth for coating property measurements by nanoindentation, Thin Solid Films, 258 (1–2) (1995) 198–204.

European Standard EN ISO 14577-1, Metallic materials, Instrumented indentation test for hardness and materials parameters, Part 1: Test method (2015).

K. D. Bouzakis, N. Michailidis, S. Hadjiyiannis, G. Skordaris and G. Erkens, The effect of specimen roughness and indenter tip geometry on the determination accuracy of thin hard coatings stress-strain laws by nanoindentation, Materials Characterization, 49 (2002) 149–156.

S. R. Pergande, A. A. Polycarpou and T. F. Conry, Use of nano-indentation and nano-scratch techniques to investigation near surface material properties associated with scuffing of engineering surface, ACRC TR-193, University of Illinois (2002).

H. Xie, J. Mead, S. Wang and H. Huang, The effect of surface texture on the kinetic friction of a nanowire on a substrate, Scientific Reports, 7 (2017) 44907.

B. D. Beake, A. A. Ogwu and T. Wagner, Influence of experimental factors and film thickness on the measured critical load in the nanoscratch test, Materials Science and Engineering: A, 423 (1) (2006) 70–73.

S. Lafaye and M. Troyon, On the friction behaviour in nanoscratch testing, Wear, 261 (7–8) (2006) 905–913.

N. Tayebi, A. A. Polycarpou and T. F. Conry, Effects of substrate on determination of hardness of thin films by nanoscratch and nanoindentation techniques, J. of Materials Research, 19 (6) (2004) 1791–1802.

Y. D. Yan, T. Sun and S. Dong, Study on effects of tip geometry on AFM nanoscratching tests, Wear, 262 (3–4) (2007) 477–483.

Y. Geng, J. Zhang, Y. Yan, B. Yu, L. Geng and T. Sun, Experimental and theoretical investigation of crystallographic orientation dependence of nanoscratching of single crystalline copper, PLoS ONE, 10 (7) (2015) e0131886.

J. Fu, S. Kamali-Bernard, F. Bernard and M. Cornen, Comparison of mechanical properties of CSH and portlandite between nano-indentation experiments and a modelling approach using various simulation techniques, Composites Part B: Engineering, 151 (2018) 127–138.

M. Chamani, G. H. Farrahi and M. R. Movahhedy, Friction behavior of nanocrystalline nickel near the Hall-Petch breakdown, Tribology International, 107 (2017) 18–24.

C. Shi, H. Zhao, H. Huang, S. Wan, Z. Ma, C. Geng and L. Ren, Effects of probe tilt on nanoscratch results: An investigation by finite element analysis, Tribology International, 60 (2013) 64–69.

A. Chatterjee, A. A. Polycarpou, J. R. Abelson and P. Bellon, Nanoscratch study of hard HfB2 thin films using experimental and finite element techniques, Wear, 268 (5–6) (2010) 677–685.

S. Roy, E. Darque-Ceretti, E. Felder, F. Raynal and I. Bispo, Experimental analysis and finite element modelling of nano-scratch test applied on 40–120 nm SiCN thin films deposited on Cu/Si substrate, Thin Solid Films, 518 (2010) 3859–3865.

H. R. Chamani and M. R. Ayatollahi, The effect of Berkovich tip orientations on friction coefficient in nano-scratch testing of metals, Tribology International, 103 (2016) 25–36.

H. R. Chamani and M. R. Ayatollahi, Prediction of friction coefficients in nanoscratch testing of metals based on material flow lines, Theoretical and Applied Fracture Mechanics, 94 (2018) 186–196.

R. Hu, C. Prakash, V. Tomar, M. Harr, I. E. Gunduz and C. Oskay, Experimentally-validated mesoscale modeling of the coupled mechanical-thermal response of AP-HTPB energetic material under dynamic loading, International J. of Fracture, 203 (1) (2017) 277–298.

A. Wagih and A. Fathy, Experimental investigation and FE simulation of nano-indentation on Al-Al2O3 nanocomposites, Advanced Powder Technology, 27 (2) (2016) 403–410.

C. H. Sacre, F. Lani, P. Guaino, L. Libralesso, A. Favache and T. Pardoen, Effect of polymer interlayer on scratch resistance of hard film, Experiments and finite element modeling, Wear, 378 (2017) 136–144.

W. C. Oliver and G. M. Pharr, An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments, J. of Materials Research, 7 (1992) 1564–1583.

S. H. Hong, K. S. Kim, Y. M. Kim, J. H. Hahn, C. S. Lee and J. H. Park, Characterization of elastic moduli of Cu thin films using nanoindentation technique, Composites Science and Technology, 65 (9) (2005) 1401–1408.

E. T. Lilleodden, J. A. Zimmerman, S. M. Foiles and W. D. Nix, Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation, J. of the Mechanics and Physics of Solids, 51 (5) (2003) 901–920.

D. Tabor, The Hardness of Metals, 1st Ed., Oxford Clarendon Press (1951).

A. C. Fischer-Cripps, Nanoindentation, 2st Edition, Mechanical Engineering Series, Springer (2011).

A. F. Jankowski and H. T. Ahmed, The nanoscratch hardness of a gold-nickel nanocrystalline nanolaminate at high strain rate, Materials Letters, 77 (2012) 103–106.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dong-Weon Lee

M. Nazemian received his M.Sc. in Mechanical Engineering at Sharif University of technology in 2014. His major research interests are numerical methods, fatigue and fracture mechanics, nanomechanics and materials science.

M. Chamani received his Ph.D. in Mechanical Engineering at Sharif University of technology in 2016. His core research interests include nanotechnology, molecular dynamics and wind turbine. He is working as a researcher at Niroo Research Institute.

Rights and permissions

About this article

Cite this article

Nazemian, M., Chamani, M. Experimental investigation and finite element simulation of the effect of surface roughness on nanoscratch testing. J Mech Sci Technol 33, 2331–2338 (2019). https://doi.org/10.1007/s12206-019-0432-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0432-9