Abstract

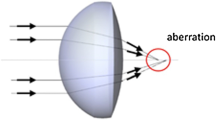

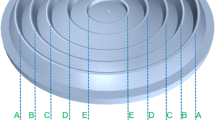

The Blu-ray objective lens is one of the electronic parts that has an important role in data storage in such a way that its production requires a high level of accuracy. One way to produce the Blu-ray objective lens is by means of a micro-injection molding technique. We investigated the effect of insert part in a multi-shot injection molding on the shrinkage after the process of injection. An aspherical shape is made for the insert part of the Blu-ray objective lens, then compared with single-shot injection molding. Zemax software was used to design the Blu-ray objective lens, while Moldex3D software was applied to analyze the flow of material into the mold during the injection process. The Taguchi method was used to determine the best parameters to obtain the minimum shrinkage values of the injection processes of both multi-shot injection and single-shot injection molding techniques. Based on the observations, it is clearly evident that the multi-shot injection molding process has a lower displacement value compared to the single-shot injection molding, namely, 0.0161 mm compared to 0.0550 mm and also the multi-shot injection can save the cooling time 5 seconds faster than single-shot injection molding. So, this can favorably improve the production of the injection process for the material in the form of the micro part.

Similar content being viewed by others

References

D. Chen, D. Chen and B. Wang, The advantages of Blu-ray disc, Proc. SPIE, 5966 (2005) 1–5.

M. Nobuyoshi, K. Tohru, T. Kyu, H. Junji, O. Yuichiro and M. Nobuo, Plastic objective lens for Blu LD optical pick up, Konica Minolta Technology Report, 2 (2005) 153–156.

W. Guo, L. Hua, H. Mao and Z. Meng, Prediction of warpage in plastic injection molding based on design of experiments, J. of Mechanical Science and Technology, 26 (4) (2012) 1133–1139.

A. Mamat, T. F. Trochu and B. Sanschagrin, Analysis of shrinkage by dual Kriging for filled and unfilled polypropylene moulded part, Polymer Engineering and Science, 35 (19) (1995) 1511–1520.

K. M. Tsai, C. Y. Hsieh and W. C. Lo, A study of the effect of process parameter for injection molding on the surface quality of optical lenses, Material Processing Technology, 209 (2009) 3469–3477.

S. Kitayama and S. Natsume, Multi-objective optimization of volume shrinkage and clamping force for plastic injection molding via approximate sequential optimization, Simulation Modelling Practice and Theory, 48 (2014) 35–44.

M. W. Wang, Micro-ceramic injection molding of a multi shot micro patterned micro part, International J. of Advanced Manufacturing Technology, 51 (2010) 145–153.

R. J. Bensingh, S. R. Boopathy and C. Jebaraj, Minimization of variation in volumetric shrinkage and deflection on injection molding of Bi-aspheric lens using numerical simulation, J. of Mechanical Science and Technology, 30 (11) (2016) 5143–5152.

C. H. Wu and W. S. Chen, Injection molding and injection compression molding of the three-beam grating of DVD pickup lens, Sensors and Actuators A: Physical, 125 (2005) 367–375.

G. W. M. Peter, P. J. L. van der Velden and H. E. H. Meijer, Multilayer injection molding Part2: Particle tracking in reactive molding. International Polymer Process, 9 (1994) 258–265.

C. Maier, J. Giessauf and G. Steinbichler, Efficient production of thick-walled parts, Kunststoffe International, 9 (2013) 15–19, www.kunststoffeinternational.com, Document Number. PE111447.

C. Hopmann, A. Neuss, M. Weber and P. Walach, Multi shot injection molding of thick-walled optical plastics parts, Proceedings of PPS-29, AIP Conf. Proc, 1593 (2014) 146–149.

G. I. Kweon, Aspherical lens design by using a numerical analysis, J. of the Korean Physical Society, 51 (1) (2007) 93–103.

A. W. Greynolds, Superconic and subconic surface descriptions in optical design, Proc. SPIE., 4832 (2002) 1–9.

H. Oktem, T. Erzurumlu and I. Uzman, Application of Taguchi optimization technique in determining plastic injection molding process parameters for a thin-shell part, Materials & Design, 28 (4) (2017) 1271–1278.

K. Lee and J. C. Lin, Optimization of injection molding parameters for LED lampshade, Transactions of the Canadian Society for Mechanical Engineering, 37 (3) (2013) 313–323.

T. Erzurumlu and B. Ozcelik, Minimization of warpage and sink index in injection-molded thermoplastic parts using Taguchi optimization method, Materials & Design, 27 (10) (2006) 853–861.

G. H. R. Pundir, V. C. Chary and M. G. Dastidar, Application of Taguchi method for optimizing the process parameters for the removal of copper and nickel by growing aspergillus sp, Water Resources and Industry (2016) 1–10.

J. C. Lin and K. S. Lee, Molding analysis of multi-cavity aspheric lens and mold designing, Advances in Materials and Processing Technologies, ISSN: 1662–8985, 83–86 (2009) 77–87.

H. E. Lai and P. J. Wang, Study of process parameters on optical qualities for injection-molded plastic lenses, Applied Optics, 47 (12) (2008) 2017–2027.

S. Wang, J. Ying, Z. Chen and K. Cai, Grey fuzzy PI control for packing pressure during injection molding process, J. of Mechanical Science and Technology, 25 (4) (2011) 1061–1068.

C. Chang, A. Chen, T. V. Lien and Y. T. Qiu, Study on injection molding of shell mold for aspheric contact lens Fabrication, Advances in Material & Processing Technologies Conference, Procedia Engineering, 184 (2017) 344–349.

G. Taguchi, S. Chowdhury and Y. Wu, Taguchi’s quality engineering handbook, Hoboken: Wiley (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Yongho Jeon

Min-Wen Wang is a Professor at the National Kaohsiung University of Science and Technology. His research interests include micro-molding, LIGAlike, and additive manufacturing technologies.

Fatahul Arifin is a Ph.D. candidate at the National Kaohsiung University of Science and Technology. His research interests include production engineering, plastic processing, micro injection molding, advance manufacturing technology and engineering material and technology.

Rights and permissions

About this article

Cite this article

Wang, MW., Chen, CH., Arifin, F. et al. Modeling and analysis of multi-shot injection molding of Blu-ray objective lens. J Mech Sci Technol 32, 4839–4849 (2018). https://doi.org/10.1007/s12206-018-0932-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0932-z