Abstract

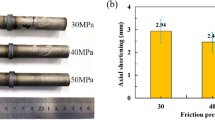

The aim of this investigation was to explore the effect of geometric tool parameters and tool probe offset on the properties of friction stir welded of 2 mm thick plates of Ti6Al4V to AA5052-H32 joints. In a probe offset distance of 0.5 mm, sound dissimilar joint with tensile strength higher than 94 % of the parent AA5052 alloy strength is produced. Increasing the probe offset distance result in more homogenous and higher quantity of titanium alloy particles in the weld nugget. Increasing welding heat input results in change of fracture zone from TMAZ of AA5052 side to weld interface. It was found that the tool with square frustum pin produces joints without defect and high strength compared to the cylindrical pin.

Similar content being viewed by others

References

B. Li, Z. Zhang, Y. Shen, W. Hu and L. Luo, Dissimilar friction stir welding of Ti6Al4V alloy and aluminum alloy employing a modified butt joint configuration: Influences of process variables on the weld interfaces and tensile properties, Materials and Design, 53 (2014) 838–848.

Y. Wei, J. Lib, J. Xiong, F. Huang, F. Zhang and S. H. Raza, Joining aluminum to titanium alloy by friction stir lap welding with cutting pin, Materials Characterization, 71 (2012) 1–5.

Z. Song, K. Nakata, A. Wu, J. Liao and L. Zhou, Influence of probe offset distance on interfacial microstructure and mechanical properties of friction stir butt welded joint of Ti6Al4V and A6061 dissimilar alloys, Materials and Design, 57 (2014) 269–278.

B. Li, Y. Shen, L. Luo and W. Hu, Effects of processing variables and heat treatments on Al/Ti-6Al-4V interface microstructure of bimetal clad-plate fabricated via a novel route employing friction stir lap welding, Journal of Alloys and Compounds, 658 (2016) 904–913.

M. Krutzlinger, R. Marstatt, S. Suenger, J. Luderschmid, M. Friedrich Zaeh and F. Haider, Formation of joining mechanisms in friction stir welded dissimilar Al-Ti lap joints, Advanced Materials Research, 966–967 (2014) 510–520.

B. K. Dhindaw and P. S. De, Friction stir welding of aluminum alloy 1100 and titanium-Al alloy, Proceedings of the ASME 2016 International Manufacturing Science and Engineering Conference, Blacksburg, Virginia, USA (2016).

Y. Chen, C. Liu and G. Liu, Study on the joining of titanium and aluminum dissimilar alloys by friction stir welding, The Open Materials Science Journal, 5 (2011) 256–261.

T. R. McNelley, S. Swaminathan and J. Q. Su, Recrystallization mechanisms during friction stir welding/processing of aluminum alloys, Scripta Materialia, 85 (2008) 349–354.

F. J. Humphreys and M. Hatherly, Recrystallization and related annealing phenomena, Elsevier, Kidlington, Oxford OX5 1GB, UK (2004).

Z. Zhang and H. W. Zhang, Solid mechanics-based Eulerian model of friction stir welding, The International Journal of Advanced Manufacturing Technology, 72 (2014) 1647–1653.

J. Marzbanrad, M. Akbari, P. Asadi and S. Safaee, Characterization of the influence of tool pin profile on microstructural and mechanical properties of friction stir welding, Metallurgical and Materials Transactions B, 45 (2014) 1887–1894.

N. Kumar, W. Yuan and R. S. Mishra, Friction stir welding of dissimilar alloys and materials, Elsevier (2015).

M. J. Peel, A. Steuwer and P. J. Withers, Dissimilar friction stir welds in AA5083-AA6082. Part II: Process parameter effects on microstructure, Metallurgical and Materials Transactions A, 37 (2006) 2195–2206.

M. Peel, A. Steuwer, M. Preuss and P. J. Withers, Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds, Acta materialia, 51 (2003) 4791–4801.

M. Jafari, M. Abbasi, D. Poursina, A. Gheysarian and B. Bagheri, Microstructures and mechanical properties of friction stir welded dissimilar steel-copper joints, Journal of Mechanical Science and Technology, 31 (2017) 1135–1142.

E.-Y. Ahn, H. Das, S.-T. Hong, K.-S. Han, M. Miles, K.-J. Lee, J.-W. Park and H. N. Han, Process responses and resultant joint properties of friction stir welding of dissimilar 5083 and 6061aluminum alloys, Journal of Mechanical Science and Technology, 31 (2017) 3955–3960.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

Hossein Rostami is a M.S. student in Materials engineering at Babol Noshirvani University of Technology, Iran.

Salman Nourouzi is Associate Professor of Materials and Industrial engineering department at the Babol Noshirvani University of Technology, Iran. He received his Ph.D. in Surface Engineering from Limoges University, France.

Hamed Jamshidi Aval is Assistant Professor of Materials and Industrial engineering department at the Babol Noshirvani University of Technology, Iran. He received his Ph.D. in Material science and engineering from Sharif University of Technology, Iran.

Rights and permissions

About this article

Cite this article

Rostami, H., Nourouzi, S. & Jamshidi Aval, H. Analysis of welding parameters effects on microstructural and mechanical properties of Ti6Al4V and AA5052 dissimilar joint. J Mech Sci Technol 32, 3371–3377 (2018). https://doi.org/10.1007/s12206-018-0640-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0640-8