Abstract

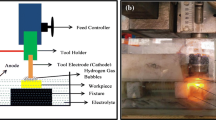

An electrically conductive SiC-Ti2CN composite was fabricated from β-SiC and TiN powders with 2 vol% equimolar Y2O3-Sc2O3 additives by conventional hot-pressing. The composite (electrical resistivity of nearly 10-4 Ω·cm) was wire electro discharge machined into a specimen having a thickness of 500 μm. Entrance clearance, machining time, number of shorts, material removal rate (MRR), counts, and the effects of the capacitance and voltage of conductive SiC-Ti2CN composite during micro electrical discharge drilling were measured and compared to those of SUS304. As the unit discharge energy increased, entrance clearance, machining time, and number of shorts decreased. A decrement in the number of shorts was the main reason for decrements in entrance clearance and machining time. MRR was proportional to unit discharge energy. The study to determine the location of shorts during electro discharge drilling was also conducted. It was founded that the short circuit occurred mainly at the beginning (0–1000 cts) because of low electrical density, and right before the exit (3000–5000 cts) owing to the difficulty of removing debris. Both the capacitance and voltage tended to be inversely proportional to the number of shorts.

Similar content being viewed by others

References

C. F. Hu, Y. C. Zhou and Y. W. Bao, Material removal and surface damage in EDM of Ti3SiC2 ceramic, Ceram. Int., 34 (2008) 537–541.

Y.-W. Kim, K. J. Kim, H. C. Kim, N.-H. Cho and K.-Y. Lim, Electrodischarge-machinable silicon carbide ceramics sintered with yttrium nitrate, J. Am. Ceram. Soc., 94 (2011) 991–993.

H.-K. Yoo, J.-H. Ko, K.-Y. Lim, W. T. Kwon and Y.-W. Kim, Micro-electrical discharge machining characteristics of newly developed conductive SiC ceramic, Ceram. Int., 41 (2015) 3490–3496.

A. Torres, C. J. Luis and I. Puertas, EDM machinability and surface roughness analysis of TiB2 using copper electrodes, J. Alloys, Comp., 690 (2017) 337–347.

B. Lauwers, K. Brans, W. Liu and K. Vanmeensel, Influence of the type and grain size of the electrode-conductive phase on the Wire-EDM performance of ZrO2 ceramic composites, CIRP Ann. Manuf. Technol., 57 (2008) 191–194.

B. Lauwers, J. P. Kruth, W. Liu, W. Eeraerts, B. Schacht and P. Bleys, Investigation of material removal mechanisms in EDM of composite ceramic materials, J. Mater. Process Tech., 149 (2004) 347–352.

E. Ferraris, D. Reynaerts and B. Lauwers, Micro-EDMprocess investigation and comparison performance of Al2O3 and ZrO2 based ceramic composites, CIRP Ann. Manuf. Technol., 60 (2011) 235–238.

P. Ninz, R. Landfired, F. Kern and R. Gadow, Electrical discharge machining of metal doped Y-TZP/TiC nanocomposites, J. Eur. Ceram. Soc., 35 (2015) 4031–4037.

Selvarajan L., M. Manohar, A. Udhaya kumar and P. Dhinakaran, Modelling and experimental investigation of process parameters in EDM of Si3N4-TiN composites using GRA-RSM, J. Mech. Sci. Tech., 31 (1) (2017) 111–122.

C. Diver, J. Atkinson, H. J. Helml and L. Li, Micro-EDM drilling of tapered holes for industrial applications, J. Mater. Proc. Technol., 149 (2004) 296–303.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor In-Ha Sung

Joon Yeong Gwon received his B.S. and M.S. in Mechanical Information Engineering from University of Seoul. He is currently an Associate Rotary Compressor Development team in LG Electronics. He is involved in developing 9 frame rotary compressor for air conditioner.

Won Tae Kwon received his B.S., M.S. degrees from Seoul National University, and Ph.D. degree from Northwestern University in 1982, 1984 and 1992, respectively. Prof. Kwon is currently a Professor of the Department of Mechanical and Information Engineering of University of Seoul, Korea. His research fields include micro machining and machining process optimization.

Young-Wook Kim received his B.S. from Yonsei University in 1981, and M.S. and Ph.D. degrees in Materials Science and Engineering from the Korea Advanced Institute of Science and Technology (KAIST), Korea, in 1983 and 1990, respectively. He is currently a Professor of Materials Science and Engineering at University of Seoul. Prof. Kim is a fellow of the American Ceramic Society and academician in World Academy of Ceramics. His research interests include the microstructural control of nonoxide ceramics, the mechanical, tribological, electrical and thermal properties of SiC ceramics, and the processing of SiC membranes.

Rights and permissions

About this article

Cite this article

Gwon, J.Y., Jang, S.H., Kwon, W.T. et al. Micro electrical discharge drilling characteristics of conductive SiC–Ti2CN composite. J Mech Sci Technol 32, 3351–3358 (2018). https://doi.org/10.1007/s12206-018-0638-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0638-2