Abstract

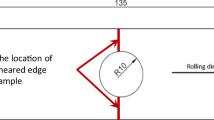

As the traditional uniaxial test requires substantial amount of cost and material usage for specimen, it is hardly applied to the direct diagnosis of structural integrity of in-service facilities. Small punch (SP) test has been, alternatively, introduced to procure material properties because SP test just needs a slice of material (10 × 10 × 0.5 mm) which can be easily obtained from real components without loss of integrity. In this study, for HR3C steel, SP tests were carried out and its three-dimensional finite element (FE) model was also developed to cross-validate the test results. Scanning electron microscope images for SP specimens were taken and compared with crack propagation simulation results generated by the extended finite element method. Furthermore, the minimum thickness change of specimen during the test was measured by several interruption tests. Configuration of SP test specimen was intensively observed with respect to punch displacement by both experiment and FE analysis, respectively.

Similar content being viewed by others

References

S. Hwang, Current status and vision on Shin Boryeong 1,000 MW USC plant construction, Journal of Electrical World Monthly Magazine, 445 (1) (2014) 45–51 (Korean).

C. Chi, H. Yu and X. Xie, Advanced austenitic heat-resistant steels for ultra-super-critical (USC) fossil power plants, INTECH Open Access Publisher (2011).

A. Iseda et al., Long term creep properties and microstructure of SUPER304H, TP347HFG and HR3C for A-USC boilers, Energy Materials, 2 (2007) 199–206.

M. P. Manahan, A new postirradiation mechanical behavior test—the miniaturized disk bend test, Nuclear Technology, 63 (1983) 295–315.

X. Mao, M. Saito and H. Takahashi, Small punch test to predict ductile fracture toughness JIC and brittle fracture toughness KIC, Scripta Metallurgica et Materialia, 25 (11) (1991) 2481–2485.

J. R. Foulds et al., Fracture toughness by small punch testing, Journal of Testing and Evaluation, 23 (1) (1995) 3–10.

K. Milicka and F. Dobeš, Small punch testing of P91 steel, International Journal of Pressure Vessels and Piping, 83 (9) (2006) 625–634.

T. E. García et al., Estimation of the mechanical properties of metallic materials by means of the small punch test, Journal of alloys and compounds, 582 (2014) 708–717.

J. D. Parker and J. D. James, Disc-bend creep deformation behaviour of 0.5 Cr 0.5 Mo 0.25 V low alloy steel, Creep and Fracture of Engineering Materials and Structures (1993) 651–660.

N. Moes, J. Dolbow and T. Belytschko, A finite element method for crack growth without remeshing, International Journal for Numerical Methods in Engineering, 46 (1999) 131–150.

V. Tvergaard and A. Needleman, Analysis of the cup-cone fracture in a round tensile bar, Acta metallurgica, 32 (1) (1984) 157–169.

V. Tvergaard, Influence of void nucleation on ductile shear fracture at a free surface, Journal of the Mechanics and Physics of Solids, 30 (6) (1982) 399–425.

A. L. Gurson, Continuum theory of ductile rupture by void nucleation and growth: Part I—Yield criteria and flow rules for porous ductile media, Journal of Engineering Materials and Technology, 99 (1) (1977) 2–15.

Y. S. Chang et al., Derivation of ductile fracture resistance by use of small punch specimens, Engineering Fracture Mechanics, 75 (11) (2008) 3413–3427.

E. M. Parieda, T. E. Garcia and C. Rodriguez, Fracture toughness characterization through notched small punch test specimens, Material Science and Engineering A, 657 (2016) 422–430.

ASTM E8: Standard test methods for tension testing of metallic materials, Annual book of ASTM standards, ASTM (2001).

D. T. Gawne and U. Ma, Friction and wear of Chromium and Nickel coating, Wear, 129 (1989) 123–142.

Y. W. Ma, S. Shim and K. B. Yoon, Assessment of power law creep constants of Gr91 steel using small punch creep tests, Fatigue & Fracture of Engineering Materials & Structures, 32 (12) (2009) 951–960.

X. Mao, T. Shoji and H. Takahashi, Characterization of fracture behavior in small punch test by combined recrystallization-etch method and rigid plastic analysis, Journal of Testing and Evaluation, 15 (1987) 30–37.

B. C. Punmia et al., Mechanics of materials, firewall media, New Delhi, India (2002).

W. Cai, Fracture simulation of structural steel at elevated temperature using XFEM technique, IOP Conference Series: Materials Science and Engineering, 264 (1) IOP Publishing (2017).

T. E. García et al., Estimation of the mechanical properties of metallic materials by means of the small punch test, Journal of Alloys and Compounds, 582 (2014) 708–717.

C. Rodríguez et al., Mechanical properties characterization of heat-affected zone using the small punch test, Welding Journal, 88 (9) (2009) 188–192.

X. Mao and H. Takahashi, Development of a furtherminiaturized specimen of 3 mm diameter for tem disk (ø 3 mm) small punch tests, Journal of Nuclear Materials, 150 (1) (1987) 42–52.

V. Vorlicek, L. F. Exworthy and P. E. J. Flewitt, Evaluation of a miniaturized disc test for establishing the mechanical properties of low-alloy ferritic steels, Journal of Materials Science, 30 (11) (1995) 2936–2943.

Y. Ruan, P. Spätig and M. Victoria, Assessment of mechanical properties of the martensitic steel EUROFER97 by means of punch tests, Journal of Nuclear Materials, 307 (2002) 236–239.

E. N. Campitelli et al., Assessment of the constitutive properties from small ball punch test: Experiment and modeling, Journal of Nuclear Materials, 335 (3) (2004) 366–378.

E. Martínez-Pañeda et al., Damage modeling in small punch test specimens, Theoretical and Applied Fracture Mechanics, 86 (2016) 51–60.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Nam-Su Huh

Moon Ki Kim received B.S. and M.S. degrees in Mechanical Engineering Seoul National University in 1997 and 1999, respectively, and Ph.D. degrees from Johns Hopkins University in 2004. He had been an Assistant Professor in the Department of Mechanical and Industrial Engineering at University of Massachusetts, Amherst from 2004 to 2008. In 2008, he joined Sungkyunkwan University, where he is currently a Professor in School of Mechanical Engineering. His research interests are focused on computational structural biology based on robot kinematics, bioinstrumentations, and multiscale modeling and simulation.

Taeksang Lee received B.S. and M.S. degrees in Mechanical Engineering from Sungkyunkwan University in 2014 and 2016, respectively. He is currently a Ph.D. student in School of Mechanical Engineering at Purdue University. His research interest is focused on biological membrane based on computational mechanics.

Hoomin Lee received B.S. degree in Mechanical Engineering from Sungkyunkwan University in 2012. He is currently taking a unified M.S. and Ph.D. course in School of Mechanical Engineering in Sungkyunkwan University. His research interests are Multi-physics simulations on continuum domain.

Rights and permissions

About this article

Cite this article

Lee, T., Lee, H., Kang, S.J. et al. Small punch test and simulation of HR3C steel. J Mech Sci Technol 32, 3115–3121 (2018). https://doi.org/10.1007/s12206-018-0614-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0614-x