Abstract

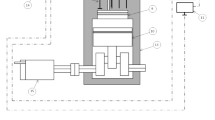

The future internal-combustion (IC) engines should have minimum emissions level under lowest feasible fuel consumption. This aim can be achievable with a homogeneous combustion process in diesel engines. We used a porous medium (PM) to homogenize the combustion process. This research studies simulation of a direct-injection diesel engine, equipped with a chemically inert hemispherical PM. Methane is injected into a hot PM, assuming mounted up the cylinder in head. Combustion with lean mixture occurs inside PM. A numerical model of PM engine was carried out using a modified version of the KIVA-3V code. PM results were evaluated with experimental data of unsteady combustion-wave of methane in a porous tube. The results show the mass fraction of methane, CO, NO and temperature in solid and gas phases of the PM and in-cylinder fluid. Also presented are the effects of injection timing and compression ratio on combustion.

Similar content being viewed by others

References

R. H. Stanglmaier and C. E. Roberts, Homogeneous charge compression ignition: Benefits, compromises and future engine applications, SAE Paper 1999-01-3682 (1999).

M. Weclas, Potential of porous medium combustion technology as applied to internal combustion engine, MECA/AECC Meeting, Nurnberg, Germany (2001).

M. Weclas, New strategies for homogeneous combustion in I.C. engines based on the porous medium (PM)-technology, ILASS Europe (2001).

M. Weclas, Strategy for intelligent internal combustion engine with homogeneous combustion in cylinder, Georg Simon Ohm University of Applied Sciences in Nuremberg, 26 (2004) 1–14.

D. Trim and F. Durst, Combustion in porous medium -advances and application, J. Combust Sci. and Tech., 121 (1996) 153–168.

M. M. Kamal and A. A. Mohammad, Combustion in porous media, Proc. IMeche, 220 (2006) 478–508.

R. C. M. Filho and A. P. Pimenta, A two-dimensional numerical simulation of combustion and heat transfer in radiant porous burners, Combust Sci. and Tech., 138 (2011) 370–389.

F. Durst and M. Weclas, A new type of internal combustion engine based on the porous medium technology, Proc. Inst. Mech. Eng., 215 (2001) 63–81.

F. Durst and M. Weclas, A new concept of I.C engine with homogeneous combustion in a porous medium, The Fifth International Symposium on Diagnostic and Modeling of Combustion in Internal Combustion Engines, Nagoya, Japan (2001).

C. W. Park and M. Kaviany, Evaporating combustion affected by in cylinder reciprocating porous regenerator, ASME J. Heat Transfer, 124 (2002) 184–194.

M. Polasek and J. Macek, Homogenization of combustion in cylinder of CI engine using porous medium, SAE Paper, 2003-01-1085 (2003).

L. D. Chein, J. O. Chae and Y. H. Kwak, Improving surface characteristic of porous media reactor in diesel engine by plasma technology, FISITA 2006 World Automotive Congress, Yokohama, Japan (2006).

M. Weclas and R. Faltermeier, Diesel jet impingement on small cylindrical obstacles for mixture homogenization by late injection strategy, Int. J. Engine Research, 8 (2007) 399–413.

Z. Zhigou and X. Mahozhao, Numerical study on the compression ignition of a porous medium engine, Springer, 51 (2008) 277–287.

Z. Zhigou and X. Mahozhao, Numerical simulation about interaction between pressure swirl spray and hot porous medium, Energy Conversion & Management, 49 (2008) 1047–1055.

L. Hongsheng, X. Maozaho, C. Shi and L. Hong, Simulation of porous media engine using a two-zone combustion model, SAE Paper, 2008-01-1516 (2008).

L. Hongsheng, X. Maozaho and W. Dan, Thermodynamic analysis of regenerative cycle in porous medium engine, J. Energy Conversion and Management, 50 (2009) 297–303.

Z. Zhao, C. Wang and X. Maozhao, Numerical study on the realization of compression ignition in a type of porous medium engine fueled with isooctane, J. Fuel, 88 (2009) 2291–2296.

M. Weclas and J. Cypris, Role of jet core in splashing patterns of diesel jet impingement on the solid wall, Int. J. Engine Research, 11 (2010) 29–46.

A. Mohammadi, A. Jazayeri and M. Ziabasharhagh, Numerical simulation of porous medium in internal combustion engine, Proceedings of ASME-JSME-KSME Joint Fluids Engineering Conference, Hamamatsu, Shizuoka, Japan (2011).

A. Mohammadi, A. Jazayeri and M. Ziabasharhagh, Numerical simulation of direct injection engine with porous medium, Proceedings of the ASME Internal Combustion Engine Division, Spring Technical Conference, Torino, Italy (2012).

A. Mohammadi, Numerical simulation of spark ignition engines, Numerical simulations–examples and applications in computational fluid dynamics, Lutz Angermann (Ed.), ISBN: 978-953-307-153-4, InTech, Croatia (2010).

A. A. Amsden, P. J. O’Rourke and Butler, KIVA-II: A computer program for chemically reactive flows with sprays, Los Alamos National Laboratory Report LA-11560-MS, Los Alamos (1989).

A. A. Amsden, KIVA-3V: A Block-Structured KIVA program for engines with vertical or canted valves, Los Alamos National Laboratory Report LA-13313-MS, Los Alamos (1997).

J. Prieur du Plessis and S. Woudberg, Pore-scale derivation of the Ergun equation to enhance its adaptability and generalization, J. Chemical Engineering Science, 63 (2008) 2576–2586.

N. Wakao and S. Kaguei, Heat and mass transfer in packed beds, Gordon and Breach Science Publications, New York, USA (1982).

B. F. Magnussen and B. H. Hjertager, Mathematical modeling of turbulent combustion with special emphasis on soot formation and combustion, The Sixteenth Int. Symposium on Combustion, The Combustion Institute, Pittsburgh (1977).

M. Adžić, V. Fotev, V. Jovičić, A. Milivojević, G. Milekić, V. Adžić and M. Bogner, Potentials for usage of significantly reduced chemical mechanisms in numerical modeling of combustion processes, FME Transactions, 36 (2008) 1–7.

M. F. Modest, Radiative heat transfer, Academic Press, California, USA (2003).

T. J. Hendricks and J. R. Howell, Absorption/scattering coefficients and scattering phase functions in reticulated porous ceramics, J. Heat Trans., 118 (1) (1996).

Y. Ra, S. C. Kong, R. D. Reitz, C. J. Rutland and Z. Han, Multi-dimensional modelling of transient gas jet injection using coarse computational grids, SAE paper 2005-01-0208 (2005).

A. Ferrenberg and B. E. Williams, Progress in the development of regenerated diesel engine, SAE 961677 (1996).

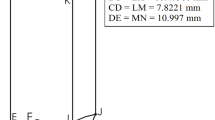

S. Zhdanok, Super adiabatic combustion of methane air mixture under filtration in a packed bed, J. Combustion and Flame, 100 (1995) 221–231.

M. Ziabasharhagh and A. Mohammadi, Numerical simulation of combustion in porous media, numerical simulations -from theory to industry, Mikhaylo Andriychuk (Ed.), ISBN: 978-953-51-0749-14, InTech, Croatia (2012).

A. Mohammadi, Control emission of combustion in compression ignition engine with using porous medium, Ph.D. Thesis, KNToosi University of Technology, September (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jeong Park

Arash Mohammadi recived B.S., MS.C., and Ph.D. in Mechanical Engineering from Kerman University, Shiraz University and KNT University of Technology, respectively. In 2015, he joined Shahid Rajaee Univerity as Assistant Professor. His research interests and activity include CFD, IC engines, Combustion in porous media, two phase flow simulation.

Mostafa Varmazyar recived his B.S, M.S. and Ph.D. in Mechanical Engineering from Iranian university of Science and Technology, KNT University of Technology, respectively. In 2014, he joined Shahid Rajaee University as assistant professor. His research interests and activity include lattice Boltzmann method and supercritical fluid flow simulation.

Reza Hamzeloo received his B.S. in Manufacturing from University of Tabriz, and M.S. and Ph.D. in Mechanical Engineering from Amirkabir University of Technology in 2007 and 2012, respectively. He is currently an Assistant Professor at Shahid Rajaee University. His main activity and interest focus on structural health monitoring, mechatronics, manufacturing procedures and analysis with finite element method.

Rights and permissions

About this article

Cite this article

Mohammadi, A., Varmazyar, M. & Hamzeloo, R. Simulation of combustion in a porous-medium diesel engine. J Mech Sci Technol 32, 2327–2337 (2018). https://doi.org/10.1007/s12206-018-0444-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0444-x