Abstract

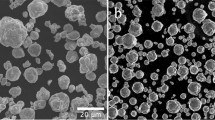

Aluminum anodizing is a process in which metal is oxidized with an electrochemical method to make a metallic oxide. Because it can be used to manufacture an Anodic aluminum oxide (AAO) with dozens to hundreds of nanoscale pores that are vertically and uniformly arranged, it is widely applied in a variety of fields. In particular, most of the pre-treatment methods in the anodic oxidation processes using a high-purity aluminum adopt surface treatment through electrolyte polishing. In this study, complex polishing was performed using an abrasive film and Magnetorheological (MR) fluid for a commercial aluminum alloy to produce a uniform porous oxidized aluminum. The surface roughness and surface integrity were analyzed after each process to investigate the production behavior of AAO in relation to the pre-treatment of the surface. In addition, a study was conducted on the nano-pore production by the anodizing process in accordance with the pre-treatment polishing, in terms of the work-hardening and residual stress. Thus, in the anodic oxidation process, it was possible to generate uniform nano-pores when surface integrity including surface roughness and residual stress distribution of the aluminum alloys are excellent. Test results showed that the polishing process using the MR fluid did not generate process scratches and pits, but could effectively remove the work-hardening and compressive residual stress, proving that MR fluid polishing method is a suitable pre-treatment process to produce nano-pores in the anodizing process.

Similar content being viewed by others

References

M. Michalska-Domańska, M. Norek, W. J. Stępniowski and B. Budner, Fabrication of high quality anodic aluminum oxide (AAO) on low purity aluminum—A comparative study with the AAO produced on high purity aluminum, Electrochim Acta, 105 (2013) 424–432, Doi: 10.1016/ j.electacta.2013.04.160.

G. E. J. Poinern, N. Ali and D. Fawcett, Progress in nanoengineered anodic aluminum oxide membrane development, Materials (Basel) (2010) Doi: 10.3390/ma4030487.

J. M. Montero-Moreno, M. Sarret and C. Müller, Some considerations on the influence of voltage in potentiostatic two-step anodizing of AA1050, J. Electrochem. Soc., 154 (2007) C169, Doi: 10.1149/1.2426880.

T. Aerts, I. De Graeve and H. Terryn, Anodizing of aluminium under applied electrode temperature: Process evaluation and elimination of burning at high current densities, Surf. Coatings Technol., 204 (2010) 2754–2760, Doi: 10.1016/j.surfcoat.2010.02.031.

J. M. Montero-Moreno, M. Belenguer, M. Sarret and C. M. Müller, Production of alumina templates suitable for electrodeposition of nanostructures using stepped techniques, Electrochim Acta, 54 (2009) 2529–2535, Doi: 10.1016/j.electacta.2008.03.067.

M. Michalska-Domańska et al., Fabrication of super slippery sheet-layered and porous anodic aluminium oxide surfaces and its anticorrosion property, Appl. Surf. Sci., 355 (2015) 487–526, Doi: 10.1016/j.corsci.2009.04.027.

P. Vengatesh and M. A. Kulandainathan, Hierarchically ordered self-lubricating superhydrophobic anodized aluminum surfaces with enhanced corrosion resistance, ACS Appl. Mater. Interfaces, 7 (2015) 1516–1526, Doi: 10.1021/ am506568v.

H. Cheng et al., Morphological characteristics of nanostructured surface using anodic aluminum template, Advances in Polymer Technology, 35 (2) (2015) 152–161, Doi: 10.1002/adv.21539.

M. T. Wu, I. C. Leu and M. H. Hon, Effect of polishing pretreatment on the fabrication of ordered nanopore arrays on aluminum foils by anodization, J. Vac. Sci. Technol. B Microelectron Nanom. Struct., 20 (2002) 776, Doi: 10.1116/1.1467657.

Y. Liu et al., One-step method for fabrication of biomimetic superhydrophobic surface on aluminum alloy, Colloids Surfaces A Physicochem. Eng. Asp., 466 (2015) 125–131, Doi: 10.1016/j.colsurfa.2014.11.017.

A. B. Kamaraj, V. Shaw and M. M. Sundaram, Novel fabrication of un-coated super-hydrophobic aluminum via pulsed electrochemical surface modification, Procedia Manuf., 1 (2015) 892–903, Doi: 10.1016/j.promfg.2015.09. 081.

S. Zheng et al., Fabrication of self-cleaning superhydrophobic surface on aluminum alloys with excellent corrosion resistance, Surf. Coatings Technol., 276 (2015) 341–348, Doi: 10.1016/j.surfcoat.2015.07.002.

S. D. Jacobs et al., An overview of magnetorheological finishing (MRF) for precision optics manufacturing, Ceram Trans., 102 (1999) 185–199.

S. D. Jacobs et al., MRF: Computer-controlled optics manufacturing, Am Ceram Soc. Bull, 78 (1999) 42–48.

Hassel, Surface treatment of NiTi for medical applications, Minim. Invasive Ther. Allied Technol., 13 (2004) 240–247. Doi: 10.1080/13645700410020278.

M. Bobji et al., Influence of surface roughness on the scatter in hardness measurements—a numerical study, Int. J. Rock Mech. Min. Sci., 36 (1999) 399–404, Doi: 10.1016/ S0148-9062(99)00009-1.

B. Wolf, Inference of mechanical properties from instrumented depth sensing indentation at tiny loads and indentation depths, Cryst. Res. Technol., 35 (2000) 377–399, Doi: 10.1002/1521-4079(200004)35:4<377::AID-CRAT377>3.0.CO;2-Q.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Haedo Jeong

Ki-Beom Kim is a Integrated Doctor’s student of Mechanical Engineering in Inha University from 2013. He received his B.S. from Inha University in Korea.

Rights and permissions

About this article

Cite this article

Kim, K.B., Kim, B.C., Ha, S.J. et al. Effect of pre-treatment polishing on fabrication of anodic aluminum oxide using commercial aluminum alloy. J Mech Sci Technol 31, 4387–4393 (2017). https://doi.org/10.1007/s12206-017-0838-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0838-1