Abstract

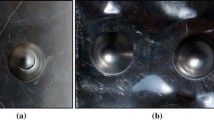

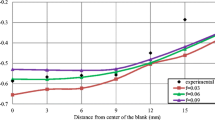

In this paper, deep drawing of conical and cylindrical cups without blank holder is investigated using a conical die design. These cups are produced by pushing circular blanks by pushing the flat head punch in a single stroke. ANSYS APDL 14.0 was then used to investigate the effects of die and punch geometry, half-cone angle, die and punch fillet radius, and drawing load. The thickness distribution of the cup was numerically investigated to determine the optimal process design, and mathematical analysis was adopted to determine the thickness distribution and longitudinal stress calculation. An experimental set-up was designed to validate the simulation results for conical and cylindrical shaped sheet-metal cups. Tensile tests were carried out to obtain the flow of the stress-strain curve for the simulation. The drawing characteristics of materials were investigated by performing Erichsen cupping and Vickers hardness tests. Experiments were conducted on blanks of aluminum alloys and stainless steel with initial thicknesses of 1.5 mm. A cylindrical cup of ss304 with LDR of up to 2.2 and conical cup of AA1100 with LDR of up to 2.7 were successfully achieved. Finite element simulation results showed good agreement with the mathematical and experimental results.

Similar content being viewed by others

References

M. M. N. Karima, A bifurcation study of wrinkling in deep drawing, Ph.D. Thesis (1980) 159.

R. Uday Kumar, Analysis of Fukui’s conical cup test, International Journal of Innovative Technology and Exploring Engineering, 2 (2013) 30–31.

B. Yamuna and A. C. Reddy, Finite element analysis of warm deep drawing process for conical cup of AA1080 aluminium alloy, International Journal of Advanced Research, 3 (2015) 1309–1317.

F. O. Neves, S. T. Button, C. Caminaga and F. C. Gentile, Numerical and experimental analysis of tube drawing with fixed plug, J. of the Braz. Soc. of Mech. Sci. & Eng., XXVII (2005) 425–431.

D. S. M. Salih and A. R. Ismail, Investigation die profile effect on nosing process using finite element method, Modern Applied Science, 5 (2) (2011) 1–5.

K. Geethalakshmi and A. O. Surendranathan, An investigation of containerless extrusion of Al-Zn-Mg alloys, Journal of Metallurgical Engineering, 2 (2013) 94–99.

M. Torkar, F. Tehovnik and B. Podgornik, Failure analysis at deep drawing of low carbon steels, Engineering Failure Analysis, 40 (2014) 1–7.

N. Ethiraj and V. S. Senthilkumar, Experimental investigation on warm deep drawing of stainless steel AISI 304, Applied Mechanics and Materials, 26 (2010) 436–442.

F. Saniee and M. H. Montazeran, A comparative estimation of the forming load in the deep drawing process, Journal of Materials Processing Technology, 140 (2003) 555–561.

V. Modanloo, A. Gorji and M. Bakhshi-Jooybari, Effects of forming media on hydrodynamic deep drawing, Journal of Mechanical Science and Technology, 30 (2016) 2237–2242.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Ajay Kumar Choubey is working as a Ph.D. Research Scholar in the Department of Material Science and Metallurgical Engineering at the Maulana Azad National Institute of Technology, Bhopal, India. He completed M.Tech. in Mechanical Engineering from Maulana Azad National Institute of Technology, Bhopal, India (2012). He has approximately 7 years of experience in the area of research, industry, and teaching. He also has more than 25 research publications in national and international journals, book chapters, and proceedings.

Rights and permissions

About this article

Cite this article

Choubey, A.K., Agnihotri, G. & Sasikumar, C. Experimental and mathematical analysis of simulation results for sheet metal parts in deep drawing. J Mech Sci Technol 31, 4215–4220 (2017). https://doi.org/10.1007/s12206-017-0819-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0819-4