Abstract

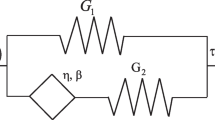

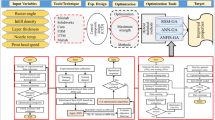

The current investigation was carried out to study the effect of vibratory welding technique on mechanical properties of 6 mm thick butt welded mild steel plates. A new concept of vibratory welding technique has been designed and developed which is capable to transfer vibrations, having resonance frequency of 300 Hz, into the molten weld pool before it solidifies during the Shielded metal arc welding (SMAW) process. The important process parameters of vibratory welding technique namely welding current, welding speed and frequency of the vibrations induced in molten weld pool were optimized using Taguchi’s analysis and Response surface methodology (RSM). The effect of process parameters on tensile strength and hardness were evaluated using optimization techniques. Applying RSM, the effect of vibratory welding parameters on tensile strength and hardness were obtained through two separate regression equations. Results showed that, the most influencing factor for the desired tensile strength and hardness is frequency at its resonance value, i.e. 300 Hz. The micro-hardness and microstructures of the vibratory welded joints were studied in detail and compared with those of conventional SMAW joints. Comparatively, uniform and fine grain structure has been found in vibratory welded joints.

Similar content being viewed by others

References

S. Kou and Y. Le, Nucleation mechanism and grain refining of weld metal, Welding Journal, 65 (1986) 63–70.

S. P. Tiwari, Effect of longitudinal vibration on mechanical properties of mild steel weldments, Proc. Instn Mech. Engrs, Part b, Journal of Engineering Manufacture, 207 (1993) 173–177.

L. Qinghua, C. Ligong and N. Chunzhen, Improving weld quality by vibratory weld conditioning, Materials Sci. and Engineering: A, 457 (2007) 246–253.

M. Malinowaski-Brodnicka, G. Den and W. J. Wink, Effect of magnetic fields on GTA welds in austenitic stainless steel, Welding Research Supplement, 52 (1990) 52–59.

C. Vives, Effect of electromagnetic vibration on the microstructure of continuously cast alloys, Material Science Engineering A, 173 (1993) 169–172.

W. Wu, Influence of vibration frequency on solidification of weldments, Scripta Matter, 42 (2000) 661–665.

A. Munsi, A. J. Waddell and C. A. Walker, The effect of vibratory stress on the welding microstructure and residual stress distribution, Journal of Materials: Design and Application, 215 (2001) 99–111.

M. Sun, Y. Sun and R. Wang, Vibratory stress relieving of welded sheet steels of low alloy high strength steel, Materials Letters, 58 (2004) 1396–1399.

D. Rao, D. Wang and L. Chen, The effectiveness evaluation of 314L stainless steel vibratory stress relief by dynamic stress, International Journal of Fatigue, 29 (2007) 192–196.

X. Jijin, C. Ligong and N. Chunzhen, Effect of vibratory welds conditioning on residual stress and distortion in the multipass girth butt welded pipes, International Journal of Pressure Vessel and Piping, 84 (2007) 298–303.

Y. Cui and X. Cl, Effect of ultrasonic vibration on un mixed zone formation, Scripta Mater., 55 (2006) 957–958.

Y. Lei, Z. Wang and X. Chen, Effect of ultrasound on microstructures and mechanical properties of plasma arc welded joints of SiCp/Al MMCs, Transaction of Nonferrous Metals Society of China, 21 (2011) 272–277.

R. Dehmolaei, M. Shamanian and A. Kermanpur, Effect of electromagnetic vibration on the unmixed zone formation in 25 Cr-35Ni heat resistant steel/Alloy 800 dissimilar welds, Materials Characterization, 59 (2008) 1814–1817.

K. Balasubramanian and V. Balusamykeshavan, Studies on the effect of vibration on hot cracking and grain size in AA7075 Aluminum alloy welding, International Journal of Engineering Science and Technology, 3 (2011) 681–686.

P. G. Rao, P. S. Rao, A. G. Krishna and M. M. M. Sarkar, Affect of vibratory welding process to improve the mechanical properties of butt welded joints, International Journal of Modern Engineering Research, 2 (2014) 2766–2270.

A Krajewski, W. Wlosinski, T. Chmielewski and P. Kolodziejczak, Ultrasonic vibration assisted arc-welding of aluminum alloys, Bulletin of the Polish Academy of Sciences and Technical Sciences, 4 (2012) 841–852.

V. Gholizadeh, Experimental investigation of the effect of vibration on mechanical properties of 304 stainless steel welded parts, International Journal of Advance Manufacturing Technology, 70 (2014) 1113–1124.

C.-C. Hsieh, P.-S. Wang, J.-S. Wang and W. Wu, Evolution of microstructure and residual stress under various vibration modes in 304 Stainless steel welds, The Scientific World Journal(2014).

T. Wen, S. Y. Liu, S. Che, L. Liu and C. Yang, Influence of high frequency vibration on microstructure and mechanical properties of TIG welding joints of AZ31 Magnesium alloy, Transaction of Nonferrous Metals Society of China, 25 (2015) 397–404.

S. Amini and M. Amiri, Study of ultrasonic vibration’s effect on friction stir welding, International Journal of Advance Manufacturing Technology, 73 (2014) 127–135.

S. D. Kumar et al., A Taguchi optimization of cooling slope process parameters for production of semi-solid A 356 alloy and A356-5TiB2 in-situ composite feedstock, Procedia Materials Science, 5 (2014) 232–241.

S. D. Kumar, P. R. Vundavilli and A. Mandal, Optimization of process parameters during machining of Thixoformed A 356-5TiB2 in-situ composite using design of experiments, International Conference on RACE 2015, Chennai(2015).

S. R. Das, D. Dhupal and A. Kumar, Study of surface roughness and flank wear in hard turning of AISI 4140 steel with coated ceramics inserts, Journal of Mechanical Sciences and Technology, 29 (10) (2015) 4329–4340.

R. Kumar and M. Balasubramanian, Application of response surface methodology to optimize process parameters in friction welding of Ti-6Al-4V and SS304L rods, Transaction of Nonferrous Metals Society of China, 25 (2015) 3625–3633.

N. Kiaee and M. Aghaie-Khafri, Optimization of gas tungsten arc welding process by surface methodology, Materials & Design, 54 (2014) 25–31.

P. K. Singh, D. Patel and S. B. Prasad, Optimization of process parameters during vibratory welding technique using Taguchi’s analysis, Perspectives in Sciences, 8 (2016) 399–402.

P. K. Singh, D. Patel and S. B. Prasad, Development of vibratory welding technique and tensile properties investigation of Shielded metal arc welded joints, Indian Journal of Science and Technology, 9 (2016) 35.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

S. Deepak Kumar is an Assistant Professor in Manufacturing Engineering Department, National Institute of Technology, Jamshedpur, India. He has completed his Ph.D. from Indian Institute of Technology, Bhubaneswar. His research area of interest is Advance manufacturing processes and computational designing.

Pravin Kumar Singh is a Ph.D. student at the Department of Manufacturing Engineering, National Institute of Technology, Jamshedpur, India doing research on vibratory welding technology. He received his M.Tech. from SLIET, India in 2011.

D. Patel is an Assistant Professor in Manufacturing Engineering department, National Institute of Technology, Jamshedpur, India. He has completed his Ph.D. from Ranchi University, India. His research interest includes Industrial engineering, Welding, Fuzzy system, and Production technology.

S. B. Prasad is an Associate Professor in Manufacturing Engineering Department, National Institute of Technology, Jamshedpur, India. He has completed his Ph.D. from IIT Roorkee, India. His research interest includes solar energy, Machine design, Welding metallurgy and Energy management.

Rights and permissions

About this article

Cite this article

Singh, P.K., Kumar, S.D., Patel, D. et al. Optimization of vibratory welding process parameters using response surface methodology. J Mech Sci Technol 31, 2487–2495 (2017). https://doi.org/10.1007/s12206-017-0446-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0446-0