Abstract

Machining of aerospace and biomedical grade titanium alloys has always been a challenge because of their low conductivity and elastic modulus. Different machining methods and parameters have been adopted for high precision machining of titanium alloys. Machining of titanium alloys can be improved by microstructure optimization. The present study focuses on the effect of microstructure on machinability of Ti6Al4V alloys at different cutting speeds. Samples were subjected to different annealing conditions resulting in different grain sizes and local micro-strains (misorientation). Cutting forces were significantly reduced after annealing; consequently, sub-surface residual stresses were reduced. Deformation twinning was also observed on samples annealed at a higher temperature due to larger grain size. Initial strain free grains and deformation twinning during machining reduces the cutting force at higher cutting speed.

Similar content being viewed by others

References

C. Leyens and M. Peters, Titanium and Titanium Alloys(2003).

E. O. Ezugwu, Key improvements in the machining of difficult-to-cut aerospace superalloys, Int. J. Mach. Tools Manuf., 45 (2005) 1353–1367.

S. M. Ratchev, S. M. Afazov, A. A. Becker and S. Liu, Mathematical modelling and integration of micro-scale residual stresses into axisymmetric FE models of Ti6Al4V alloy in turning, CIRP J. Manuf. Sci. Technol., 4 (2011) 80–89.

A. R. Zareena and S. C. Veldhuis, Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium, J. Mater. Process. Technol., 212 (2012) 560–570.

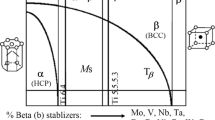

P. J. Arrazola, A. Garay, L. M. Iriarte, M. Armendia, S. Marya and F. Le Maître, Machinability of titanium alloys (Ti6Al4V and Ti555.3), J. Mater. Process. Technol., 209 (2009) 2223–2230.

R. R. Boyer, An overview on the use of titanium in the aerospace industry, Mater. Sci. Eng. A, 213 (1996) 103–114.

G. Bartarya and S. K. Choudhury, State of the art in hard turning, Int. J. Mach. Tools Manuf., 53 (2012) 1–14.

A. J. Makadia and J. I. Nanavati, Optimisation of machining parameters for turning operations based on response surface methodology, Meas. J. Int. Meas. Confed., 46 (2013) 1521–1529.

S. Palanisamy, S. D. McDonald and M. S. Dargusch, Effects of coolant pressure on chip formation while turning Ti6Al4V alloy, Int. J. Mac,. Tools Manuf., 49 (2009) 739–743.

R. A. R. Rashid, S. Sun, G. Wang and M. S. Dargusch, The effect of laser power on the machinability of the Ti-6Cr-5Mo-5V-4Al beta titanium alloy during laser assisted machining, Int. J. Mach. Tools Manu., 63 (2012) 41–43.

T. Akasawa, I. Fukuda, K. Nakamura and T. Tanaka, Effect of microstructure and hardness on the machinability of medium-carbon chrome-molybdenum steel, J. Mater. Process. Techno., 153–154 (2004) 48–53.

A. Molinari, C. Musquar and G. Sutter, Adiabatic shear banding in high speed machining of Ti-6Al-4V: Experiments and modeling, Int. J. Plas., 18 (2002) 443–459.

P. Crawforth, B. Wynne, S. Turner and M. Jackson, Subsurface deformation during precision turning of a nearalpha titanium alloy, Scr. Mater., 67 (2012) 842–845.

I. S. Jawahir, E. Brinksmeier, R. M’Saoubi, D. K. Aspinwall, J. C. Outeiro, D. Meyer, D. Umbrello and A. D. Jayal, Surface integrity in material removal processes: Recent advances, CIRP Ann. -Manuf. Technol., 60 (2011) 603–626.

M. R. Shankar, B. C. Rao, S. Lee, S. Chandrasekar, A. H. King and W. D. Compton, Severe plastic deformation (SPD) of titanium at near-ambient temperature, Acta Mate., 54 (2006) 3691–3700.

W. Bin Rashid, S. Goel, X. Luo and J. M. Ritchie, The development of a surface defect machining method for hard turning processes, Wear, 302 (2013) 1124–1135.

A. Ebrahimi and M. M. Moshksar, Evaluation of machinability in turning of microalloyed and quenchedtempered steels: Tool wear, statistical analysis, chip morphology, J. Mater. Process. Technol., 209 (2009) 910–921.

M. M. Nowell and S. I. Wright, Orientation effects on indexing of electron backscatter diffraction patterns, Ultramicroscopy, 103 (2005) 41–58.

D. Kohli, R. Rakesh, V. P. Sinha, G. J. Prasad and I. Samajdar, Fabrication of simulated plate fuel elements: Defining role of stress relief annealing, J. Nucl. Mater., 447 (2014) 150–159.

S. Joshi, P. Pawar, A. Tewari and S. S. Joshi, Influence of ß phase fraction on deformation of grains in and around shear bands in machining of titanium alloys, Mater. Sci. Eng. A, 618 (2014) 71–85.

V. P. Astakhov and S. Shvets, The assessment of plastic deformation in metal cutting, J. Mater. Process. Technol., 146 (2004) 193–202.

V. P. Astakhov and S. V. Shvets, A novel approach to operating force evaluation in high strain rate metaldeforming technological processes, J. Mater. Process. Technol., 117 (2001) 226–237.

F. J. Humphreys, Grain and subgrain characterisation by electron backscatter diffraction, J. Mater. Sci., 36 (2001) 3833–3854, doi:10.1023/A:1017973432592.

S. I. Wright, M. M. Nowell, R. de Kloe, P. Camus and T. Rampton, Electron imaging with an EBSD detector, Ultramicroscopy, 148 (2015) 132–145.

S. K. Mishra, S. S. V. Tatiparti, S. M. Tiwari, R. S. Raghavan, J. E. Carsley and J. Li, Annealing response of AA5182 deformed in plane strain and equibiaxial strain paths, Philos. Mag., 93 (2013) 2613–2629.

J. D. P. Velásquez, A. Tidu, B. Bolle, P. Chevrier and J.-J. Fundenberger, Sub-surface and surface analysis of high speed machined Ti-6Al-4V alloy, Mater. Sci. Eng. A, 527 (2010) 2572–2578.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Nam-Su Huh

Sagar V. Telrandhe is a Ph.D. candidate in Mechanical Engineering, Department of Mechanical Engineering, IIT Bombay, Powai, Mumbai, India. His Ph.D. research work deals with the study of existing problems associated with Titanium alloys machining and finding the possible microstructural modification which can improve its machining. His research areas are FEM, Machining mechanics and Microstructural characterization.

Rights and permissions

About this article

Cite this article

Telrandhe, S.V., Saxena, A.K. & Mishra, S. Effect of microstructure and cutting speed on machining behavior of Ti6Al4V alloy. J Mech Sci Technol 31, 2177–2184 (2017). https://doi.org/10.1007/s12206-017-0413-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0413-9