Abstract

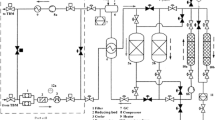

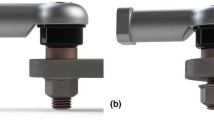

In order to increase the reliability of a separation device for a small satellite, a new non-explosive separation device is invented. This device is activated using a thermal cutting method with a Ni-Cr wire. A reliability analysis is carried out for the proposed non-explosive separation device by applying the Fault tree analysis (FTA) method. In the FTA results for the separation device, only ten single-point failure modes are found. The reliability modeling and analysis for the device are performed considering failure of the power supply, the Ni-Cr wire burns failure and unwinds, the holder separation failure, the balls separation failure, and the pin release failure. Ultimately, the reliability of the proposed device is calculated as 0.999989 with five Ni-Cr wire coils.

Similar content being viewed by others

References

E. R. Fosness, S. J. Buckley and W. F. Gammill, Deployment and release devices efforts at the air force research laboratory space vehicles directorate, AIAA Space 2001 Conference and Exposition, Albuquerque, NM (2001).

K. Y. Chang, Pyrotechnic devices, shock levels and their applications, 9th International Congress on Sound and Vibration Orlando, USA (2002).

C. J. Moening, Pyroshock flight failures, Proceedings of 31st Annual Technical Meeting of the Institute of Environmental Sciences (IES), 3 (1985).

J. Müller and C. Zauner, Low shock release unit-easy resettable and 100% reusable, 10th European Space Mechanisms and Tribology Symposium, 524 (2003) 107–112.

D. Dowen, S. Christiansen and A. Peffer, Development of a reusable, low-shock clamp band separation system for small spacecraft release applications (2001).

J. Vázquez and J. Bueno, Non explosive low shock reusable 20 kN hold-down release actuator, European Space Agency-Publications-ESA SP, 480 (2001) 131–136.

O. Duforet, B. Bonduelle, G. Valembois, D. Dilhan and J. Sicre, New concept of a resettable ultra low shock actuator (RULSA), ESMATS 2011 (2011) 297–304.

C. Laa, T. Nitschko, L. Supper, G. Traxler and J. M. Lautier, Unlimited resettable no-shock hold-down and release mechanism, Proc. of the 14th European Space Mechanisms and Tribology Symposium (2011) 385–388.

M. S. Cho, H. S. Hwang, M. H. Lee, B. Kim and M. R. Zinn, A screwjack mechanism based separation device driven by a piezo actuator, International Journal of Precision Engineering and Manufacturing, 13 (11) (2012) 2079–2082.

W. Tak, M. Lee and B. Kim, Ultimate load and release time controllable non-explosive separation device using a shape memory alloy actuator, Journal of Mechanical Science and Technology, 25 (5) (2011) 1141–1147.

M. S. Lee, J. U. Jo, W. J. Tak and B. Kim, Shape memory alloy (SMA) based non-explosive separation actuator (NEA) with a redundant function, International Journal of Precision Engineering and Manufacturing, 12 (3) (2011) 569–572.

H. S. Hwang, B. Kim and J. W. Choi, A compact nonexplosive separation device for high preload and low shock, International Journal of Precision Engineering and Manufacturing, 15 (1) (2014) 83–88.

Y. Wei-yuan, Classification of space mechanism & reliability research, Spacecraft Engineering, 3 (1994) 31–39.

B. Kim and H. S. Hwang, Non-explosive separation device, Korean patents, 10-1406925.

Q. Lin, H. Nie, J. Ren and J. Chen, Investigation on design and reliability analysis of a new deployable and lockable mechanism, Acta Astronautica, 73 (2012) 183–192.

M. Stamatelatos et al., Fault tree handbook with aerospace applications (2002).

Nonelectronic Parts Reliability Data 2011 from RIAC.

X. Ning-Cong, L. Yan-Feng and H. Hongzhong, Reliability analysis method of deployment mechanism of a satellite solar arrays, Journal of Astronautics, 4 (2009) 065.

Y. Yang, S. Yan, L. Xie and J. Wu, Failure analysis of deployment mechanism of a satellite solar array, Reliability, Maintainability and Safety (ICRMS), 2011 9th International Conference on, IEEE (2011) 931–937.

J. H. Berk, Reliability Comparison Non-Explosive Separation Nut MODEL SN9723-3 [P/N 65390]_& ‘ALTERNATE’ SOURCE Non-Explosive Separation Nut MODEL # 9103, Hi-shear Technology Corporation.

Hi-shear Technology Corporation, Separation Nuts (Pyrotechnic or Non-Pyrotechnic), http://www.hstc.com/Products/.

TiNi Aerospace, Frangibolt, Pinpuller, Ejector Release Mechanism, http://www.tiniaerospace.com/products.html (Accessed 17 Dec. 2013).

Cooper Industries, Non-Explosive Actuators, http://www.cooperindustries.com.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jin Weon Kim

Junwoo Choi received his B.S. and M.S. degrees from Korea Aerospace University, Korea, in 2013 and 2015, respectively, and is now Doctorate course in Korea Aerospace University. His major research interests include mechanical designs for deployable and locking device.

Kukha Hwang received his B.S. degree from Korea Aerospace University, Korea, in 2015, and is now Master course in Korea Aerospace University. His major research interests include mechanical designs for deployable device.

Byungkyu Kim received his Ph.D. in Mechanical Engineering from the University of Wisconsin, Madison, in 1997. From 1997 to 2000, he was a Research Associate of Center for X-ray Lithography in the University of Wisconsin. From 2000 to 2005, he worked for Microsystem Center of KIST as a Principal Research Scientist. He was in charge of developing the microrobot for a microcapsule-type endoscope. Currently, he is a Professor in the School of Aerospace and Mechanical Engineering in Korea Aerospace University. His major interests are mechanical designs and analysis for spacecraft mechanism.

Rights and permissions

About this article

Cite this article

Choi, J., Hwang, K. & Kim, B. Reliability analysis for thermal cutting method based non-explosive separation device. J Mech Sci Technol 30, 5433–5438 (2016). https://doi.org/10.1007/s12206-016-1111-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-1111-8