Abstract

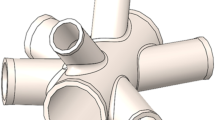

Sulfur polymer concrete (SPC) is a relatively new material used to replace Portland cement for manufacturing sewer pipes. The objective of this work is to develop an efficient molding machine with an inner rotating die to mix, compress and shape the SPC pipe. First, the alternative concepts were generated based on the TRIZ principles to overcome the drawbacks of existing machines. Then, the concept scoring technique was used to identify the best design in terms of machine structure and product quality. Finally, topology optimization was applied with the support of the density method to reduce mass and to displace the inner die. Results showed that the die volume can be reduced by approximately 9% and the displacement can be decreased by approximately 3% when compared with the initial design. This work is expected to improve the manufacturing efficiency of the concrete pipe molding machine.

Similar content being viewed by others

References

OCPA concrete pipe design manual, Ontario Concrete pipe association, Burlington, Canada (2002).

Y. Zhou, W. M. Huang, S. F. Kang, X. L. Wu, H. B. Lu, J. Fu and H. Cui, From 3D to 4D printing: approaches and typical applications, Journal of Mechanical Science and Technology, 29 (10) (2015) 4281–4288.

http://rccpipemachinery.cn/htm/products/concrete/centrifug al/2013/0916/69.html.

V. Souchkov, TRIZ: A systematic approach to conceptual design, Ideal Design Solution, Netherlands (1988).

D. Lee and S. Shin, Extended-finite element method as analysis model for Gauss point density topology optimization method, Journal of Mechanical Science and Technology, 29 (4) (2015) 1341–1348.

D. Serban, E. Man, N. Ionescu and T. Roche, A TRIZ approach to design for environment, Product Engineering (2004) 89–100.

H. Hua, Z. Liao and J. Song, Vibration reduction and firing accuracy improvement by natural frequency optimization of a machine gun system, Journal of Mechanical Science and Technology, 29 (9) (2015) 3635–3643.

A. Xiao, S. S. Park and T. Freiheit, A comparison of concept selection in concept scoring and axiomatic design methods, University of Calgary, Canada.

M. Zurofi, Manufacturing process effects on fatigue design and optimization of automotive components-an analytical and experimental study, The University of Toledo (2004).

K.-S. Yoo and S.-Y. Han, Topology optimum design of compliant mechanisms using modified ant colony optimization, Journal of Mechanical Science and Technology, 29 (8) (2014) 3321–3327.

Y. Kojima, Mechanical CAE In Automotive Design, R&D review of Toyota CRLD, 35 (4) (2000).

Altair OptiStruct, HyperWorks 10.0 User’s manual, Altair Engineering, Inc.

M. P. Bendsøe and O. Sigmund, Topology optimization-theory, methods and applications, Springer, Berlin, Germany (2004).

S. Y. Kim, Y. Kim and C. K. Mechefske, A A new efficient convergence criterion for reducing computational expense in topology optimization: Reducible design variable method, International Journal For Numerical Methods In Engineering, 90 (2012) 752–783.

K. T. Zuo, L. P. Chen, Y. Q. Zhang and J. Yang, Study of key algorithms in topology optimization, The International Journal of Advanced Manufacturing Technology, 32 (7–8) (2007) 787–796.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jeong Sam Han

Hong-Seok Park received his Dr.-Ing. degree from the University of Hannover in 1992. He is now a Professor in the School of Mechanical and Automotive Engineering at the University of Ulsan in Korea. His research interests include intelligent manufacturing systems, digital manufacturing techniques and CAD/CAM/CAE.

Trung-Thanh Nguyen received his Master’s degree from Hanoi Univeristy of Science and Technology in 2012. His research interests include multi-objective optimization, energy efficient manufacturing process and CAD/CAM/CNC/CAE.

Prakash Dahal received his B.E. in Mechanical Engineering from Kathmandu University in Nepal in 2007. He received his Master’s degree in Mechanical Engineering from the University of Ulsan in Korea in 2012 under the guidance of Prof. Hong-Seok Park.

Rights and permissions

About this article

Cite this article

Park, H.S., Nguyen, T.T. & Dahal, P. Development of a new concrete pipe molding machine using topology optimization. J Mech Sci Technol 30, 3757–3765 (2016). https://doi.org/10.1007/s12206-016-0738-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0738-9