Abstract

In this paper, a thixoforging method is studied as one of the semi-solid forming processes. At the first step, the influence of semi-solid temperature, holding time, and ram speed of the hydraulic press are investigated on microstructure and mechanical properties of thixoforged A356 aluminum alloy parts. For this purpose, the slope plate casted billets are heated up to semi-solid temperature of 580, 590, and 600°C and holding time of 5, 10, and 15 minutes and then are deformed using the press with ram speeds of 1, 3 and 5 mm/s. Results show that the best mechanical properties are related to the thixoforged specimen with the finest microstructure which is thixoforged at semi-solid temperature of 600°C, holding time of 5 minutes and ram speed of 5 mm/s. Afterwards, the T6 heat treatment is performed to improve mechanical properties of parts produced by thixoforging process. At the final step of experiments in order to investigate the effect of using slope plate prior to reheating on microstructure and mechanical properties, semi-solid forging is done by using the gravity casted billet.

Similar content being viewed by others

References

H. Atkinson, Modelling the semisolid processing of metallic alloys, Progress in Materials Science, 50 (3) (2005) 341–412.

Y. Birol, A357 thixoforming feedstock produced by cooling slope casting, Journal of Materials Processing Technology, 186 (1) (2007) 94–101.

L. Khizhnyakova, M. Ewering, G. Hirt, K. Bobzin and N. Bagcivan, Metal flow and die wear in semi-solid forging of steel using coated dies, Transactions of Nonferrous Metals Society of China, 20 (2010) 954–960.

H. Kim and C. Kang, Vacuum-assisted rheo-forging process of A356 aluminum alloys, International Journal of Machine Tools and Manufacture, 48 (15) (2008) 1626–1636.

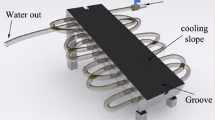

S. Nourouzi, S. M. Ghavamodini, H. Baseri, A. Kolahdooz and M. Botkan, Microstructure evolution of A356 aluminum alloy produced by cooling slope method, Advanced Materials Research, 402 (2012) 272–276.

S. S. Hosseini, S. Nourouzi, S. J. Hosseinipour and A. Kolahdooz, Effect of slope plate variable and pouring temperature on semi-solid microstructure of A356 aluminum alloy, Steel Metal Research, Special Issue of Metal Forming (2012) 779–782.

H. Baseri, S. Nourouzi, A. Kolahdooz and S. M. Ghavamodini, Optimization of semi-solid metal processing of A356 aluminum alloy, Journal of Mechanical Science and Technology, 27 (12) (2013) 3869–3874.

S. Tahamtan and A. F. Boostani, Microstructural characteristics of thixoforged A356 alloy in mushy state, Transactions of Nonferrous Metals Society of China, 20 (2010) 781–787.

N. Mahathaninwong, T. Plookphol, J. Wannasin and S. Wisutmethangoon, T6 heat treatment of rheocasting 7075 Al alloy, Materials Science and Engineering A, 532 (2012) 91–99.

A. Kolahdooz, S. Nourouzi, M. Bakhshi and S. J. Hosseinipour, Investigation of the controlled atmosphere of semisolid metal processing of A356 aluminium alloy, Journal of Mechanical Science and Technology, 28 (10) (2014) 4267–4274.

A. Kolahdooz, S. Nourouzi, M. B. Jooybari and S. J. Hosseinipour, Experimental investigation of thixoforging parameters effects on the microstructure and mechanical properties of the helical gearbox cap, Journal of Mechanical Science and Technology, 28 (10) (2014) 4257–4265.

N. Barman, P. Kumar and P. Dutta, Studies on transport phenomena during solidification of an aluminum alloy in the presence of linear electromagnetic stirring, Journal of Materials Processing Technology, 209 (18) (2009) 5912–5923.

N. Haghdadi, A. Zarei-Hanzaki, S. Heshmati-Manesh, H. R. Abedi and S. B. Hassas-Irani, The semisolid microstructural evolution of a severely deformed A356 aluminum alloy, Materials & Design, 49 (2013) 878–887.

G. Yan, S. Zhao, S. Ma and H. Shou, Microstructural evolution of A356.2 alloy prepared by the SIMA process, Materials Characterization, 69 (2012) 45–51.

D. Liu, H. V. Atkinson, P. Kapranos, W. Jirattiticharoean and H. Jones, Microstructural evolution and tensile mechanical properties of thixoformed high performance aluminium alloys, Materials Science and Engineering A, 361 (1) (2003) 213–224.

J. Jiang, Y. Wang and H. Atkinson, Microstructural coarsening of 7005 aluminum alloy semisolid billets with high solid fraction, Materials Characterization, 90 (2014) 52–61.

S. B. Hassas-Irani, A. Zarei-Hanzaki, B. Bazaz and A. A. Roostaei, Microstructure evolution and semi-solid deformation behavior of an A356 aluminum alloy processed by strain induced melt activated method, Materials & Design, 46 (2013) 579–587.

V. Pouyafar, S. Sadough, F. Hosseini and M. Rahmani, Design of experiments for determination of influence of different parameters on mechanical properties of semi-solid extruded parts, Transaction of Nonferrous Material Society of china, 20 (2010) 794–797.

C. Ayas, V. Deshpande and M. Geers, Tensile response of passivated films with climb-assisted dislocation glide, Journal of the Mechanics and Physics of Solids, 60 (9) (2012) Fig. 20. Stress-strain diagram of semi-solid forged products. 1626–1643.

J.h. Peng, X.l. Tang, J. T. He and D. Y. Xu, Effect of heat treatment on microstructure and tensile properties of A356 alloys, Transactions of Nonferrous Metals Society of China, 21 (9) (2011) 1950–1956.

H. Möller, G. Heinrich, S. Gonasagren, E. Waldo and R. D. Knutsen, Influence of temper condition on microstructure and mechanical properties of semisolid metal processed Al- Si-Mg alloy A356, International Journal of Cast Metals Research, 22 (6) (2009) 417–421.

M. Zhu, Z. Jian, G. Yang and Y. Zhou, Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys, Materials & Design, 36 (2012) 243–249.

L. B. Chao, P. Y. Koo and D. H. Sheng, Effects of rheocasting and heat treatment on microstructure and mechanical properties of A356 alloy, Materials Science and Engineering A, 528 (3) (2011) 986–995.

Y. Harada, S. Tamura and S. Kumai, Effects of hightemperature solutionizing on microstructure and tear toughness of A 356 cast aluminum alloy, Keikinzoku/Journal of Japan Institute of Light Metals, 61 (5) (2011) 213–219.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Cheol Ko

Alborz Kazemi is a M.Sc. student of Mechanical Engineering at Babol University of Technology in Iran. His research interests are Design and Manufacturing and semi-solid forming.

Rights and permissions

About this article

Cite this article

Kazemi, A., Nourouzi, S., Kolahdooz, A. et al. Experimental investigation of thixoforging process on microstructure and mechanical properties of the centrifugal pump flange. J Mech Sci Technol 29, 2957–2965 (2015). https://doi.org/10.1007/s12206-015-0626-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0626-8